Kartoshka chiplari mashinalari frantsuz kartoshkalari mashinasi Avtomatik kartoshka chiplari liniyasi

Kartoshka chiplari mashinasi Kartoshkada xom kartoshka uskunalari qovurilgan kartoshka chiplari ichiga.

Avtomatik kartoshka chiplari liniyasi kartoshka yuvish va peshona mashinasi, Chips Kester mashinasi, Kartoshka uchun blanching mashinasi, Kartoshka chiplari Dewastering Mashinasi, kartoshka chiplari qovuradi, deholing mashinasi, sovutish mashinasi, Kartoshka chiplari ziravor mashinasi, Kartoshka chiplarini qadoqlash mashinasi va uning yordamchi uskunalari va funktsiyalari butun liniyani doimiy ravishda avtomatik ravishda avtomatik ravishda ishlash uchun.

Qo'llaniladi: Kartoshka chiplari, fri kartoshkasi, o'tloq chiplari va boshqalar.

Sig'im: 50-100kg / h, 100-150kg / h, 200-250kg / h, 350-400kg / h, 450-500kg / h, va yuqori quvvat.

Kartoshka chip mashinalar qo'llanilishi

Kartoshka chiplari mashinasi Kartoshka chiplari zavodida kattaroq yoki o'rtacha kartoshka qayta ishlash zavodi bilan ishlatiladi. Yuqori ishlab chiqarish samaradorligi va gigiena oziq-ovqat tufayli,To'liq avtomatik kartoshka chiplari liniyasi investorlarni kam ishlab chiqarishning kamroq va bozor ulushi bilan ta'minlaydi, Shuning uchun investitsiyalarni yanada yaxshilash.

Va, Kichik shkala kartoshka chiplarini tayyorlash mashinasi Kichik biznesni boshlashni rejalashtirgan oziq-ovqat mahsulotlarini qayta ishlash kompaniyasi uchun juda yaxshi.

Bundan tashqari, Chiplar uchun mashina barmoq chiplarini tayyorlash uchun chiziqni sozlashi mumkin, banan chiplari , shirin kartoshka chiplari, va hokazo.

Kartoshka chiplari mashinasi

Kartoshka chiplari ishlab chiqarish tavsifi

Kartoshka chiplari tayyorlash mashinasi kartoshka yuvish mashinasi kartoshka qayta ishlash eritmasi, po'choq, g'alayon, qovurish, ziravor va qadoqlash. Va chip chiziqlari yuqori sig'im, Malakali va gigiena ovqatlari bilan super samaradorlik.

Turli xil biznes talabini qondirish uchun, 20-50 kg / soat / soat / soat / s gacha bo'lgan yarim avtomatik kartoshka chiplari ishlab chiqarish liniyasini yaratdik. But also we designed potato chips fully automatic machine with capacity upto 500KG/H and higher capacity can be customized.

Kartoshka chiplari ishlab chiqaruvchi mashina spetsifikatsiyasi

Isitish usuli: Elektr isitish / Gaz isitish

Mashinalar materiallari: Oziq-ovqat darajasi 304 Zanglamaydigan po'latli materiallar, eng yaxshi sifat

Yog 'isitish harorati: 0℃ 300 ℃ dan (farangeyt 32 ° F ga qadar) 572.0 ° FIL

Kartoshka va kartoshka chiplarining nisbati: 4 : 1 Adabiyotlar uchun.

Sig'im: 50Kg / h 500 kg / soat (yuqori quvvatli chiplar ishlab chiqaruvchisi sozlanishi mumkin)

Zavod kosmik ehtiyojlari: Biz zavod hajmi va pol rejasi asosida ishlab chiqarish liniyasini sozlashimiz mumkin.

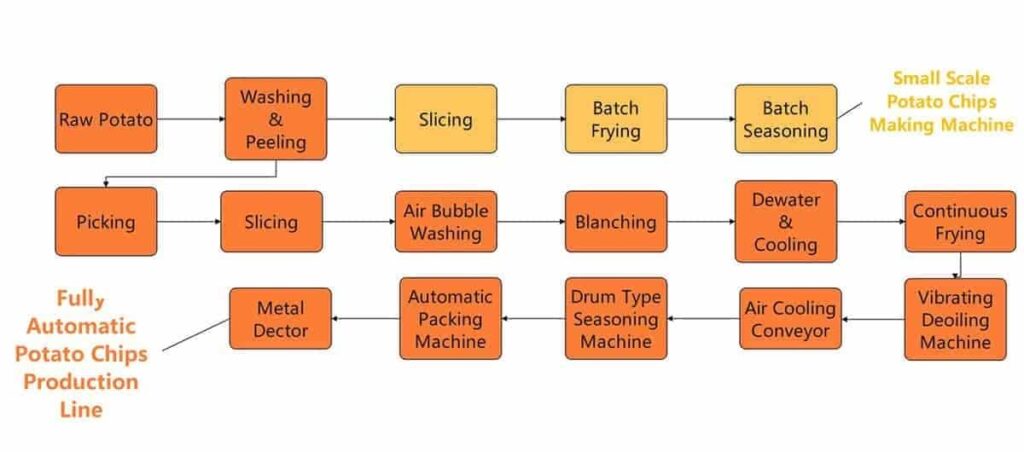

Kartoshka chiplari ishlab chiqarish liniyasi oqimi jadvali

Kartoshka chip ishlab chiqarish liniyasi xususiyatlari

Kartoshka peeling mashinasi

Mall o'lchovi uchun chiplar ishlab chiqarish liniyasi, bkartoshka peeling mashinalari qo'lda ishlashdan ko'ra samarali yuvish va undan yuqori peeling tezligining afzalligi.

Va to'liq avtomatik kartoshka chiplari ishlab chiqarish liniyasi uchun, Bu doimiy kartoshkani yuvish va peeling mashinasini olish shartnomasi. Lift bilan ishlash, U doimiy xom kartoshkani boqishini amalga oshiradi, yuvish, Peoping va oqindi jarayonlari.

Bundan tashqari, Spriting turi peeling mashinasi, pichoqlash jarayonidan oldin konveyerlar kamarini olish uchun kartoshka chuqur va ikkinchisini tushirish.

Shu sababli, Avtomatik kartoshka peeling mashinasi o'rtacha va kattaroq kartoshka chiplari ishlab chiqarish liniyasida qo'llaniladi.

Bundan tashqari, Bu kartoshka yuvish va tozalash uchun javob beradi, Shirin kartoshka, kassvana, zanjabil, piyoz, sabzi va boshqalar.

Chiplar sicer mashinasi

Kartoshka to'ng'ich mashinasi kartoshka tilimlarini hatto qalinligi bilan kesib tashlashi mumkin. Va tong qalinligi ehtiyoj bo'yicha sozlanishi mumkin.

Bundan tashqari, Ishlab chiqarish quvvatiga asoslangan kartoshka chip to'ng'ichi mashinasining turli xil modellari mavjud.

Qovurishdan oldin kartoshka puflash

Katta quvvatli avtomatik kartoshka chiplari ishlab chiqarish liniyasida, Blanching mashinasi chip rangini himoya qilish uchun muhim rol o'ynaydi va ta'mga ega.

Kartoshka chiplari tarqalishi haqida 5 TO15 daqiqada issiq suv haroratida 70 y. (158.0 °F)

Tanlash uchun mijoz uchun elektr isitish va elektr isitish vositasi bo'lgan doimiy ravishda filial mashinasi mavjud.

Bundan tashqari, Moslash mashinasi nafaqat kartoshka chiplarini tarash uchun ham yaxshi, Ammo banan chiplari ham, Frantsuz qovurilgan va boshqa materiallar.

Kartoshka deveaterizatsiya mashinasi

Havo sovutish mashinasi suvni olib tashlaydi va qovurishdan oldin, kartoshka chiplarining haroratini sovutishadi.

Va yaxshiroq ta'sir ko'rsatish, Vibratsiyalashgan dehqonchilik maskasini havo quritish va devatbiyotlarni konveyer konveyer konveyerga o'tkazish shartidir.

Kartoshka qovurish mashinasi

Kichik shkala kartoshka chiplari o'simliklari uchun, yarim avtomatik qovurish chizig'i - bu turli xil barmoqlarni qovurish.

Biroq, Avtomatik chiplar ishlab chiqarish zavodi uchun, bu uzluksiz qovurish mashinasi qovurilgan vaqtni kengroq va kamroq mehnat bilan ishlashni davom ettirish uchun talab qilinadi. Va qovurilgan chiplar hatto qovurilgan rang va yaxshi ta'mga ega bo'lishi kerak. Bundan tashqari, Neftni to'ldirish tizimi, Neft qayta ishlash tizimi, Neft filtrlash tizimi va mashinani tozalash tizimi ishlab chiqarish samaradorligini oshiradi, Neftdan foydalanish va boytum sifatli chiplarni uzaytiring.

Deholing mashinasi

Qovurilganidan keyin qovurilgan chiplarda yog 'tushirish uchun tebranish mashinasi.

Chunki, Qovurilgan chiplar qovurilgan chiplar odatda, bu mahsulotni yog'li va poliga puflashi mumkin bo'lgan yog 'olib yuradi. Shu sababli, Neftni qabul qiluvchi plitalari bo'lgan tebranuvchi mashinasi chip yuzidan moyni yo'q qilish va ishlab chiqarish joyini toza saqlash yaxshi.

Ko'proq narsa, tebranish jarayonida, Chiplar chuqur harakatlanmoqda va keyingi jarayonga qadar tarqalmoqda.

Sovutish mashinasi

Sovutish konveyeri shamolni chiplarga tashlaydigan shamollatish vositasi bilan o'rnatiladi. Shuning uchun chiplar haroratni tabiiy kuchli shamol bilan pasaytiradi. Bu ziravor va qadoqlash jarayonidan oldin muhim jarayon. To'liq sovutish chiplari yanada yorug 'bo'ladi va uzoqroq yaroqlilik muddatiga ega bo'ladi.

Ixtiyoriy dizayn: Shamolga chidamli ret - bu konveyer kamarlarini o'chirish uchun chiplarni oldini olish shart.

Va sovutish konveyer ostidagi yog 'plitasi, chiplardan qo'shilgan har qanday qo'shimcha yog'ni olish majburiydir.

Kartoshka chip mavsuz mashinasi

Baraban tipidagi mavsumolish chang mavsumiy bilan ishlaydi, achchiq mavsumiy, tuz, va shuningdek, yog 'püskürtme va boshqalar bilan ta'minlash mumkin. Ishlab chiqarish ehtiyojiga ko'ra.

Chiplar chizig'i uchun, Chiplarni sovutishdan keyin, konveyer ziravorlarni chiplar bilan bir tekis aralashtirish uchun barabanni doimiy ravishda yuborish shartidir.

Va chiqish joyida, Qo'shimcha ziravorlar va chiqindilarni qabul qilishning plastinkaga tushishiga imkon beradigan to'rlar mavjud. Ushbu dizayn tufayli, Chaqirlar shunchaki ziravorlar va ajoyib ta'mga ega.

Tarozi bilan avtomatik avtomatik mashina, To'ldirish va sumka qilish

Chiplarni avtomatik ravishda plastik sumkaga joylashtiring, Avtomatik chiplarni qadoqlash mashinasi ideal tanlovdir. Normal holatda, Avtomatik chiplarni qadoqlash mashinasi liftni o'z ichiga oladi, ko'p boshli diktor, kvartira, Sana bilan sana bilan o'ralgan asboblar, va oxirgi mahsulot konveyeri.

Va, Chiplarni qadoqlash uchun, Azot funktsiyasi chiplarni uzoq vaqt davomida saqlash va tashish paytida himoya qilish shart emas.

Ko'proq narsa, Chiplarni qadoqlash mashinasi yuqori samaradorlikdan ustundir, to'g'ri tortish, va chip ishlab chiqarish liniyasi bilan doimiy ravishda ishlash.

Kartoshka chiplari ishlab chiqaruvchi mashina parametrlari

To'liq avtomatik kartoshka chiplari ishlab chiqarish liniyasi DT-PC-500, Imkoniyat uchun 450-500kg / soat.

| Ism | Quvvat iste'moli | Kuchlanish darajasi |

| Bunker bilan lift | 0.75 kvant | 380V 50Hz 3F, sozlash qobiliyati |

| Kartoshka yuvish va peeling mashinasi | 4.75 kvant | 380V 50Hz 3F, sozlash qobiliyati |

| Konveyerni tanlash | 0.75 kvant | 380V 50Hz 3F, sozlash qobiliyati |

| Kartoshka chip to'ng'ichi mashinasi | 1.1 kvant | 380V 50Hz 3F, sozlash qobiliyati |

| Blanching mashinasi | 70 kvant | 380V 50Hz 3F, sozlash qobiliyati |

| Tebranadigan dexonavrate mashinasi | 1.5Kvant | 380V 50Hz 3F, sozlash qobiliyati |

| Havo sovutish chizig'i | 15 kvant | 380V 50Hz 3F, sozlash qobiliyati |

| Qo'rqinlashdan oldin lift konveyeri | 0.75 kvant | 380V 50Hz 3F, sozlash qobiliyati |

| Kartoshka chiplari qovurilgan mashina | 204.5 kvant | 380V 50Hz 3F, sozlash qobiliyati |

| Vibratsiyaning buzilishi mashinasi | 1.5 kvant | 380V 50Hz 3F, sozlash qobiliyati |

| Havo sovutish chizig'i | 8 kvant | 380V 50Hz 3F, sozlash qobiliyati |

| Elevatni ziravor qilish uchun | 0.75 kvant | 380V 50Hz 3F, sozlash qobiliyati |

| Mavsuq mashinasi | 1.5 kvant | 380V 50Hz 3F, sozlash qobiliyati |

| To'liq avtomatik kartoshka chiplarni qadoqlash mashinasi | 6.5Kvant | 380V 50Hz 3F, sozlash qobiliyati |

Kartoshka chiplari liniyasi ishlab chiqaruvchisi

Qo'rqinchli mashina zavodining afzalligi

Oziq-ovqat texnikasi zavodi

30 yillar r&D tarixi

Barqaror mashinasozlik ishi

Vaqtni etkazib berish bo'yicha

Kafolat

12 Oyliklarning sifat kafolati

Butun hayotni texnik qo'llab-quvvatlash va ehtiyot qismlar xizmati

Xizmat

Ishlatgandan so'ng operatsiyadan keyin, parvarishlash.

Zavodda liniya yoki o'chirish bo'yicha bepul mashg'ulotlar

Mijozning zavodida onzit o'rnatish

Umumiy biznes Yangi biznesni rejalashtiruvchini rejalashtirdi.

Xaridor mamlakatiga etkazib berish xizmatlari

Kartoshka chiplari ishlab chiqarish liniyasi narxi

Bizda yuqori saqomlilik uchun ishlab chiqarish liniyasini ommalashtirish uchun professional texnik muhandis jamoasi va mahsulot ishlab chiqish guruhi mavjud, kamroq ishlab chiqarish va undan yaxshiroq foydalanish. Bundan tashqari, Biz mijozlarga o'z biznesining to'g'ri echimini tushunamiz va tezda javob beramiz.

Siz hozir bizning jamoamiz bilan bog'lanish va iqtiboslash uchun jamoamiz bilan bog'lanishingiz mumkin.

Tegishli mashinalar

Fransuz Fres ishlab chiqarish liniyasi, banan chiplari ishlab chiqarish liniyasi, pentaplar qovurilgan chiziq. uzluksiz qovurdoq, Kichik kattalik kartoshka chiplari ishlab chiqarish liniyasi