Дүүргэлтийн алдагдал нь хүнсний үйлдвэрүүдэд тулгардаг хамгийн түгээмэл үйлдвэрлэлийн асуудлуудын нэг юм Автомат багцын автомат дугуй. Та жижиг худалдааны гал тогоо эсвэл том хэмжээний үйлдвэрлэлийн шугам ажиллуулдаг, дүүргэх дусал, хэт дүүргэх, хажуугийн гоожих, эсвэл боодол хугарах нь ноцтой асуудал үүсгэж болзошгүй: бүтээгдэхүүний хаягдал, царай муутай, газрын тосны бохирдол, үр ашиг багассан.

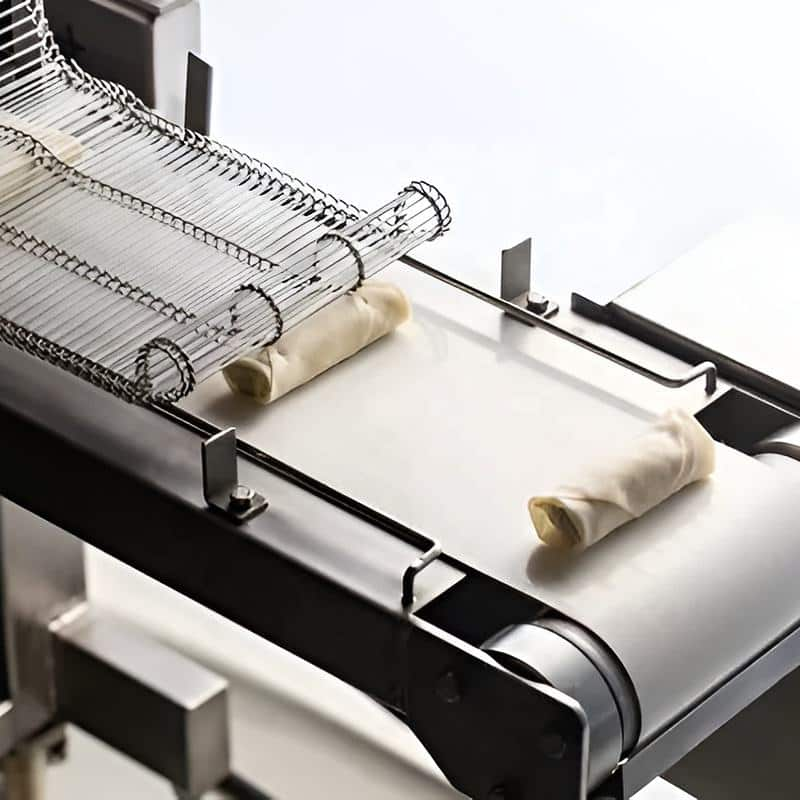

Энэ бол а цогц, алхам алхмаар шийдэл дүүргэлтийн алдагдлыг оношлох, засахад тань туслах болно Хаврын ролл хийх машинууд, үндсэн шалтгааныг ойлгох, мөн урьдчилан сэргийлэх засвар үйлчилгээ хийнэ. Пүршний машин үйлдвэрлэгчийн хувьд, Шийдвэрийг хангахын тулд бид бодит үйлдвэрийн тохиолдлыг нэгтгэн дүгнэдэг практик, үр дүнтэй, мөн хэрэглэхэд хялбар.

1. Хаврын өнхрөх машин дахь дүүргэлтийн нэвчилтийн төрлийг ойлгох

Асуудлыг шийдэхийн өмнө, та тодорхойлох ёстой ямар төрлийн алдагдал болж байна. Янз бүрийн гэмтэл нь янз бүрийн механик эсвэл үйл ажиллагааны асуудлаас үүсдэг.

1.1 Хооллох хошуунаас гоожиж байна

- Боохоос өмнө дуслаар дүүргэх

- Боодлыг битүүмжлэсний дараа дүүргэлт үргэлжилнэ

- Цорго зөв хаагдахгүй байна

Холбогдох боломжтой тоног төхөөрөмж: дүүргэх насос, пневматик хавхлага, эргэдэг хавхлага.

1.2 Боодолын талаас гоожиж байна

- Бөглөх нь өнхрөхөөс өмнө шахаж гаргадаг

- Боодол нь нягт битүүмжлэх боломжгүй

- Боодол нь өнхрөх явцад хагардаг

1.3 Хайруулын болон хөлдөөх үед гоожих

- Бүтээгдэхүүнийг аль хэдийн хэлбэржүүлсний дараа дүүргэх нь гадагшилдаг

- Бүрэн битүүмжлэлгүй эсвэл усархаг дүүргэлтийн шинж тэмдэг

Нэвчилтийн төрлийг тодорхойлох замаар, алдааг олж засварлах нь илүү хялбар болно.

2. Пүршний өнхрөх машинууд дахь дүүргэлтийн алдагдлын гол шалтгаанууд

2.1 Хэт нойтон эсвэл хэт зөөлөн дүүргэлт

Хаврын өнхрөх дүүргэлт нь өөр өөр байдаг (ногооны, мах, шилний галбар), гэхдээ өндөр чийгшилтэй үргэлж гоожих шалтгаан болдог.

Шинж тэмдэг

- Бөглөх нь устай юм шиг санагддаг

- Бункер дэх шингэний усан сан

- Боодол нь өнхрөх явцад амархан урагддаг

Үндсэн шалтгаанууд

- Хүнсний ногоо хатаагүй байна

- Эмульсжүүлээгүй махны хольц

- Буруу холбогч харьцаа

2.2 Тэгш бус эсвэл хэт их дүүргэх хэмжээ

Арилжааны пүршний машинууд нь нарийн дүүргэлтэнд тулгуурладаг.

Хэрэв дүүргэх насосыг тохируулаагүй бол, гоожих нь зайлшгүй болдог.

Шалтгаанууд орно:

- Буруу дүүргэх эзэлхүүний параметр

- Гэмтсэн дүүргэх насосны битүүмжлэл

- Пневматик насос дахь агаарын даралтын тэнцвэргүй байдал

2.3 Боодлын чанарын асуудал

Төгс дүүргэсэн ч гэсэн, чанар муутай боодол гоожих шалтгаан болдог.

Ердийн асуудлууд

- Боодол нь хэтэрхий нимгэн

- Боодол нь хэт хуурай/хатуу

- Зуурмагийн томъёо буруу

- Боодол нь жигд чанаж болохгүй Хаврын өнхрөх боолт

2.4 Машин доторх механик асуудлууд

Ихэвчлэн гоожиж буй машинууд орно:

- Шахуургын цилиндрийг дүүргэх

- Пневматик ороомог хавхлага

- Эргэдэг хавхлага

- Скрепер буюу дарах бул

- Өнхрөх, нугалах механизм

Аливаа жижиг буруу тохируулга нь боодолыг эвдэж эсвэл халихад хүргэж болзошгүй.

2.5 Машины буруу тохиргоо

Буруу параметрүүд нь ихэвчлэн гоожиход хүргэдэг:

- Дүүргэх температур хэт өндөр байна

- Боох хурд хэт хурдан байна

- Даралтын тохиргоо буруу байна

- Цоргоны байрлал буруу тохируулагдсан

- Өнхрөх битүүмжлэл нь хэтэрхий сул эсвэл хэтэрхий хатуу

2.6 Өдөр тутмын засвар үйлчилгээ муу

Нийтлэг алдаа:

- Цорго зөв цэвэрлээгүй

- Бөглөх гарцыг хааж буй үлдэгдэл

- Битүүмжлэх резинэн элэгдэл

- Тосолгооны дутагдал

3. Дүүргэлтийн алдагдлыг арилгах алхам алхмаар шийдлүүд

Үйлдвэрийн бодит алдааг олж засварлахад суурилсан нарийвчилсан шийдлүүдийг доор харуулав.

3.1 Эхлээд дүүргэх томъёог засна уу (Хамгийн чухал)

3.1.1 Чийгийг багасгах

- Хүнсний ногоог огтолсны дараа хатаана

- Хүнсний ногоог цайруулж, ус шахаж ав

- Чийгийг түгжихийн тулд тос нэмнэ

- Махны ломбоны цардуул/биндэрийг нэмэгдүүлнэ

Санал болгож буй чийгийн түвшин:

≤ 15% хүнсний ногооны булгийн хувьд

≤ 20% махны хувьд + хүнсний ногооны холимог

3.1.2 Байгалийн биндэр нэмнэ

Нийтлэг хүнсний зориулалттай холбогч бодис:

- Эрдэнэ Кроуз

- Төмсний цардуул

- Tapioca цардуул

- Гурилын зутан

- Би уураг

Цардуул бага зэрэг нэмэгдэх нь дүүргэлтийн тогтвортой байдлыг ихээхэн сайжруулдаг.

3.1.3 Дүүргэлтийн температурыг хянах

Хэт халуун бол → усархаг болно

Хэт хүйтэн бол → хатуурч, цорго бөглөрнө

Хамгийн сайн дүүргэх температур: 10°C - 20 °C машин дүүргэх зориулалттай.

3.2 Дүүргэлтийн хэмжээ ба даралтыг тохируулна уу

3.2.1 Дүүргэх насосыг тохируулах

- Дүүргэлтийн хэмжээг 5-10% бууруулах

- Поршений цохилтыг тохируулна уу

- Тогтвортой агаарын даралтыг тохируулах (0.4-0.6 МПа)

3.2.2 Элэгдсэн лацыг солих

Хэт их ашигласан битүүмжлэл нь тогтмол бус даралт → гоожих шалтгаан болдог.

Чек:

- O-цагираг

- Поршений битүүмжлэл

- Шахуургын резинэн жийргэвч

Бүр солих 3-6 сар хүнд үйлдвэрлэлийн зориулалттай.

3.3 Боодлын чанарыг сайжруулах

3.3.1 Боодлын зузааныг тохируулна уу

Стандарт боодлын зузаан:

0.4 мм - 0.6 мм

Хэт нимгэн → урагдах

Хэт зузаан → чанга өнхрөх боломжгүй

3.3.2 Боодлын хуурайшилтыг засах

Хэрэв боодол хэтэрхий хурдан хатаж байвал:

- Ус шүршигч нэмнэ

- Конвейерийн температурыг багасгах

- Зуурмагийн харьцааг тохируулна уу

3.3.3 Зуурсан гурилын харьцааг сайжруулах (Боодолтой машинуудын хувьд)

Зуурмагийн үндсэн томъёо:

- Гурил

- Ус

- Давс

- Газрын тос

Хэрэв хагарал үүссэн бол:Бат бөх чанарыг нэмэгдүүлэхийн тулд цардуул эсвэл уургийн агууламжийг 1-3% -иар нэмэгдүүлнэ.

3.4 Хаврын өнхрөх машин дахь механик асуудлыг засах

3.4.1 Цоргоны тэгш байдлыг шалгана уу

Буруу тохируулсан хушуу нь дүүргэгчийг төвөөс гадагшлуулахад хүргэдэг.

Тааруулах:

- Цоргоны өнцөг

- Цоргоны өндөр

- Боодолтой хооллох цэгээс зай

3.4.2 Цэвэр & Дүүргэлтийн системийг тослох

Алхам:

- Дүүргэх насосыг зайлуул

- Дотоод танхимыг цэвэрлэ

- Газрын тос тосолгооны цэгүүд

- Хэрэглэх 100% хүнсний зориулалттай тос

3.4.3 Rolling-ийг тохируулна уу & Эвхэх механизм

Хэрэв өнхрөх нь сул байвал → дүүргэлт гоожиж байна

Хэрэв өнхрөх нь нягт байвал → боодол нь хугарна

Эд юмны цүглуулга:

- Уналтуулмал

- Эвхэх гарны хурд

- Хавчих нягт

3.5 Машины параметрүүдийг оновчтой болгох

Аж үйлдвэрийн пүршний машинд санал болгож буй суурь үзүүлэлт:

| Зөнийн тавь чанар | Санал болгож буй үнэ цэнэ |

|---|---|

| Өнхрөх хурд | 50-100 ширхэг/мин (Загвараас хамаарна) |

| Буурийн зузаан зэрэг | 0.45 мм |

| Дүүргэлтийн хэмжээ | 12Нэг ширхэг - 20 гр |

| Цоргоны температур | Өрөөний температур |

| Агаарын даралт | 0.45-0.55 МПа |

| Роллерийн даралт | Дунд (хэт дарахаас зайлсхий) |

Бүтээгдэхүүнийхээ хэмжээнээс хамаарч нарийн тааруулна уу.

4. Ирээдүйд гоожихоос сэргийлэхийн тулд урьдчилан сэргийлэх засвар үйлчилгээ

4.1 Өдөр тутмын засвар үйлчилгээний хяналтын хуудас

- Унтраахаасаа өмнө дүүргэх насосыг цэвэрлэ

- Цорго халуун усаар зайлж угаана

- Боодол нь урагдах хурдыг шалгана уу

- Агаарын даралт, тосны түвшинг шалгана уу

- Конвейерийн хурдыг шалгах

4.2 Долоо хоногийн засвар үйлчилгээ

- O-цагирагуудыг шалгана уу

- Туршилтын даралтын насос

- Эргэдэг хавхлагыг цэвэрлэ

- Эвхэх систем дээр боолтыг чангална

4.3 Сарын засвар үйлчилгээ

- Лацыг солих

- Цилиндрийн жигд байдлыг шалгана уу

- Цорго суурилуулах хавтанг тохируулна уу

- Туршилтын машин тохируулга

Эдгээр алхмууд нь гэнэтийн дүүргэлтийн алдагдлыг эрс багасгадаг.

5. Хэзээ эд ангиудыг солих вэ? (Маш чухал)

Дараахь тохиолдолд солино уу:

- Дүүргэх насос нь даралтын алдагдлыг харуулж байна

- Эргэдэг хавхлага жигд эргэдэггүй

- Цорго дахин дахин бөглөрдөг

- Wrapper cracking rate > 5%

- Машины чичиргээ нэмэгддэг

Элэгдсэн эд ангиудыг ашиглах нь алдагдлыг эрс нэмэгдүүлдэг.

6. Түгээмэл асуултууд (FAQ)

Q1: Хайруулын үеэр хаврын булцуу яагаад гоождог вэ??

Учир нь боодол нь зөв битүүмжлэгдээгүй эсвэл дүүргэгч нь хэт их чийгтэй байдаг.

Q2: Яагаад дүүргэгч нь боодол ирэхээс өмнө унадаг вэ??

Цорго гоожиж байна - битүүмжлэл хуучирсан эсвэл хэт өндөр даралт тохируулсантай холбоотой байж магадгүй.

Q3: Яагаад хүнсний ногооны дүүргэлт илүү их гоождог вэ??

Хүнсний ногоо нь их хэмжээний эслэг агуулдаг боловч халах үед ус ялгаруулдаг.

Q4: Машины буруу хурд нь гоожиж болзошгүй?

Мон. Хэрэв боох хурд хэт хурдан байвал, өнхрөх нь бүрэн битүүмжлэхгүй.

7. Spring Roll машин үйлдвэрлэгчийн мэргэжлийн зөвлөгөө

Дээрх алхмуудыг хийсний дараа гоожсон хэвээр байвал, асуудал шаардаж магадгүй мэргэжлийн машин тохируулга эсвэл эд анги солих.

DT Хүнсний машин найдвартай пүршний өнхрөх машин үйлдвэрлэгч, хангах:

- Автомат пүршний ороомог үйлдвэрлэх шугам

- Пүршний ороох машин

- Дүүргэх насосны систем

- Өнхрөх & эвхдэг тоног төхөөрөмж

- Төрөл бүрийн дүүргэлтэнд тохируулга хийх

- Газар дээр нь суурилуулах & техникийн зааварчилгаа

Манай машинууд Зүүн өмнөд Азид өргөн хэрэглэгддэг, Европ, Ойрхи Дорнод, болон Өмнөд Америк.

Бид танд тусалж чадна:

- Нэвчилттэй холбоотой асуудлыг оношлох

- Дүүргэлтийн тогтвортой байдлыг сайжруулах

- Боох механизмыг тохируулах

- Хүнсний ногоо/мах/шилэн гоймонгийн дүүргэлтийг дүүргэх системийг тохируулах

Бидэнтэй холбоо барина уу

Хаврын өнхрөх машин дахь дүүргэлтийн алдагдлыг шийдвэрлэхийн тулд хослуулах шаардлагатай:

- Зөв бөглөх томъёо

- Машины зөв тохиргоо

- Боодлын чанарын хяналт

- Тогтмол засвар үйлчилгээ

Дээрх алхам алхмаар аргуудыг хэрэглэснээр, үйлдвэрүүд чадна бүтээгдэхүүний хаягдлыг мэдэгдэхүйц бууруулах, үйлдвэрлэлийн үр ашгийг дээшлүүлэх, мөн том хэмжээний захиалгад чанарыг тогтвортой байлгах.

Хэрэв та мэргэжилтний тусламж авахыг хүсч байвал эсвэл сайжруулалт хэрэгтэй бол Автомат багцын автомат дугуй, Бидэнтэй холбоо барина уу - манай техникийн баг гоожсон асуудлыг хурдан бөгөөд мэргэжлийн түвшинд шийдвэрлэхэд тань туслах болно.