1. Introduction to Beef Jerky and the Role of Machines

industrial beef jerky machine :Beef jerky has a history that dates back thousands of years, from Native American pemmican to modern, flavor-packed snacks sold worldwide. Hari ini, the market has evolved from traditional sun-drying to fully automated jerky production lines that ensure high efficiency, consistent taste, and compliance with food safety regulations.

For commercial producers, the question “What machine is used for beef jerky?” is not about a single device—it’s about an integrated system of machines working together.

According to Market Research Future, the global jerky market is projected to grow at over 6% CAGR dari 2024 ke 2030, driven by consumer demand for high-protein, low-carb snacks. This means more meat processors are investing in industrial beef jerky machine.

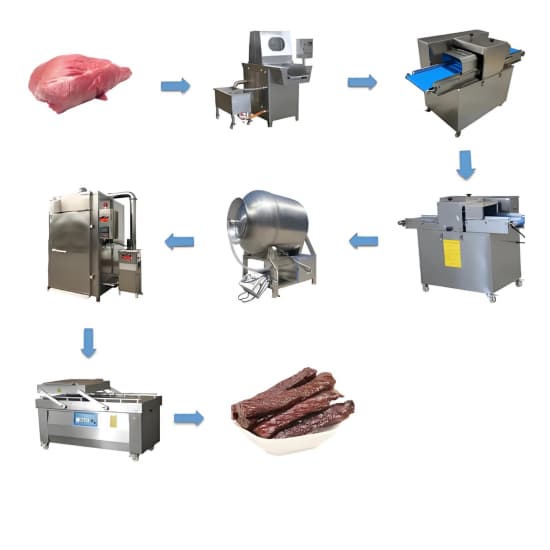

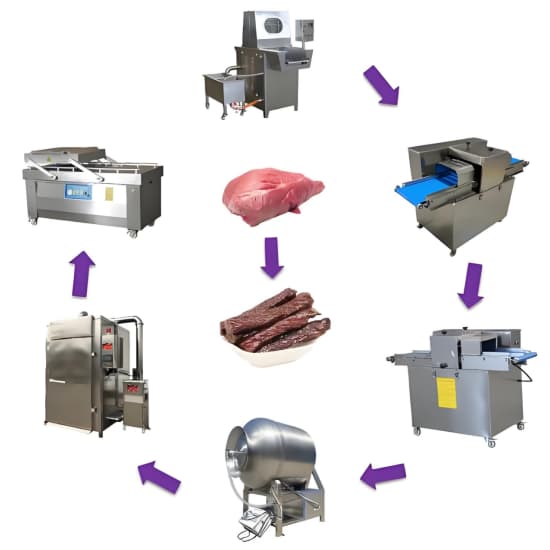

2. The Complete Beef Jerky Production Process

Let’s break down the process and see what machines are used at each stage.

Melangkah 1: Meat Preparation & Trimming

Sebelum mengiris, fresh beef must be inspected, trimmed, and sometimes frozen slightly to make cutting easier. This stage ensures:

- Removal of excess fat

- Consistent meat quality

- Compliance with hygiene standards

Mesin Opsional:

- Meat Trimming Table with Conveyor – speeds up manual trimming and waste removal.

Melangkah 2: Meat Slicing Machine

Fungsi: Cuts meat into uniform slices or strips for even drying.

Working Principle:

A rotating blade atau guillotine-style cutter slices beef to preset thickness. In high-capacity models, conveyor belts feed meat automatically to maximize throughput.

Structure Components:

- Bodi baja tahan karat (kelas makanan 304/316)

- Cutting blade assembly

- Thickness adjustment system

- Penjaga keamanan

- Conveyor feeding system (in automatic models)

Technical Table – Meat Slicing Machine:

| Model | Kekuatan (kW) | Kapasitas (kg/jam) | Ketebalan Irisan | Ukuran (mm) | Berat (kg) |

|---|---|---|---|---|---|

| MS-200 | 0.75 | 200 | 2–10mm | 650×500×850 | 80 |

| MS-500 | 1.5 | 500 | 1–15 mm | 950×700×1100 | 150 |

| MS-1000 | 3.0 | 1000 | 1–20 mm | 1500×1200×1500 | 320 |

Keuntungan:

- Uniform thickness = consistent drying time

- Adjustable for different products (jerky, biltong, pork strips)

- Penghematan biaya tenaga kerja

Melangkah 3: Meat Marinating Machine (Vacuum Tumbler)

Fungsi: Infuses seasoning into meat using vacuum pressure and tumbling motion.

Cara Kerjanya:

- Meat slices and marinade are loaded into the drum.

- Air is removed to create vacuum.

- Drum rotates, causing meat to massage against itself and absorb seasoning quickly.

Technical Table – Vacuum Marinating Machine:

| Model | Kapasitas (L) | Kekuatan (kW) | Kecepatan (rpm) | Ukuran (mm) | Berat (kg) |

|---|---|---|---|---|---|

| VT-300 | 300 | 1.1 | 6–8 | 1500×850×1100 | 260 |

| VT-800 | 800 | 2.2 | 6–8 | 2100×1200×1600 | 520 |

| VT-1500 | 1500 | 4.0 | 6–8 | 2600×1600×1800 | 850 |

Keuntungan:

- Shorter marination time (30–60 minutes vs 8–12 hours manually)

- Even seasoning distribution

- Better texture and tenderness

Melangkah 4: Beef Jerky Drying Machine

Tujuan: Removes moisture while preserving flavor and nutrients.

Drying Methods:

- Hot Air Circulation Dryer – Economical, widely used.

- Heat Pump Dryer – Energy-efficient, kontrol suhu yang tepat.

- Continuous Conveyor Dryer – High capacity, suitable for large plants.

Technical Table – Beef Jerky Dryer:

| Model | Trays | Kekuatan (kW) | Temp Range | Kapasitas (kg/batch) | Ukuran (mm) |

|---|---|---|---|---|---|

| DR-24 | 24 | 9 | 40–90 ° C. | 100–120 | 1400×1200×2000 |

| DR-48 | 48 | 15 | 40–90 ° C. | 200–250 | 1800×1600×2200 |

| DR-96 | 96 | 22 | 40–90 ° C. | 400–500 | 3200×2000×2300 |

Melangkah 5: Smoking Oven (Opsional)

If smoked flavor is desired, A smoke oven can be used before or during drying.

Fitur:

- Smoke generator with wood chips

- Temperature and humidity control

- Batch or continuous operation

Melangkah 6: Konveyor pendingin

Tujuan: Brings jerky to a safe packaging temperature quickly to prevent bacteria growth.

Melangkah 7: Mesin pengemasan

Jenis:

- Vacuum Packaging Machine – Removes air to extend shelf life.

- Nitrogen Flushing Machine – Prevents oxidation, keeps jerky fresh.

Technical Table – Vacuum Packaging Machine:

| Model | Seal Width | Kekuatan (kW) | Kecepatan (packs/min) | Ukuran (mm) |

|---|---|---|---|---|

| VP-400 | 400 mm | 1.5 | 5–8 | 1000×600×900 |

| VP-600 | 600 mm | 2.2 | 6–10 | 1300×800×950 |

| VP-1000 | 1000 mm | 3.5 | 10–15 | 1800×1100×1200 |

3. Global Market Trends for Beef Jerky

- Amerika Utara: Largest consumer market, prefers automated, high-capacity lines.

- Asia-Pasifik: Growing middle class, high demand for flavored jerky.

- Eropa: Strong food safety regulations, demand for CE-certified machines.

4. Investment Cost Case Studies

- Small Workshop (500 kg/day) – $20,000–$50,000

- Medium Factory (1–3 tons/day) – $80,000–$150,000

- Large Industrial Plant (5–10 tons/day) - - $200,000+

5. Pemeliharaan & Kebersihan

- Clean all contact surfaces daily.

- Check lubrication points weekly.

- Replace worn belts or seals.

- Use stainless steel parts to prevent rust.

6. Bagaimana memilih mesin yang tepat

- Volume produksi

- Ketersediaan ruang

- Anggaran

- Local power supply (voltase, fase)

- Certification requirements (Ce, Ul, Iso, Haccp)

7. Extended FAQ for industrial beef jerky machine

- Can these machines process pork or chicken jerky? – Yes.

- How long is the machine warranty? – Typically 12–24 months.

- Do you provide installation service? – Yes, di tempat atau jarak jauh.

- Can I customize machine size? – Yes, OEM is available.

- What’s the average drying time? – 6–12 hours depending on thickness.

- Can I use solar energy for drying? – Yes, for small-scale production.

- How much electricity does a dryer use? – 9–25 kW depending on model.

- Is vacuum marination necessary? – Recommended for consistency.

- Do I need a metal detector? – Yes, for food safety compliance.

- How soon can I start production after machine delivery? – Usually within 1–2 weeks after installation.

8. RFQ – Get Your Beef Jerky Production Line Quote

If you are ready to start or upgrade your beef jerky production and industrial beef jerky machine, kita Mesin Makanan DT Co., Ltd. team can provide:

- Full production line design

- Custom capacity options

- Harga kompetitif

- CE/ISO-certified machines