A Practical Guide to French-Standard Automatic Spring Roll Production Equipment

1. Why France Is a Strategic Market for Spring Roll Machines

France is one of Europe’s largest consumers of Asian convenience foods, including spring rolls (nems). From frozen food factories to catering suppliers, demand continues to grow due to:

- Strong Vietnamese and Asian diaspora

- High penetration of frozen and ready-to-cook foods

- Mature cold-chain logistics

- Strict but transparent food machinery regulations

For machinery exporters, France is not a low-entry market, but once compliance is achieved, it offers long-term stability, premium pricing, and repeat orders.

2. Understanding the French Definition of a “Compliant” Spring Roll Machine

In France, a spring roll making machine is not evaluated only on productivity. It is assessed as a food-contact industrial system, subject to EU and national regulations.

A compliant machine must simultaneously satisfy:

- Food safety laws

- Electrical and mechanical safety

- Hygiene design principles

- Environmental and energy regulations

French buyers do not ask “How fast is the machine?” first.

They ask “Is this machine legal and auditable in France?”

3. Core EU & French Standards for Spring Roll Machines

3.1 CE Marking (Mandatory)

Any spring roll making machine exported to France must carry sertifikasi CE, covering:

- Machinery Directive 2006/42/EC

- Low Voltage Directive (LVD)

- Electromagnetic Compatibility (EMC)

CE is not a sticker. It is a technical conformity system termasuk:

- Risk assessment

- Technical file

- Declaration of Conformity

3.2 Food Contact Materials Regulation

All parts touching:

- Rice paper

- Fillings

- Oil or moisture

Must comply with:

- EC 1935/2004

- EU 10/2011 (for plastics, jika berlaku)

This typically requires:

- Baja tahan karat SUS304 atau SUS316

- FDA or EU food-grade belts

- No galvanized or painted food-contact surfaces

3.3 French Hygiene Expectations (Higher Than Average EU)

French inspectors are known for strict interpretation of hygiene design, termasuk:

- Smooth welds (no dead corners)

- Easy dismantling without tools

- Full wash-down compatibility

- No exposed threads near food zones

A machine that passes in other EU countries may still be rejected in France if hygiene details are overlooked.

4. What “French-Standard” Spring Roll Production Actually Means

French spring roll producers typically manufacture nems, which differ from other markets.

Key product characteristics:

- Thin rice paper

- High moisture fillings

- Tight rolling structure

- Panjang dan diameter seragam

- High freezing stability

Karena itu, a spring roll making machine for France must deliver precision and consistency, not just speed.

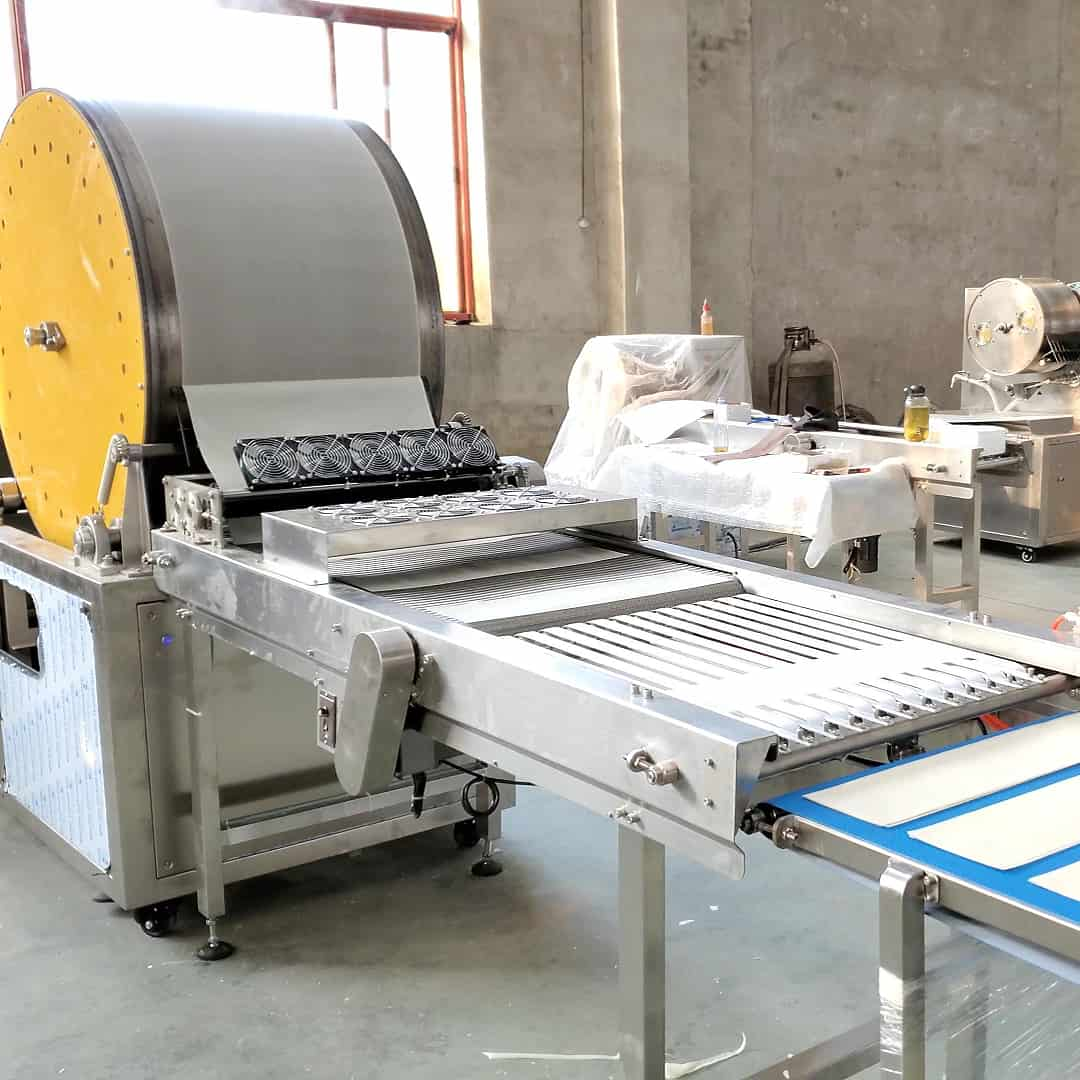

5. Functional Breakdown of a French-Standard Spring Roll Machine

Instead of listing parameters, this section explains how French buyers evaluate each module.

5.1 Rice Paper Feeding System

French processors prefer:

- Continuous rice paper sheet feeding

- Automatic tension control

- Moisture-stabilized paper handling

Critical requirements:

- No tearing

- No paper shrinkage

- Stable feeding at low speeds

Machines designed for thick wheat wrappers often fail here.

5.2 Filling Portioning System

Portion accuracy is a legal and commercial issue in France.

Requirements:

- Weight deviation ≤ ±2%

- Consistent filling distribution

- No leakage during rolling

Most French buyers demand:

- Servo-controlled filling

- Multi-ingredient compatibility

- Easy cleaning between recipes

5.3 Rolling and Folding Mechanism

For nems, folding must be:

- Tight

- Symmetrical

- Without air pockets

French manufacturers often test machines by freezing and frying products repeatedly to evaluate structural stability.

5.4 Cutting and Length Control

Standard French nem sizes:

- 90–110 mm length

- Uniform edge sealing

Machines must offer:

- Adjustable cutting length

- Membersihkan, non-frayed edges

- Minimal rice paper cracking

6. Automation Level Preferred by French Buyers

French factories typically fall into mid-to-high automation, not ultra-low-cost systems.

Preferred configuration:

- Automatic forming

- Semi-automatic loading

- Manual quality inspection stations

Why?

- Labor cost is high

- Product quality must remain flexible

- Full automation is often unnecessary

7. Typical Technical Parameters (Market-Realistic)

Rather than idealized specs, below is what French buyers actually accept:

- Kapasitas: 2,000–6,000 pcs/hour

- Catu daya: 380V / 50Hz / 3 fase

- Sistem Kontrol: Plc + touch screen (French language preferred)

- Bahan: Sus304 (minimum)

- Noise level: <75 dB

Overpromising higher outputs often reduces credibility.

8. Electrical Standards for Spring Roll Machines in France

Electrical compliance is non-negotiable.

Key points:

- Schneider / Siemens components preferred

- Full grounding system

- Emergency stop buttons at multiple points

- Lockable electrical cabinet

Machines with unknown electrical brands face immediate rejection.

9. Documentation Required by French Importers

A spring roll making machine shipped to France must be accompanied by:

- CE Declaration of Conformity

- Skema kelistrikan

- Mechanical drawings

- User manual (French language strongly preferred)

- Maintenance instructions

- Daftar suku cadang

Incomplete documentation is a common cause of customs delays.

10. Instalasi & Commissioning Expectations in France

French clients increasingly request:

- Dukungan commissioning jarak jauh

- Video-guided installation

- On-site technician option (preferred but not mandatory)

They expect:

- Clear installation drawings

- Defined responsibility boundaries

- Commissioning checklist

11. Layanan purna jual: A Deciding Factor in France

In France, after-sales service outweighs machine price.

Buyers evaluate:

- Response time

- Ketersediaan suku cadang

- Technical English or French support

- Clear warranty terms

Suppliers without structured after-sales systems rarely secure repeat orders.

12. Common Mistakes When Exporting Spring Roll Machines to France

- Assuming CE is optional

- Using non-food-grade conveyor belts

- Ignoring French hygiene expectations

- Overstating production capacity

- Providing English-only manuals

- No spare parts strategy

These mistakes are often irreversible at the negotiation stage.

13. Logistik & Packaging for France

French importers prefer:

- ISPM 15 compliant wooden crates

- Shock protection for electrical cabinets

- Moisture-proof wrapping

Machines damaged during transport often result in full claim disputes, regardless of fault.

14. Who Buys Spring Roll Machines in France?

Primary buyer profiles:

- Produsen makanan beku

- Asian food processing factories

- Catering ingredient suppliers

- OEM food brands

Each profile values different machine features, Tetapi compliance is universal.

15. Long-Term Market Outlook in France

Demand drivers:

- Growth of frozen ready meals

- Expansion of Asian cuisine

- Retail private-label products

Trend direction:

- Medium-capacity machines

- Higher hygiene standards

- Lower labor dependency

Suppliers aligned with these trends gain long-term market access.

16. Final Considerations Before Supplying to France

A spring roll making machine exported to France must be viewed as:

A regulated food-processing system, not a simple forming machine.

Success in France depends on:

- Kepatuhan

- Transparency

- Technical credibility

- Long-term service commitment

Suppliers who adapt to French standards do not just enter France —

they unlock the entire EU market.