1. Perkenalan: Apa itu Lini Produksi Mie Instan dengan Mesin Pengemas ?

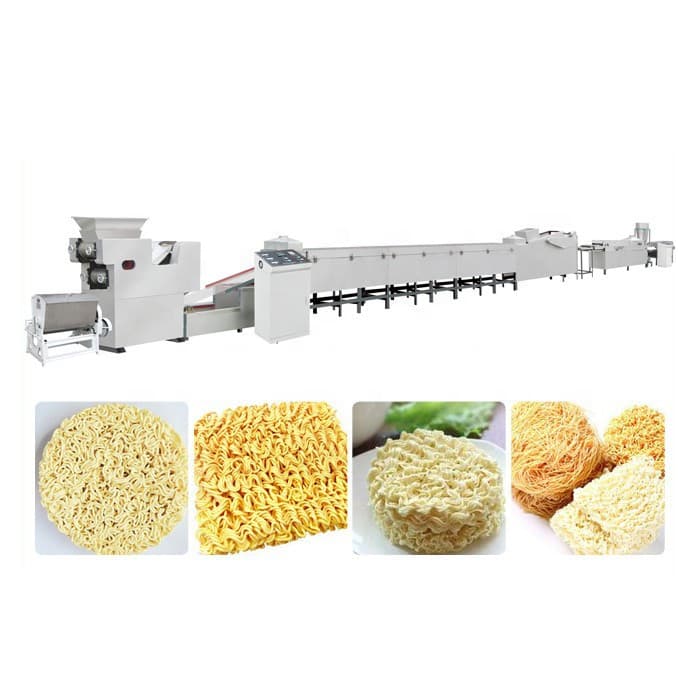

Sebuah Jalur produksi mie instan dengan Mesin Pengemas adalah sepenuhnya otomatis, sistem skala industri yang dirancang untuk berproduksi, memasak, kering, dan mengemas mie instan secara efisien dan higienis. Lini produksi ini penting bagi produsen yang ingin memenuhi permintaan global yang terus meningkat sambil menjaga konsistensi produk, keamanan, dan stabilitas rak.

Baris lengkap ini mencakup tahapan pencampuran adonan, mengepul, pemotongan dan pembentukan mie, menggoreng atau mengeringkan udara, pendinginan, dan pengemasan otomatis terintegrasi.

2. Permintaan Global dan Tren Pasar

Pasar mie instan telah mengalami pertumbuhan eksponensial di seluruh Asia, Afrika, Amerika Latin, dan Eropa Timur. Menurut Asosiasi Mie Instan Dunia (LAIN), lebih dari 120 miliar porsi dikonsumsi secara global setiap tahunnya.

Tren Utama:

- Pertumbuhan di mie cangkir Dan mie yang tidak digoreng

- Meningkatnya permintaan untuk pengemasan otomatis

- Ekspansi ke mie yang lebih sehat dan bebas gluten

- Integrasi dengan Kontrol kualitas berbasis AI

3. Jenis Mie Instan

Lini produksi Anda dapat disesuaikan untuk memproduksi berbagai jenis mie:

- Mie instan goreng (paling umum)

- Mie dikukus dan dikeringkan di udara (pilihan yang lebih sehat)

- Mie cangkir (dikemas sebelumnya dalam mangkuk atau cangkir)

- Mie dalam kantong (blok longgar dalam foil/kertas/plastik)

Setiap jenis mie memerlukan sedikit perubahan pada komponen pengolahan dan pengemasannya.

4. Gambaran Umum Proses Produksi

Alur kerja produksi mie instan biasanya mengikuti langkah-langkah berikut:

- Mencampur bahan (tepung, air, garam, aditif)

- Terpal adonan dan peracikan

- Mengukus lembaran mie

- Memotong dan membentuk untaian mie

- Menggoreng atau mengeringkan

- Pendinginan dan penyelarasan

- Ditimbang dan dikemas dengan bumbu sachet

- Penyegelan dan pelabelan

- Tinju karton dan pembuatan palet

5. Komponen Inti Lini Produksi Mie Instan

| Nama Komponen | Fungsi |

|---|---|

| Pengaduk Adonan | Membentuk adonan seragam dari bahan-bahan |

| Rol Majemuk | Lembaran dan padatkan adonan |

| Konveyor Mengukus | Kukus mie hingga matang setengahnya |

| Perangkat Pemotong | Memotong mie menjadi untaian halus |

| Penggorengan atau Pengering | Menghilangkan kelembapan, meningkatkan umur simpan |

| Konveyor pendingin | Menurunkan suhu sebelum pengepakan |

| Pengumpan Bumbu | Mengeluarkan sachet bumbu |

| Mesin pengemasan otomatis | Membungkus dan menyegel mie |

| Detektor Logam | Memastikan kepatuhan keamanan pangan |

| Pengkodean & Sistem Pelabelan | Mencetak nomor kedaluwarsa dan nomor batch |

6. Perincian Terperinci: Dari Adonan hingga Pengemasan Akhir

6.1 Persiapan dan Pencampuran Adonan

Mixer vakum berkecepatan tinggi menggabungkan tepung terigu, air alkali, dan nutrisi opsional di bawah tekanan terkendali, membentuk adonan elastis.

6.2 Terpal dan Bergulir

Beberapa rol memampatkan adonan menjadi lembaran dengan ketebalan yang dapat disesuaikan.

6.3 Bagian Mengukus

Mengukus membuat pati menjadi gelatin, membentuk tekstur mie yang diinginkan. Suhu ~100°C.

6.4 Memotong dan Mengeriting

Lembaran yang dikukus dipotong menjadi untaian dan digulung menjadi bentuk bergelombang yang khas menggunakan pisau putar.

6.5 Penggorengan atau Pengeringan Udara Panas

Goreng dengan minyak sawit pada suhu ~150–160°C selama 90–120 detik, atau dikeringkan di udara untuk produk yang sadar kesehatan.

6.6 Zona Pendinginan

Berpendingin udara hingga suhu sekitar untuk menghindari kondensasi dalam kemasan tertutup.

6.7 Penimbangan dan Penyisipan Sachet

Setiap blok mie dipadukan dengan bubuk perasa, bungkus minyak, atau sayuran dehidrasi.

6.8 Sistem Pengemasan Otomatis

Mie dan sachet dikemas dalam cangkir atau dibungkus menggunakan FFS horizontal atau vertikal tingkat lanjut (segel pengisian formulir) sistem.

7. Jenis Mesin Pengemas Mie Instan

7.1 Mesin Pembungkus Aliran Horizontal

- Ideal untuk kemasan plastik jenis bantal

- Kecepatan: 100–300 bungkus/menit

7.2 Mesin Pengemas Mie Gelas/Mangkuk

- Menangani wadah dengan penutup

- Terintegrasi dengan penyegelan dan pelabelan

7.3 Mesin FFS Vertikal

- Cocok untuk bumbu sachet

- Bentuk tas, mengisi, dan menyegel secara otomatis

7.4 Mesin Karton dan Bundling

- Kelompok mengemas ke dalam kotak ritel

- Opsi pembungkus susut tersedia

8. Pertimbangan Bahan Kemasan dan Umur Simpan

| Jenis Bahan | Keterangan | Manfaat |

|---|---|---|

| Film BOPP/PP | Umum untuk mie kantong | Biaya rendah, penghalang kelembaban |

| Piala Kertas + Tutup Foil | Digunakan untuk mie cup | Aman untuk microwave, dapat ditumpuk |

| Kantong Multi-lapis | Untuk paket bumbu | Penghalang tinggi, menjaga aroma |

Umur simpan biasanya berkisar dari 6 bulan sampai 12 bulan, tergantung pada kandungan minyak dan bahan kemasan.

9. Spesifikasi Teknis Lini Produksi

Tabel berikut menyajikan secara rinci spesifikasi teknis untuk rata-rata lini produksi mie instan skala industri dengan mesin pengemas:

| Spesifikasi | Nilai/Rentang |

|---|---|

| Kapasitas produksi | 30,000 - - 300,000 bungkus/hari |

| Kecepatan Keluaran | 80–300 kue mie/menit |

| Volume Pencampuran Adonan | 50–500kg/batang |

| Suhu Mengukus | 98–105°C |

| Suhu Minyak Goreng (Mie goreng) | 150–165°C |

| Suhu Pengeringan (Mie yang tidak digoreng) | 75–95°C |

| Kecepatan Mesin Pengemasan | 80–200 bungkus/menit |

| Catu daya | 380V / 50Hz / 3 Fase |

| Konsumsi Daya Total | 100–250kW (tergantung pada skala) |

| Bahan mesin | Stainless steel grade makanan Sus304 |

| Tekanan udara (untuk kemasan) | 0.6–0,8 MPa |

| Konsumsi Air | 2–4 m³/jam |

| Panjang Garis | 20m–70m (berdasarkan kapasitas & tata letak) |

Semua bagian yang bersentuhan dengan makanan bertemu FDA, Ce, Dan Iso 22000 standar.

10. Tata Letak dan Perencanaan Ruang

Perencanaan tata letak pabrik yang tepat membantu memastikan efisiensi alur kerja, keamanan pangan, dan kemudahan pembersihan. Garis mie instan skala menengah (MISALNYA., 150,000 bungkus/hari) biasanya membutuhkan:

- Kawasan Pabrik: 800–1.500 m²

- Zona:

- Penerimaan bahan baku & penyimpanan

- Area pengolahan adonan dan pengukusan

- Bagian mengeringkan atau menggoreng

- Pendinginan & zona pengemasan

- Pengepakan terakhir & menugaskan

- Pertimbangan:

- Aliran linier dari mentah hingga produk jadi

- Pisahkan pintu masuk/keluar untuk bahan baku dan staf

- Sistem drainase untuk CIP mudah (Bersih di tempat)

- Kelembaban terkontrol di area pengeringan

11. Persyaratan Energi dan Utilitas

Estimasi energi dan utilitas yang tepat sangat penting untuk penganggaran dan rekayasa pabrik.

| Sumber | Perkiraan Konsumsi (Per 1000 kg) |

|---|---|

| Listrik | 150–250 kWh |

| Uap | 300–500kg |

| Air | 2–4 m³ |

| Udara Terkompresi | 5–10 m³/jam |

| Minyak Goreng (jika digunakan) | 0.8–1,2 kg per kg blok mie |

Anda dapat mengoptimalkan konsumsi menggunakan:

- Sistem pemulihan panas

- Pembakar efisiensi tinggi

- Motor yang dikendalikan VFD

- Pemanas awal tenaga surya

12. Sistem Otomasi dan Kontrol

Jalur mi instan modern sangat otomatis, mengintegrasikan sistem kontrol PLC dan HMI untuk memastikan konsistensi dan pemantauan:

Fitur Utama:

- Panel kontrol layar sentuh (HMI)

- Integrasi SCADA untuk analisis waktu nyata

- Sistem manajemen resep

- Diagnostik jarak jauh IoT

- Sensor untuk tekanan, suhu, kecepatan

- Alarm otomatis dan deteksi kesalahan

Operator dapat beralih antar produk, menyesuaikan parameter, atau pantau peringatan pemeliharaan langsung dari layar.

13. Kapasitas dan Skalabilitas Lini Produksi

Lini produksi tersedia dalam berbagai konfigurasi untuk disesuaikan dengan setiap ukuran bisnis:

| Skala produksi | Kapasitas output (Paket/Hari) | Ideal untuk |

|---|---|---|

| Skala kecil | 20,000–50.000 | Toko mie lokal, UKM |

| Skala menengah | 80,000–150.000 | Produsen makanan daerah |

| Skala besar | 200,000–300.000+ | Eksportir, merek global |

Garis dapat ditingkatkan dengan:

- Menambahkan lebih banyak terowongan pengeringan/penggorengan

- Meningkatkan ke unit pengemasan multi-kepala

- Memasang lengan pick-and-place robot

14. Prosedur Perawatan dan Pembersihan

Perawatan yang tepat menjamin umur panjang, kebersihan, dan kinerja.

Tugas Harian:

- Bersihkan cetakan ekstruder dan ruang pengukus

- Tiriskan dan saring minyak goreng (jika berlaku)

- Sanitasi pisau pemotong dan ban berjalan

Tugas Mingguan:

- Cip: perpipaan bersih di tempatnya, jalur uap

- Ganti oli di gearbox, pelumasan motor

- Pembersihan filter udara dan filter air

Tugas Bulanan:

- Kalibrasi sensor dan sistem PLC

- Ganti sabuk atau lembaran Teflon yang sudah usang

Menggunakan deterjen yang aman untuk makanan Dan pelapis anti-mikroba untuk mencegah kontaminasi.

15. Sertifikasi Keamanan dan Kepatuhan Pangan

Lini produksi mie instan Anda harus mematuhi standar berikut:

| Sertifikasi | Keterangan |

|---|---|

| Ce | Kepatuhan keselamatan dan permesinan Eropa |

| Iso 22000 / Haccp | sistem manajemen keamanan pangan |

| FDA / LFGB | Keamanan material untuk permukaan yang bersentuhan dengan makanan |

| GMP | Praktik Manufaktur yang Baik |

| Laporan SGS/BV | Verifikasi independen atas peralatan dan kebersihan |

Produsen harus menyediakan dokumentasi lengkap termasuk:

- Skema kelistrikan

- Panduan pengguna dan pembersihan

- Jadwal pemeliharaan

- Daftar suku cadang

16. Produsen Utama dan Pemasok Global

Saat memilih pemasok, mempertimbangkan:

- Pengalaman dan reputasi

- Ketersediaan suku cadang

- Pelatihan dan dukungan

- Kemampuan penyesuaian

Pemasok Global Teratas:

- Teknik Nissin (Jepang)

- Grup Buhler (Swiss)

- Grup Pavan / Gea (Italia)

- DT Food Machine Co., Ltd. (Cina)

- Mesin Makanan Anko (Taiwan)

- Sistem Pangan Unitherm (Amerika Serikat)

17. Analisis Biaya Investasi dan ROI

Investasi tergantung pada skala output, tingkat otomatisasi, dan konfigurasi.

| Tipe Garis | Perkiraan biaya (USD) |

|---|---|

| Skala kecil | $50,000–$100.000 |

| Skala menengah | $150,000–$300.000 |

| Skala besar | $400,000–$800.000+ |

Faktor ROI:

- Permintaan pasar lokal

- Margin keuntungan per bungkus

- Penghematan biaya tenaga kerja

- Biaya pengemasan per unit

Kebanyakan pabrik mengembalikan investasi dalam waktu 12–24 bulan.

18. Studi Kasus dan Aplikasi Industri

Studi kasus 1: Vietnam – Jalur Skala Menengah

- Keluaran: 120,000 bungkus/hari

- Kemasan: paket bantal dengan tiga sachet

- ROI: 16 bulan

Studi kasus 2: Kenya – Jalur Non-Goreng

- Keluaran: 30,000 mie gelas/hari

- Didukung oleh sistem pemanasan awal tenaga surya

- ROI: 22 bulan

Studi kasus 3: Meksiko – Jalur Ekspor Skala Besar

- Keluaran: 300,000 bungkus/hari

- Integrasi SCADA yang sepenuhnya otomatis

- Ekspor ke Amerika dan Kanada

19. Masalah Umum dan Pemecahan Masalah

| Masalah | Menyebabkan | Larutan |

|---|---|---|

| Untaian mie patah | Pemotong terlalu tercampur atau tumpul | Sesuaikan ketegangan terpal, ganti bilah |

| Degradasi minyak | Menggunakan kembali terlalu banyak siklus | Gunakan filtrasi otomatis atau sensor oli |

| Ketidakselarasan kemasan | Waktu mati atau kegagalan sensor | Kalibrasi ulang sensor dan sinkronisasi konveyor |

| Mie menempel di penggorengan | Gelatinisasi pati yang salah | Periksa kembali suhu pengukusan |

20. RFQ – Pertanyaan yang Sering Diajukan

Q1: Bisakah saya menyesuaikan bentuk dan ukuran kue mie?

Ya. Anda dapat menyesuaikan cetakan, piring mati, dan ukuran pemotong.

Q2: Apa perbedaan mie goreng dan non goreng secara mesin?

Mie goreng membutuhkan penggorengan, filter oli, dan kap knalpot; mie yang tidak digoreng gunakan terowongan kering udara yang lebih panjang dan optimalisasi uap.

Q3: Berapa lama waktu pemasangannya?

Khas 30–60 hari, termasuk pelatihan.

Q4: Bisakah satu lini memproduksi paket cangkir dan bantal?

Ya, dengan modul pengemasan yang dapat dipertukarkan.

Q5: Apakah bahasa lokal didukung dalam sistem kontrol?

Ya, Panel HMI dapat diprogram beberapa bahasa.

Q6: Bisakah bumbu dimasukkan secara otomatis?

Ya. Dispenser sachet menangani beberapa paket per paket.

Q7: Berapa tingkat konsumsi minyak?

Dengan kasar 0.8–1,2 kg minyak per kg mie untuk jenis goreng.

Q8: Apakah mudah untuk mengganti produk atau ukuran?

Ya. Kebanyakan jalur mengizinkan pergantian tanpa alat dalam 30–60 menit.

Q9: Jenis tenaga kerja apa yang dibutuhkan?

Sederet 150,000 paket/hari mungkin perlu 6–10 operator per shift.

Q10: Dukungan pemeliharaan apa yang tersedia?

Penawaran pabrikan diagnostik jarak jauh, suku cadang, Dan kunjungan di lokasi.

21. Inovasi Masa Depan dalam Pengolahan Mie Instan

- Kamera Inspeksi Bertenaga AI untuk mendeteksi cacat secara real-time

- Penggorengan Cerdas dengan manajemen oli adaptif

- Bahan kemasan ramah lingkungan seperti film biodegradable

- Sistem plug-and-play modular untuk ekspansi cepat

- Lengan robot untuk karton dan pembuatan palet

- Konektivitas IoT untuk pemeliharaan prediktif

22. Kesimpulan: Mengapa Berinvestasi pada Produk dengan Kemasan Terintegrasi?

Terintegrasi penuh lini produksi mie instan dengan mesin pengemas penawaran:

- Produktivitas dan margin keuntungan lebih tinggi

- Mengurangi tenaga kerja manual dan kesalahan manusia

- Peningkatan keamanan dan ketertelusuran pangan

- ROI lebih cepat dengan operasi yang terukur

- Keunggulan kompetitif di pasar domestik dan ekspor

Baik Anda seorang startup atau merek makanan global, Investasi inilah yang menjadi tulang punggung kesuksesan industri mie instan saat ini.