Pengantar Lini Produksi Kentang Goreng

Itu Jalur produksi kentang goreng merupakan peralatan penting dalam industri pengolahan makanan, dirancang untuk mengotomatiskan produksi massal kentang goreng yang renyah dan lezat dari kentang segar. Baik di rantai makanan cepat saji, Pabrik Makanan Beku, atau pemasok katering, tuntutan efisiensi tinggi, kontinu, dan jalur produksi yang higienis telah meroket. Artikel ini akan memandu Anda melalui setiap aspek lini produksi kentang goreng, mulai dari persiapan bahan baku hingga pengemasan akhir, berfokus pada fungsinya, komponen, manfaat, dan aplikasi.

Apa Itu Lini Produksi Kentang Goreng?

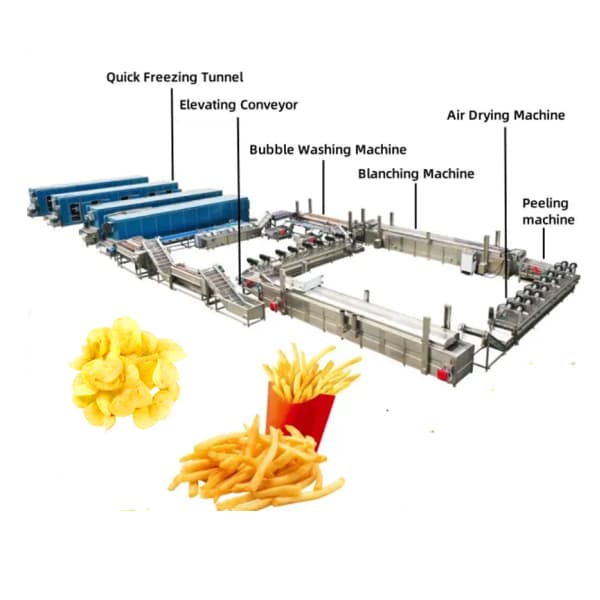

Kentang sepenuhnya otomatis Jalur produksi kentang goreng adalah serangkaian mesin yang saling berhubungan yang melaksanakan tugas tertentu seperti mencuci, mengelupas, pemotongan, pucat, pengeringan, penggorengan, menghilangkan minyak, pembekuan, dan pengemasan. Sistem ini menjamin keseragaman, mencicipi, dan keamanan kentang goreng pada skala industri.

Salurannya bisa semi-otomatis atau otomatis penuh, dan biasanya dirancang untuk menangani berbagai kapasitas, dari operasi skala kecil hingga produksi komersial skala besar yang melebihi beberapa ton per jam.

Komponen Utama Lini Produksi Kentang Goreng

1. Mesin cuci dan pengupas kentang

Ini adalah langkah pertama dalam jalur produksi. Mesin cuci menghilangkan kotoran, Batu, dan benda asing lainnya, sedangkan mesin pengupasnya menggunakan rol atau sikat ampelas untuk menghilangkan kulitnya tanpa merusak daging kentang.

Fitur Utama:

- Efisiensi tinggi

- Konsumsi air rendah

- Kerusakan minimal pada kentang

2. Mesin Pemotong Kentang

Setelah dibersihkan dan dikupas, kentang dimasukkan ke dalam mesin pemotong yang mengirisnya menjadi potongan-potongan yang seragam. Ukurannya dapat disesuaikan berdasarkan kebutuhan produk tertentu.

Ukuran Potongan Populer:

- 7×7 mm

- 10×10mm

- 12×12mm (untuk kentang goreng kental)

3. Mesin Pembilasan dan Blanching

Blanching sangat penting untuk:

- Menghilangkan kelebihan pati

- Mempertahankan warna alami

- Menyiapkan kentang goreng untuk digoreng atau dibekukan

Mesin ini menggunakan air panas atau uap pada suhu terkontrol untuk merebus strip.

4. Dehidrator (Pengering Udara atau Mesin Dewatering)

Setelah blansing, kentang goreng perlu dikeringkan untuk mengurangi kadar airnya. Hal ini meningkatkan kualitas produk akhir dan mengurangi penyerapan minyak selama menggoreng.

5. Mesin penggorengan kontinu

Penggorengan terus menerus memastikan penggorengan kentang goreng merata pada suhu yang konsisten. Suhu minyak dan waktu penggorengan dikontrol secara otomatis untuk memastikan lapisan luar yang renyah dan tekstur bagian dalam yang lembut.

Minyak Goreng Yang Digunakan:

- Minyak kelapa sawit

- Minyak bunga matahari

- minyak kedelai

6. Mesin de-oiling

Pasca penggorengan, de-oiler sentrifugal menghilangkan kelebihan minyak, membuat kentang goreng tidak terlalu berminyak dan lebih sehat. Langkah ini juga meningkatkan umur simpan dan rasa.

7. Mesin beku (Untuk Kentang Goreng Beku)

Untuk produk beku, kentang goreng dikirim ke IQF (Pembekuan Cepat Individu) terowongan untuk menjaga kesegaran dan tekstur. Mesin ini membekukan kentang goreng dalam hitungan menit pada suhu -18°C atau lebih rendah.

8. Mesin pengemasan

Langkah terakhir adalah mengemas kentang goreng yang sudah jadi. Mesin pengemas vakum atau berisi nitrogen sering digunakan untuk memperpanjang umur simpan.

Format Kemasan:

- Kantong plastik

- Kotak karton

- Kantong tertutup

Tabel Spesifikasi Teknis

| Nama mesin | Model | Kapasitas (kg/jam) | Kekuatan (kW) | Bahan |

|---|---|---|---|---|

| Pencucian & Mesin pengupas | WP-1000 | 1000 | 3.0 | Baja tahan karat |

| Mesin Pemotong Kentang | PC-600 | 600 | 1.5 | Baja tahan karat |

| Mesin pucat | BM-1000 | 1000 | 15 | MILIK MEREKA 304 |

| Dehidrator | DH-800 | 800 | 2.2 | MILIK MEREKA 304 |

| Mesin penggorengan | goreng-1000 | 1000 | 36 | MILIK MEREKA 304 |

| Mesin de-oiling | LAKUKAN-800 | 800 | 1.5 | MILIK MEREKA 304 |

| Terowongan Pembekuan | IQF-1000 | 1000 | 40 | Baja tahan karat |

| Mesin Pengepakan | PM-300 | 300 tas/jam | 2.5 | MILIK MEREKA 304 |

Alur Kerja Lini Produksi Kentang Goreng

- Memberi Makan Kentang Mentah

- Mencuci dan mengelupas

- Memotong menjadi Strip

- Membilas dan Memucat

- Dehidrasi

- Penggorengan

- De-oiling

- Pendinginan atau Pembekuan

- Pengemasan dan Penyegelan

Proses sistematis ini menjamin kebersihan, konsistensi, dan produktivitas di seluruh lini.

Keuntungan Menggunakan Lini Produksi Kentang Goreng Otomatis

✅ Efisiensi tinggi

Sistem otomatis mengurangi ketergantungan tenaga kerja dan meningkatkan output harian secara signifikan.

✅ Kualitas yang konsisten

Otomatisasi memastikan setiap benih memiliki ukuran yang konsisten, warna, dan rasanya.

✅ Produksi Higienis

Mesin dibuat dari baja tahan karat dan mematuhi standar keamanan pangan (Haccp, Iso, Ce).

✅ Penghematan Energi dan Minyak

Sistem modern mendaur ulang minyak goreng dan menggunakan sistem pemanas hemat energi.

✅ Dapat disesuaikan

Lini produksi dapat disesuaikan dengan kebutuhan klien: kentang goreng beku, kentang goreng segar, kentang goreng keriting, atau kentang goreng.

Penerapan Lini Produksi Kentang Goreng

Lini produksi kentang goreng digunakan dalam berbagai situasi:

- Pabrik Pengolahan Makanan Beku

- Rantai Makanan Cepat Saji

- Layanan Katering

- Kantin Sekolah dan Rumah Sakit

- Produsen Makanan Ringan

- Startup dan Pabrik Makanan UKM

Mereka ideal untuk keduanya kentang goreng beku Dan kentang goreng panas siap disantap.

Tip Perawatan dan Pembersihan

- Pembersihan harian: Pastikan setiap mesin dibersihkan dengan disinfektan food grade.

- Ganti Oli Secara Reguler: Ganti minyak penggorengan pada interval yang disarankan.

- Pelumasan: Bagian mekanis harus dilumasi sesuai panduan perawatan.

- Inspeksi: Inspeksi mingguan membantu mengidentifikasi potensi kerusakan sejak dini.

Cara Memilih Lini Produksi Kentang Goreng yang Tepat

Saat memilih garis, Pertimbangkan yang berikut:

- Kapasitas produksi (kg/jam atau ton/hari)

- Jenis Produk Akhir (beku, segar, kentang goreng berlapis)

- Kendala anggaran

- Ketersediaan Ruang

- Level Otomasi (semi atau sepenuhnya otomatis)

- Layanan purna jual & Jaminan

Bekerja sama dengan produsen tepercaya yang dapat menyediakan pemasangan, pelatihan, dan kustomisasi.

Perkiraan Biaya Lini Produksi Kentang Goreng

Harganya bervariasi berdasarkan kapasitas, tingkat otomatisasi, dan konfigurasi.

| Kapasitas Jalur | Otomatisasi | Kisaran harga (USD) |

|---|---|---|

| 200–300kg/jam | Semi | $20,000–$40.000 |

| 500–800kg/jam | Penuh | $60,000–$90.000 |

| 1–2 ton/jam | Penuh | $120,000–$200.000 |

| >5 ton/jam | Industri | $300,000+ |

🧪 Analisis Mendalam Setiap Langkah Pemrosesan

🥔 1. Seleksi Kentang dan Pengendalian Mutu

Tidak semua kentang cocok untuk kentang goreng. Varietas bertepung tinggi seperti Russet Burbank atau Innovator lebih disukai karena tekstur dan perilaku penggorengannya.

Parameter pra-penyortiran meliputi:

- Ukuran: Seragam ukuran sedang hingga besar

- Kulit: Minimal memar dan bertunas

- Kandungan bahan kering: Ideal >20%

Dengan mengotomatiskan sistem penyortiran visual atau laser, produsen mengurangi cacat pada tahap awal, menghemat biaya hilir.

🧼 2. Teknik Mencuci Tingkat Lanjut

Sistem pencucian modern menggunakan nozel semprot bertekanan tinggi, sikat putar, dan sirkulasi gelembung untuk menghilangkan tidak hanya tanah tetapi juga residu pestisida.

Beberapa sistem terintegrasi:

- Tangki daur ulang air

- Filter sedimen

- alat sterilisasi UV

Hal ini mengurangi konsumsi air dan memenuhi standar pengolahan ramah lingkungan.

🧊 3. Optimasi Suhu Blanching

Blanching yang tepat biasanya dilakukan pada 75–85°C selama 3–5 menit tergantung pada ukuran strip.

Manfaat blansing:

- Menonaktifkan enzim

- Meningkatkan warna goreng

- Mencegah pembentukan akrilamida

- Menstabilkan tekstur

Beberapa baris digunakan blancher udara panas untuk kinerja hemat energi.

🔥 4. Penggorengan: Rasa & Ilmu Tekstur

Faktor kunci:

- Suhu minyak: 160°C–180 °C

- Waktu: 30–60 detik untuk menggoreng terlebih dahulu (dalam kentang goreng beku), lebih lama untuk segar

Termasuk penggorengan efisiensi tinggi:

- Penukar panas

- Filtrasi otomatis

- Sistem penyeimbang level minyak

Penggunaan penggorengan multi-zona memungkinkan penyesuaian untuk berbagai produk akhir (MISALNYA., kentang goreng berkerut vs kentang goreng yang sedikit).

🥶 Jenis Kentang Goreng dan Penyesuaian Lini Produksi

| Jenis Kentang Goreng | Perbedaan Garis | Bentuk Akhir |

|---|---|---|

| Kentang Goreng Beku | Termasuk pembekuan KKNI, kemasan nitrogen | Produk beku |

| Kentang Goreng Segar | Membutuhkan konveyor pendingin, pengiriman cepat | Kantong siap digoreng |

| Kentang Goreng yang Dilapisi | Aplikator pelapis + pengering ekstra setelah blansing | Crispy, dilapisi adonan |

| Kentang Goreng Keriting/Wafel | Pemotong khusus + unit penggorengan presisi lebih tinggi | Tekstur khusus |

| Kentang Goreng Rasa Pedas | Gelas bumbu + penyemprot minyak + dosis rasa | Camilan yang sudah dibumbui |

Setiap jenis memerlukan konfigurasi tertentu, dari kecepatan menggoreng hingga pengaduk bumbu.

❓ RFQ umum (Pertanyaan yang sering diajukan)

Q1: Berapa banyak pekerja yang dibutuhkan untuk jalur 500kg/jam?

A: Untuk saluran yang sepenuhnya otomatis: 3–5 operator (makanan, pemantauan, kemasan). Semi-otomatis mungkin memerlukan hingga 8–10.

Q2: Bisakah lini mengolah sayuran umbi-umbian lainnya seperti ubi atau talas?

A: Ya. Dengan sedikit penyesuaian bilah dan perubahan waktu blansing, bisa mengolah ubi jalar, wortel, atau potongan singkong.

Q3: Sertifikasi apa yang diperlukan untuk ekspor ke UE/AS?

A:

- Ce (Kepatuhan UE)

- Bahan yang sesuai dengan FDA (untuk Amerika Serikat)

- Iso 9001 / Haccp

Q4: Berapa waktu tunggu setelah pemesanan?

A: Biasanya 25–45 hari kerja tergantung pada penyesuaian dan kapasitas mesin.

Q5: Bisakah minyak digunakan kembali di penggorengan?

A: Ya. Sistem ini mencakup filter oli otomatis dan sistem sirkulasi untuk menggunakan kembali oli bersih dengan aman.

🏭 Pemasok yang Direkomendasikan: DT Food Machine Co., Ltd.

Jika Anda mencari produsen tepercaya dengan pengalaman global, DT Food Machine Co., Ltd. menonjol sebagai ahli terkemuka di lini produksi kentang goreng.

Mengapa DT Food Machine Co., Ltd.?

- 🛠 20+ pengalaman manufaktur selama bertahun-tahun

- 📦 Solusi siap pakai mulai dari pemuat kentang hingga pengemasan

- 🌍 Diekspor ke 60+ negara-negara termasuk Amerika Serikat, Meksiko, Arab Saudi, Nigeria

- 🧰 Menyediakan instalasi di tempat dan dukungan video jarak jauh

- 🧪 Menawarkan R&Layanan D untuk penyesuaian rasa dan aplikasi pelapisan

Model populer:

- DT-goreng1000 - - 1000 saluran otomatis kg/jam

- DT-MINI500 – Kompak 500 garis kg/jam untuk startup

- DT-IQF2000 – Kentang goreng beku dilapisi dengan freezer spiral

📞 Hubungi DT Food Machine Co., Ltd. melalui email atau WhatsApp untuk kutipan atau gambar teknik.

📈 Tren Industri Produksi Kentang Goreng

1. Otomatisasi Cerdas & Integrasi IoT

Garis lanjutan menampilkan PLC dengan antarmuka layar sentuh, pelacakan data waktu nyata, peringatan pemeliharaan prediktif, dan integrasi awan.

2. Penggorengan Ramah Lingkungan

Sistem baru menggunakan pembakar hemat energi, pengeringan dengan bantuan sinar matahari, dan penyaringan minyak untuk mengurangi jejak karbon.

3. Boom Kustomisasi Rasa

Lini permintaan merek makanan ringan global yang mampu mengaplikasikan berbagai lapisan rasa (MISALNYA., cabai-jeruk nipis, truffle, keju), didorong oleh variasi permintaan konsumen.

4. Desain modular kompak

Sistem modular kecil memungkinkan peningkatan dan pemeliharaan yang mudah, sangat bermanfaat untuk fasilitas skala kecil hingga menengah.

📌 Kesimpulan: Buktikan Masa Depan Bisnis Kentang Goreng Anda

Dirancang dengan baik Jalur produksi kentang goreng adalah tulang punggung keberhasilan pembuatan makanan ringan kentang. Dengan konfigurasi yang tepat, Anda bisa menghasilkan apa saja mulai dari kentang goreng beku klasik hingga pedas, potongan gourmet yang dibumbui.

Memilih jalur yang tepat artinya:

- ROI yang lebih baik

- Lebih sedikit biaya tenaga kerja

- Konsistensi produk lebih tinggi

- Kepatuhan terhadap peraturan ekspor

Baik Anda seorang startup atau perusahaan makanan multinasional, berinvestasi dalam kualitas tinggi, lini produksi kentang goreng otomatis adalah kunci penskalaan dengan keunggulan dan keberlanjutan.