Perkenalan: Merevolusi Pembuatan Biskuit

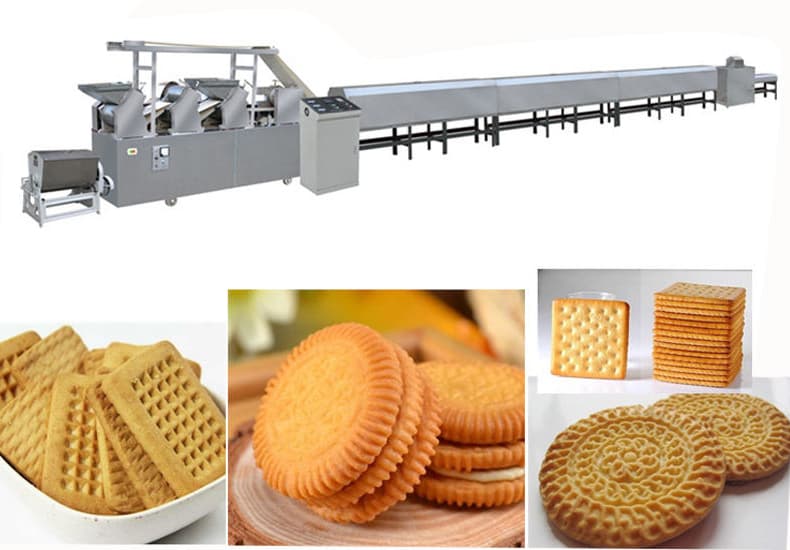

Permintaan global akan biskuit berkualitas tinggi terus meningkat, didorong oleh preferensi konsumen terhadap kenyamanan, lezat, dan makanan ringan yang terjangkau. Untuk memenuhi permintaan yang terus meningkat ini sambil memastikan konsistensi, kebersihan, dan efisiensi, A lini produksi biskuit sepenuhnya otomatis telah menjadi standar emas dalam industri manufaktur makanan.

Artikel ini menyajikan gambaran komprehensif tentang modern lini produksi biskuit, merinci mesin yang terlibat, aliran produksi, spesifikasi teknis, fitur otomatisasi, dan keuntungan bisnis bagi pabrik biskuit di seluruh dunia.

1. Apa Itu Lini Produksi Biskuit Sepenuhnya Otomatis?

A lini produksi biskuit sepenuhnya otomatis adalah sistem permesinan terintegrasi yang dirancang untuk mengolah bahan mentah menjadi bahan jadi, biskuit kemasan melalui operasi otomatis. Ini menghilangkan kebutuhan akan tenaga kerja manual di berbagai tahapan seperti pencampuran, pembentukan, pembakaran, pendinginan, dan pengemasan.

Dari kue mentega klasik hingga biskuit sandwich berisi krim, lini produksi ini mengakomodasi berbagai jenis produk dengan presisi tinggi dan limbah minimal.

2. Komponen Utama Lini Produksi Biskuit

Seorang profesional lini produksi biskuit terdiri dari peralatan utama berikut:

2.1 Pengaduk Adonan

- Mencampur tepung, gemuk, air, gula, dan bahan tambahan menjadi adonan seragam.

- Pilihan: Pencampur horisontal, pengaduk spiral vertikal.

2.2 Konveyor Pengumpan Adonan

- Pindahkan adonan ke mesin pembentuk.

- Pengontrol kecepatan dengan konstruksi baja tahan karat.

2.3 Mesin Pembentuk Biskuit

- Jenis: Mesin cetak putar, pemotong putar, potong kawat, atau ekstruder.

- Cetakan khusus untuk berbagai bentuk dan pola biskuit.

2.4 Oven Pemanggang Terowongan

- Sumber panas: Listrik, gas, Diesel, atau inframerah.

- Pemanggangan seragam dengan zona suhu untuk kontrol yang presisi.

2.5 Penyemprot Minyak (Opsional)

- Oleskan minyak atau glasir untuk meningkatkan kilau dan rasa.

2.6 Konveyor Pendingin Biskuit

- Mengurangi suhu biskuit yang dipanggang sebelum dikemas.

- Memastikan kekencangan produk dan mencegah kondensasi.

2.7 Jalur Pengemasan

- Jenis: Pembungkus aliran horizontal, segel pengisian formulir vertikal (Vffs).

- Fitur: Pengkodean tanggal, pembilasan nitrogen, aplikasi label.

3. Spesifikasi Teknis

| Parameter | Spesifikasi |

|---|---|

| Kapasitas produksi | 100 kg/h to 2000 kg/jam |

| Jenis Biskuit Didukung | Biskuit keras, biskuit lembut, sandwich, cookie |

| Panjang Oven | 20m–60m (dapat disesuaikan) |

| Sumber Panas | Listrik / Gas / solar / LPG |

| Kebutuhan Daya | 50 kW – 200 kW (bervariasi berdasarkan konfigurasi) |

| Tegangan Operasi | 380V/50Hz 3 Fase (dapat disesuaikan) |

| Sistem Kontrol | Plc + HMI (panel layar sentuh) |

| Bahan | Stainless steel grade makanan Sus304 |

| Kecepatan Cetakan | Hingga 25–40 cetakan/menit (tergantung pada jenisnya) |

| Kecepatan pengemasan | 20–120 bungkus/menit |

4. Alur Proses Produksi

Melangkah 1: Persiapan Adonan

Bahan-bahan ditimbang dan dicampur dalam mixer otomatis.

Melangkah 2: Penyampaian Adonan

Adonan yang tercampur dipindahkan ke sistem pembentuk tanpa kontak manusia.

Melangkah 3: Pembentukan Biskuit

Biskuit dibentuk menggunakan pemotong putar atau ekstruder, membentuk lembaran adonan atau kue individu.

Melangkah 4: Pembakaran

Biskuit yang dibentuk melewati oven terowongan dengan beberapa zona suhu.

Melangkah 5: Pendinginan

Biskuit yang dipanggang didinginkan secara merata melalui kipas konveyor untuk mempertahankan bentuk dan teksturnya.

Melangkah 6: Kemasan

Biskuitnya sejajar, terhitung, dan dikemas ke dalam tas, nampan, atau karton secara otomatis.

5. Jenis Biskuit yang Diproduksi

A lini produksi biskuit dapat memproduksi berbagai gaya biskuit termasuk:

| Jenis Biskuit | Keterangan |

|---|---|

| Biskuit Keras | Rendah gula/lemak, tekstur renyah (MISALNYA., Marie, Soda) |

| Biskuit Lembut | Tinggi gula/lemak, tekstur lembut (MISALNYA., roti pendek) |

| Biskuit Sandwich Krim | Dua biskuit dengan isian krim |

| kue | Tebal, tekstur kenyal (sering kali terbentuk potongan kawat) |

| Biskuit Wafer | Lapisan tipis dengan isian krim |

6. Otomatisasi & Fitur Cerdas

- Panel Kontrol PLC – Pemantauan dan penyesuaian parameter secara real-time.

- Layar Sentuh HMI – Antarmuka yang ramah pengguna untuk pengaturan resep.

- Sensor Suhu – Pengaturan suhu oven multi-zona.

- Penggerak Motor Servo – Untuk pembentukan dan penyelarasan biskuit yang presisi.

- Pemeliharaan Jarak Jauh (Opsional) – Dukungan melalui koneksi cloud IoT.

7. Keuntungan Lini Produksi Biskuit Sepenuhnya Otomatis

✅ 1. Peningkatan efisiensi

Kontinu, produksi berkecepatan tinggi dengan waktu henti minimal.

✅ 2. Kualitas produk yang konsisten

Dosis bahan yang akurat, pembentukan, dan memanggang memastikan setiap biskuit seragam.

✅ 3. Pengurangan Biaya Tenaga Kerja

Pengoperasian yang sepenuhnya otomatis secara drastis mengurangi kebutuhan tenaga kerja manual.

✅ 4. Kebersihan dan Keamanan

Pemrosesan tertutup dengan peralatan baja tahan karat food grade memenuhi standar HACCP dan GMP.

✅ 5. Optimasi Energi

Oven dan konveyor modern dirancang untuk efisiensi energi.

8. Pertimbangan Tata Letak Pabrik

Pabrik biskuit harus dirancang berdasarkan:

- Kapasitas produksi

- Ruang untuk penyimpanan bahan mentah dan barang jadi

- Zona ventilasi dan insulasi panas

- Pisahkan zona untuk adonan, pembakaran, pendinginan, dan pengemasan

- Ketersediaan pasokan listrik dan air

Tata letak tipikal dapat berkisar dari 25 meter ke atas 100 panjangnya meter tergantung keluaran dan jenis biskuitnya.

9. Studi kasus: 1000 kg/jam Lini Produksi Biskuit

Klien: Produsen Makanan Ringan di Asia Tenggara

Sorotan Pengaturan:

- 60-oven gas meteran

- Pemotong putar ganda untuk variasi bentuk

- Mesin pengemas horizontal berisi nitrogen

- 24/7 operasi, tiga shift

Hasil:

- Produksi meningkat 4×

- Limbah dikurangi sebesar 35%

- ROI dicapai pada 14 bulan

10. Pertanyaan Umum Pembeli (Bagian RFQ)

Q1: Berapa kapasitas minimum yang tersedia?

A: Lini produksi biskuit terkecil kami dimulai pada 100 kg/jam, ideal untuk pabrik kecil dan menengah.

Q2: Dapatkah lini produksi menangani berbagai bentuk biskuit??

A: Ya, cetakan dapat dengan cepat diganti untuk mendukung berbagai bentuk dan pola.

Q3: Apakah pelatihan operator disediakan?

A: Ya, kami menyediakan pelatihan di tempat atau jarak jauh untuk staf Anda.

Q4: Bisakah jalur tersebut berintegrasi dengan pabrik yang sudah ada?

A: Sangat. Kami menyesuaikan tata letak agar sesuai dengan infrastruktur yang ada.

Q5: Berapa lama waktu pengiriman?

A: Pengiriman standar adalah 35–60 hari tergantung penyesuaian.

11. Pemeliharaan dan Dukungan

- Jadwal Pemeliharaan Preventif

Pemeriksaan rutin pada bantalan, ikat pinggang, motor, dan sensor. - Ketersediaan Suku Cadang

Pengiriman global yang cepat untuk komponen penting. - Diagnostik jarak jauh

Diaktifkan melalui router industri dan diagnostik PLC.

12. Harga & Hasil Investasi

| Kapasitas | Perkiraan Harga (USD) |

|---|---|

| 100–200kg/jam | $35,000 - - $60,000 |

| 300–500 kg/jam | $70,000 - - $120,000 |

| 800–1000 kg/jam | $150,000 - - $220,000 |

| 1500 kg/jam+ | $250,000 dan di atasnya |

Periode ROI: Khas 12 ke 24 bulan tergantung pada skala dan kondisi pasar.

13. Tren Pasar & Pandangan Masa Depan

- Meningkatnya permintaan untuk biskuit yang lebih sehat (gula rendah, bebas gluten).

- Meningkatnya investasi di pabrik pintar Dan Industri 4.0.

- Peningkatan peluang ekspor di Afrika, Timur Tengah, dan Amerika Latin.

14. Kesimpulan: Bangun Pabrik Biskuit Anda dengan Percaya Diri

Sepenuhnya otomatis lini produksi biskuit memberdayakan produsen makanan untuk menghasilkan produk berkualitas tinggi dalam skala besar dan konsisten, kebersihan, dan fleksibilitas. Baik Anda memulai pabrik biskuit atau meningkatkan fasilitas Anda, berinvestasi dalam teknologi produksi biskuit modern adalah landasan profitabilitas jangka panjang.

Siap untuk mengambil langkah selanjutnya? Hubungi kami untuk proposal yang disesuaikan, desain tata letak, dan kutipan.