En la industria de postres actual, Los crujientes conos de barquillo se han convertido en el alma de todo helado.. Desde las fábricas de helados más grandes del mundo hasta las heladerías boutique, un equipo impulsa silenciosamente este éxito: el fabricante de conos de oblea. esta maquina, preciso pero creativo, permite a los productores transformar ingredientes simples: la harina, azúcar, y aceite, en conos perfectamente horneados que definen el primer bocado del cliente..

Mientras los clientes disfrutan del sabor., Los dueños de negocios entienden que la clave para un sabor y una calidad consistentes radica en la propia máquina.. Elegir el derecho máquina para hacer conos de oblea No es sólo una decisión técnica sino una inversión estratégica en eficiencia., calidad, y reputación de marca.

La tecnología detrás de una máquina para fabricar conos de oblea

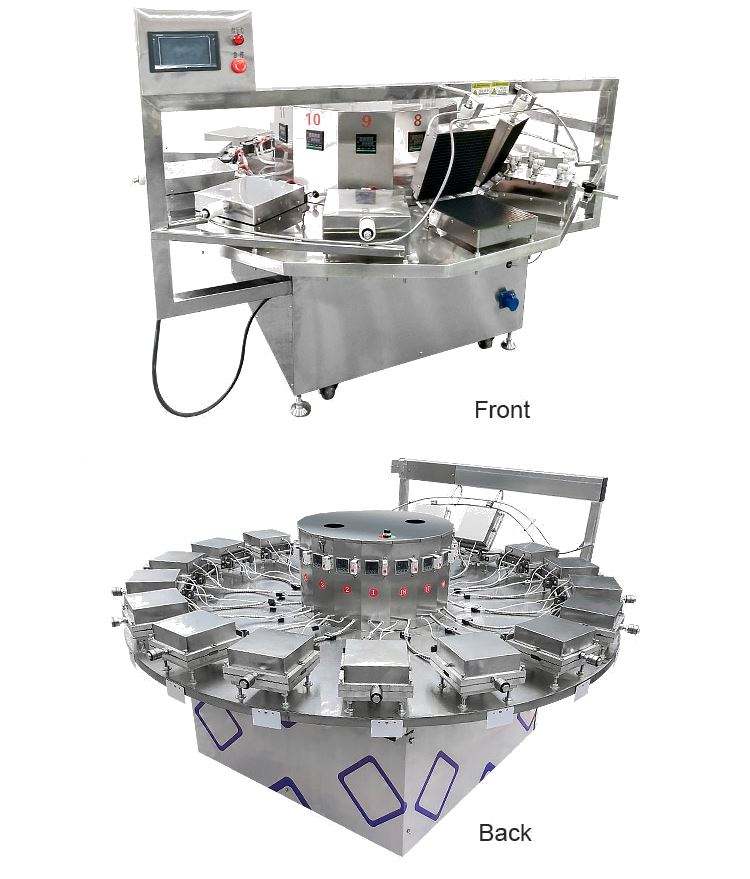

A diferencia de una plancha para gofres normal o una prensa de conos de uso doméstico, un profesional fabricante industrial de conos de oblea integra mecánica, térmico, y sistemas de control digital para manejar la producción a gran escala. Dentro de la maquina, El control preciso de la temperatura y el laminado automatizado garantizan que cada cono tenga el mismo color dorado., frescura, y textura.

El proceso de producción comienza con una masa especialmente formulada, mezclada en un tanque hasta que quede suave.. Luego, la masa se deposita uniformemente en placas para hornear calientes., formando láminas delgadas. En segundos, esas hojas son enrolladas en forma de cono por el unidad de laminación de cono, enfriado naturalmente en transportadores, y finalmente descargado para embalaje.

Todo el proceso es rápido., automático, y notablemente consistente. Para fabricantes que producen miles de conos al día, Esta automatización es crucial para satisfacer la demanda del mercado manteniendo una calidad uniforme..

Máquina automática de cono de oblea: Innovación para la eficiencia

El máquina automática de cono de oblea representa la evolución de la cocción tradicional en conos. Los modelos manuales más antiguos requerían que los trabajadores vertieran la masa y enrollaran cada cono individualmente, un proceso que requería mucha mano de obra.. Sistemas automáticos modernos., sin embargo, puede producir hasta 10,000 conos por hora con mínima supervisión.

Cada molde para hornear se abre y cierra rítmicamente., formando decenas de conos simultáneamente. El Panel de control con pantalla táctil PLC permite a los operadores establecer la temperatura de horneado, velocidad de rotación, y tamaño del cono con precisión. Los sistemas de calefacción a gas o eléctricos se pueden seleccionar según las necesidades de producción..

Esta innovación no solo aumenta la velocidad sino que también garantiza una mejor consistencia., Lo cual es vital para las marcas de helados que dependen de la uniformidad del producto..

Máquina para hacer conos de helado vs.. Máquina de cono de gofres

Muchos clientes se preguntan acerca de la diferencia entre un fabricante de conos de oblea y un fabricante de conos de gofre. Aunque ambos producen conos de helado., Sirven para diferentes propósitos y mercados..

A cono de oblea es delgado, crujiente, y luz. Se rompe con un crujido satisfactorio y es ideal para grandes, producción rentable. Es el cono que encontrarás en los supermercados., máquinas expendedoras, y marcas de helados de comida rápida.

A cono de gofre, en contraste, es mas grueso, más dulce, y a menudo elaborado fresco en las tiendas.. Su estampado y sabor caramelizado se adaptan a los postres premium.. Máquinas como la máquina para hornear conos de waffle o fabricante de conos de azúcar operar a temperaturas ligeramente más bajas y manejar masas más densas.

En otras palabras:

- Cono de oblea = producción industrial en masa, bajo costo por pieza.

- Cono de waffle = presentación artesanal, punto de precio más alto.

Comprender esta distinción ayuda a los inversores a elegir la maquinaria adecuada para su mercado objetivo..

El papel de la línea de producción de conos de oblea

Para fábricas a gran escala, una sola máquina a menudo no es suficiente. Ahí es donde un línea de producción de conos de oblea llegar.

Este sistema totalmente automatizado combina varias máquinas interconectadas:

- Mezclador de masa y tanque de almacenamiento – Prepara y alimenta la masa automáticamente.

- Horno para hornear galletas – Contiene decenas de moldes para horneado continuo..

- Máquina laminadora de conos – Enrolla cada hoja horneada en conos..

- Transportador de enfriamiento – Estabiliza la textura antes del envasado..

- Apilador y mostrador – Organiza los conos en lotes para envolverlos.

El resultado es un proceso optimizado capaz de producir 24/7, entregando miles de conos perfectos por hora con una mínima intervención humana.

Fabricantes como Máquina de alimentos DT Diseñar líneas modulares., Permitir a los clientes comenzar poco a poco y ampliar la capacidad a medida que crece el negocio..

Características importantes de la máquina comercial de conos de oblea

Al comprar un fabricante comercial de conos de oblea, Varias especificaciones clave determinan el rendimiento y el retorno de la inversión..

1. Construcción y durabilidad

La estructura de acero inoxidable apto para uso alimentario garantiza higiene y resistencia a la corrosión.. Los moldes de hierro fundido o aleación de aluminio mantienen el calor de manera uniforme.

2. Opciones de fuentes de energía

Disponemos de calefacción eléctrica y de gas.. Los modelos a gas calientan más rápido y se adaptan a entornos de alto rendimiento, mientras que los sistemas eléctricos son más limpios y más fáciles de instalar en interiores.

3. Control de temperatura y tiempo

Los termostatos digitales y los sistemas PLC garantizan un horneado preciso, evitando que los conos se doren demasiado o poco cocidos..

4. Formas y tamaños de cono personalizables

De conos pequeños del tamaño de un bocado (50 milímetros) a conos gigantes estilo waffle (115 milímetros), Los moldes se pueden personalizar según la forma., diámetro, y patrón.

5. Sistemas de seguridad

Botones de parada de emergencia, protección contra sobrecarga, y los ventiladores de refrigeración automáticos hacen que el entorno de producción sea seguro para los operadores.

Descripción técnica de la máquina industrial de cono de oblea

Una típica industria máquina para hornear conos de oblea Incluye de 24 a 60 pares de moldes dispuestos en un horno giratorio.. Cada par funciona automáticamente.: se vierte la masa, horneado, y enrollado en un bucle continuo.

| Parámetro | Especificación |

|---|---|

| Modelo | DT-WF800 |

| Voltaje | 380V / 50Hz |

| Fuerza | 12 - 18 kilovatios |

| Capacidad de salida | 5,000–10.000 conos/hora |

| Fuente de calefacción | Gas o Electricidad |

| Tamaño del cono | 60–115 milímetros |

| Sistema de control | Pantalla táctil PLC |

| Peso | 1,500 - 2,000 kilos |

| Material | Acero inoxidable + Molde de hierro fundido |

| Garantía | 12 meses |

Esta configuración permite largas horas de producción., bajo mantenimiento, y calidad consistente, convirtiéndolo en la columna vertebral de muchas fábricas de helados en todo el mundo..

Consideraciones de costos y eficiencia energética

El coste de la energía juega un papel importante en la rentabilidad a largo plazo de la producción de conos.. Un moderno fabricante de conos de oblea Con recuperación de calor y aislamiento inteligentes se puede reducir el uso de energía hasta en 20%. Los modelos a gas suelen ofrecer costes operativos más bajos, especialmente en regiones con altos precios de la electricidad.

El precio de un profesional máquina de cono de oblea varía ampliamente:

- Modelos manuales básicos: alrededor de 500 a 1.000 dólares estadounidenses

- Unidades semiautomáticas: USD $3000–$5000

- Líneas de conos de oblea completamente automáticas: USD $10,000–$50,000+

Si bien la inversión inicial puede parecer alta, La reducción del costo laboral y el aumento de la producción a menudo permiten a las empresas recuperar su inversión dentro de una o dos temporadas de producción..

Consejos de mantenimiento para una máquina de conos de oblea de larga duración

Mantener su máquina limpia y en buen estado garantiza confiabilidad y seguridad. Después de cada corrida de producción, limpie los moldes para hornear con un paño no abrasivo y elimine los residuos de masa. Una vez a la semana, inspeccionar piezas mecánicas y aplicar lubricante de calidad alimentaria a los componentes móviles.

Evite el uso de herramientas afiladas que puedan rayar las placas.. La calibración debe verificarse mensualmente para garantizar un calentamiento uniforme.. Muchas máquinas modernas de Máquina de alimentos DT vienen con sistemas de autodiagnóstico que muestran alertas si la temperatura o la velocidad de rotación se desvían del rango preestablecido.

El mercado mundial de fabricantes de conos de oblea

A medida que aumenta el consumo mundial de helado, especialmente en Asia, el Medio Oriente, y América Latina, el mercado de máquinas automáticas de cono de oblea continúa expandiéndose. Los productores locales están invirtiendo en maquinaria para satisfacer la creciente demanda interna en lugar de importar conos del extranjero..

Mejoras tecnológicas, como Control de temperatura impulsado por IA y quemadores energéticamente eficientes, hacer la producción más sostenible. Mientras tanto, Las opciones de personalización, como marcas en conos o diferentes diseños de bordes, ayudan a los fabricantes a diferenciar sus productos..

¿Por qué elegir DT Food Machine para su equipo de conos de oblea?

Al seleccionar un socio para su línea de producción de conos, la experiencia y el soporte son importantes. Máquina de alimentos DT se destaca como uno de los fabricantes más confiables de fabricantes de conos de oblea y máquinas de cono de gofres en China, exportando a más de 60 países.

La empresa ofrece:

- Moldes de conos diseñados a medida para diferentes formas y capacidades..

- Líneas de producción de conos de oblea llave en mano.

- Máquinas certificadas CE e ISO con sistemas de ahorro de energía..

- Servicio postventa integral, incluyendo formación en instalación y suministro de repuestos..

La filosofía de DT Food Machine es simple: construir máquinas que produzcan calidad y consistencia en todo momento.

Tendencias futuras en la producción de conos de oblea

La automatización y la digitalización están definiendo la próxima era del procesamiento de alimentos. Futuro máquinas para hornear conos de oblea utilizará sensores inteligentes para controlar los niveles de humedad, ajustar la temperatura de horneado en tiempo real, e incluso predecir las necesidades de mantenimiento antes de que se produzcan averías.

La sostenibilidad es otro foco: quemadores de gas ecológicos, envases reciclables, y la reducción del consumo de energía se están convirtiendo en factores clave para los compradores internacionales.

A medida que las cadenas mundiales de postres se expanden, demanda de servicios confiables y eficientes máquinas para hacer conos de helado seguirá aumentando, hacer de la inversión temprana en equipos avanzados un movimiento estratégico.

Construya un negocio de helados rentable con la máquina adecuada

A fabricante de conos de oblea es más que un simple equipo: es la base de toda marca de helado exitosa. Desde el aroma de los cucuruchos recién horneados hasta el crujiente bocado que deleita a los clientes, Todo comienza con la precisión y el rendimiento de su máquina..

Eligiendo el modelo correcto, manteniéndolo adecuadamente, y trabajar con un proveedor de confianza como Máquina de alimentos DT, puedes lograr un alto rendimiento, calidad consistente, y fuerte rentabilidad en su negocio de producción de conos.