1. Introducción a la producción de mantequilla de maní

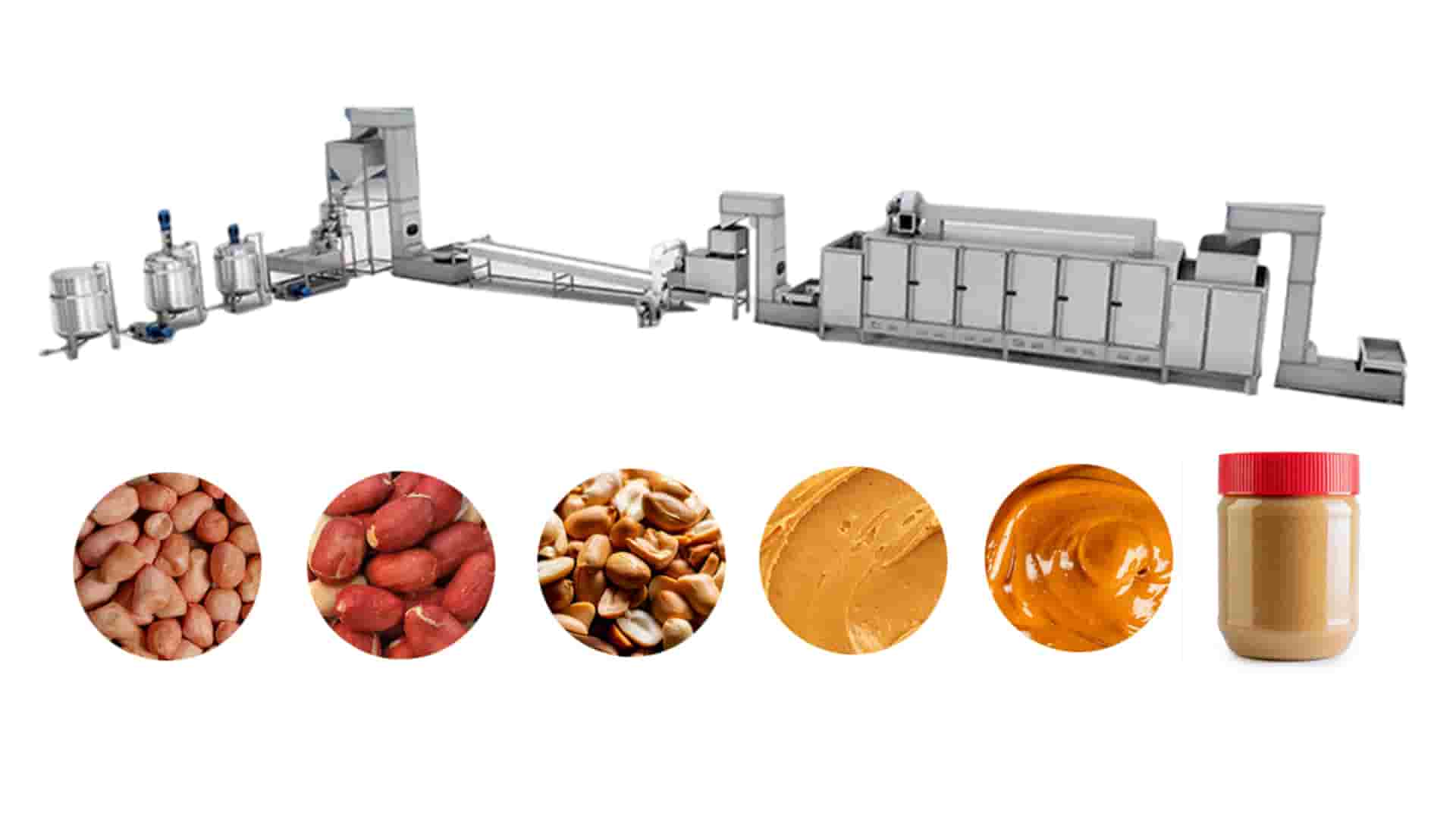

La mantequilla de maní es una crema para untar amada en todo el mundo, elaborado tostando y moliendo maní hasta obtener una pasta suave o crujiente. No es sólo un alimento básico en muchas dietas occidentales., pero también está ganando terreno en los mercados globales debido a su valor nutricional y versatilidad.. Un moderno línea de producción de mantequilla de maní ofrece eficiente, escalable, e higiénicas para el procesamiento comercial.

2. ¿Qué es una línea de producción de mantequilla de maní??

A línea de producción de mantequilla de maní es un sistema integrado de maquinaria y procesos diseñado para convertir maní crudo en mantequilla de maní envasada. Incluye varias unidades para asar., peladura, molienda, Mezcla, relleno, y embalaje. A menudo se le conoce como un sistema de producción de pasta de nueces o línea de procesamiento industrial de maní, Garantiza una producción en masa con altos estándares de calidad y seguridad..

3. Descripción general del mercado y tendencias de la demanda global

La industria de la mantequilla de maní está en auge, especialmente con el aumento de consumidores preocupados por la salud. Las tendencias del mercado incluyen:

- Demanda de mantequilla de maní orgánica y sin azúcar

- Creciente popularidad en Asia, África, y sudamerica

- Uso creciente en snacks proteicos, batidos, y recetas veganas

- La automatización y las líneas de producción rentables impulsan la expansión global

4. Componentes clave de una línea de producción de mantequilla de maní

- tostador de maní

- Transportador de enfriamiento

- peladora

- Máquina trituradora y homogeneizadora.

- Tanque de mezcla y mezcla

- Tanques de almacenamiento

- Unidades de desgasificación

- Pasteurizador o esterilizador

- Relleno, caza de focas, y máquinas etiquetadoras

- Sistemas de embalaje de final de línea

5. Máquina tostadora de maní: Fundación del desarrollo del sabor.

Tostar es esencial para el sabor., aroma, y desarrollo del color. Los sistemas de tostado comunes incluyen:

- Tostadores por lotes (para operaciones pequeñas y medianas)

- Tostadores de cinta continua (para producción de gran volumen)

- Rango de temperatura: 160–180 ° C

- Sistemas opcionales de tostado de aceite.

6. Sistema transportador de enfriamiento: Control de temperatura para una textura óptima

Después de asar, Los cacahuetes deben enfriarse rápidamente para evitar que se tuesten demasiado.. Característica de los transportadores de enfriamiento:

- Cinturones de malla de acero inoxidable.

- Sistemas de aire forzado

- Sensores de temperatura automatizados

7. Cazador de maní: Quitar las pieles rojas para lograr pureza

El pelado mejora el color y la vida útil.. Las máquinas pueden procesar:

- 200–1000 kg/h

- Eliminación de piel seca o húmeda

- Separación neumática de la piel

- Clasificador de granos opcional

8. Máquina trituradora de maní: Molienda fina y homogeneización

Este es el núcleo de la línea de pasta de maní. Las características incluyen:

- Molino coloidal o triturador de piedra

- Finura de molienda ajustable (50–100 micras)

- Emulsificación de alta velocidad (arriba a 2800 rpm)

- Piezas de contacto de acero inoxidable

9. Unidades de mezcla y licuado: Personalizando el sabor y la textura

La mezcla permite la integración de ingredientes.:

- Azúcar, sal, Miel, aceite de palma

- Cacao, proteína en polvo, vainilla

- Pueden ser mezcladores discontinuos o continuos.

- Equipado con camisa calefactora y agitador.

10. Tanques de almacenamiento y retención: Almacenamiento provisional higiénico

Se utiliza para contener la mantequilla de maní antes de llenarla.:

- Tanques encamisados para control de temperatura

- Agitadores para evitar el asentamiento

- Diseño compatible con CIP

11. Máquina desgasificadora al vacío: Mejora de la estabilidad del producto

Los sistemas de vacío eliminan las burbujas de aire para:

- Prevenir la oxidación

- Mejorar la viscosidad

- Extender la vida útil

12. Pasteurización y Esterilización: Garantizar la seguridad alimentaria

Dependiendo de las necesidades del mercado:

- Pasteurizador para procesamiento a 65–85°C

- Esterilizador UHT para productos no perecederos

- Monitoreo de temperatura y presión en línea

13. Máquinas de llenado y envasado: Del tarro al mercado

La mantequilla de maní final se vierte en recipientes.:

- Frasco, apretar la botella, bolsita, o balde

- Boquillas de llenado servoaccionadas

- Sistemas antigoteo y CIP

- Rendimiento: 10–100 contenedores/min

14. Etiquetado, Codificación, y equipo de sellado

Incluye:

- Selladores por inducción de calor

- Mangas retráctiles

- Codificación por inyección de tinta o láser para trazabilidad

15. Soluciones de final de línea: Paletizadores y sistemas de embalaje

Automatización de procesos de final de línea:

- Paletizado robotizado

- Envoltura retráctil

- Máquinas selladoras de cajas de cartón

16. Automatización en la fabricación de mantequilla de maní

- Sistemas de automatización basados en PLC

- Sensores IoT para monitoreo en tiempo real

- Control SCADA e informes de lotes.

17. Consideraciones de diseño industrial: Disposición, Flujo de trabajo, y espacio

- Diseño lineal o en forma de U

- Entrada de materia prima a salida de producto terminado.

- Espacio para mantenimiento y autorización de seguridad.

18. Personalización de la Línea de Producción de Pasta de Maní

- Capacidad: de 100 kg/h a 2,000 kg/hora

- Crujiente vs.. opciones suaves

- Adición de chocolate, almendra, sésamo

- Integración con líneas de tostado de frutos secos y snacks.

19. Complementos comunes: Mezcladores, Inyectores de sabor, Sistemas de trituración de nueces

- Mezcladores de cinta

- Alimentadores de sabor de tornillo

- Dosificadores de doble textura

- Tanques de vacío con doble camisa

20. Limpieza en el lugar (Titubear) Sistema: Mantener la higiene en la producción

- Totalmente automático o semiautomático

- Implica agua caliente, lavado alcalino, enjuague ácido

- Reduce el tiempo de inactividad y los costos laborales

21. Especificaciones Técnicas de Máquinas Clave

| Equipo | Capacidad | Fuerza | Material |

|---|---|---|---|

| Tostador | 100–1000 kg/h | 25–60 kilovatios | SS304/SS316 |

| Amoladora (molino coloide) | 100–2000 kg/h | 5–15 kilovatios | SS304, de grado alimenticio |

| Vara | 10–100 ppm | 3–8 kW | Controlado por PLC |

| Tanque mezclador | 200–2000 L | 2–10 kW | Con agitador |

22. Eficiencia energética y consideraciones ambientales

- Uso de sistemas de recuperación de calor.

- Tuberías y tanques aislados

- Materiales de embalaje reciclables.

23. Análisis de costos: CapEx y OpEx en la producción de mantequilla de maní

- Línea pequeña: $15,000 - $50,000

- linea media: $50,000 - $150,000

- Línea completamente automática: $200,000 - $1,000,000+

- El retorno de la inversión suele tardar entre 12 y 24 meses

24. Cumplimiento normativo y certificaciones de calidad alimentaria

- FDA, Ceñudo, ISO 22000, HACCP

- Buenas prácticas de fabricación (GMP)

- Sistemas de control y trazabilidad de alérgenos.

25. Medidas y estándares de control de calidad

- Muestreo y prueba (microbiología, viscosidad, gusto)

- Monitoreo de temperatura y pH en línea

- Detección de metales e inspección por rayos X.

26. Solución de problemas y mantenimiento de equipos de mantequilla de maní

- Fallas comunes: atasco, sobrecalentamiento del motor, molienda desigual

- Programas de mantenimiento preventivo

- Disponibilidad de kits de repuestos

27. Beneficios de invertir en una línea de producción de mantequilla de maní llave en mano

- Instalación más rápida

- Soporte técnico del proveedor

- Flujo de proceso optimizado

- Menor riesgo de que el equipo no coincida

28. Ampliar la producción: De la pequeña empresa a la fábrica

- Comenzando con tostadores por lotes y llenadoras manuales

- Escalado a molienda y empaque automático

- Entrada al mercado a través de nichos o canales de exportación.

29. Estudios de caso: Plantas procesadoras de mantequilla de maní exitosas

- Caso: Startup de mantequilla de maní orgánica en EE. UU.

- Caso B: Exportador mediano en Nigeria

- Caso C: Gran planta industrial en India

30. El futuro de las tecnologías de procesamiento de mantequilla de nueces

- Fábricas inteligentes con control de IA

- Sistemas de procesamiento de nueces múltiples

- Líneas de envasado totalmente robóticas

- Integración con sistemas ERP

31. Cómo iniciar un negocio de fabricación de mantequilla de maní

- Realizar estudios de mercado

- Elija la escala de producción adecuada

- Adquirir terrenos y servicios públicos.

- Compra la línea de equipos.

- Contratar y capacitar personal

- Cumplir con las normas de seguridad alimentaria.

32. Selección de proveedores: Evaluación de fabricantes de equipos

- Experiencia y opiniones de clientes.

- Certificaciones globales

- Disponibilidad de soporte local

- Capacidades de ingeniería personalizadas

33. Conclusión: Construcción de una planta rentable de mantequilla de maní

Una alta calidad línea de producción de mantequilla de maní es la columna vertebral de un exitoso negocio de fabricación de cremas de nueces. Del tostado al etiquetado, Cada etapa impacta la calidad y rentabilidad del producto.. Invertir en confiable, de grado alimenticio, y los sistemas automatizados garantizan el éxito y la escalabilidad a largo plazo.