Peanut butter has become a household favorite worldwide — from breakfast spreads to desserts and protein snacks. The growing demand for this nutritious product has opened a massive opportunity for food processors and entrepreneurs. For those looking to start or expand production, investing in a Commercial Peanut Butter Maker is the key to success.

This comprehensive guide explains everything you need to know about the commercial peanut butter machine, including how it works, the benefits, applications, technical parameters, and what to consider before buying one. Whether you operate a large processing plant or a small food factory, this article will help you choose the right industrial peanut butter grinder for your business.

1. What Is a Commercial Peanut Butter Maker?

A Commercial Peanut Butter Making Machine is a type of industrial food processing equipment used to grind roasted peanuts into smooth, creamy, or crunchy peanut butter. It uses a colloid mill or nut paste grinding mechanism to finely crush, mix, and emulsify the peanuts under high-speed shearing and friction.

Unlike small household blenders or grinders, a commercial peanut butter grinder is designed for continuous, high-volume production with consistent quality and stable performance. It can process hundreds of kilograms per hour, making it ideal for peanut butter factories, food companies, and large-scale peanut processing plants.

In addition to peanuts, the machine can process almonds, cashews, sesame seeds, sunflower seeds, cocoa beans, and other oily materials to make various types of nut butter and pastes.

2. How Does a Commercial Peanut Butter Machine Work?

The operation principle of the industrial peanut butter grinder is based on rotor-stator shearing technology. Here’s how the process works step by step:

- Feeding: Roasted and peeled peanuts are poured into the hopper at the top of the machine.

- Pre-Grinding: The peanuts enter the grinding chamber, where rotating and fixed grinding teeth shear and crush them.

- Fine Grinding: The paste is repeatedly processed until the desired smoothness is achieved.

- Cooling System: Some models include a water-cooling jacket to prevent overheating, ensuring that the peanut butter retains its natural flavor.

- Discharge: The finished peanut butter flows out through the outlet and can be transferred to mixing or filling equipment.

This efficient process allows the commercial peanut butter processing machine to produce a uniform, smooth paste without burning or losing flavor.

3. Key Components of the Machine

Every commercial peanut butter making equipment includes several main parts designed for durability and hygiene:

- Feeding Hopper: Holds roasted peanuts and feeds them into the grinding system.

- Grinding Chamber (Stator and Rotor): The heart of the machine that performs high-speed grinding.

- Cooling Jacket: Maintains temperature stability during long production runs.

- Motor: Provides powerful torque for continuous grinding.

- Discharge Outlet: Where the finished paste exits.

- Control Panel: Allows the operator to adjust speed and grinding fineness.

- Base Frame: Supports the entire structure and reduces vibration.

All contact surfaces are made from food-grade stainless steel (SUS304 or SUS316) to meet hygiene standards and prevent contamination.

4. Technical Specifications Example

| Model | Power (kW) | Capacity (kg/h) | Voltage (V) | Fineness (μm) | Weight (kg) | Material |

|---|---|---|---|---|---|---|

| PBM-80 | 4 | 70–200 | 220/380 | 50–200 | 150 | Stainless Steel 304 |

| PBM-110 | 7.5 | 100–300 | 380 | 50–200 | 220 | Stainless Steel 304 |

| PBM-130 | 11 | 300–500 | 380 | 50–200 | 260 | Stainless Steel 304 |

| PBM-180 | 18.5 | 500–800 | 380 | 50–200 | 400 | Stainless Steel 304 |

| PBM-240 | 37 | 800–1500 | 380 | 50–200 | 700 | Stainless Steel 304 |

Note: Custom sizes and power options are available for large-scale commercial peanut butter production lines.

5. Advantages of a Commercial Peanut Butter Maker

a. High Efficiency and Productivity

The industrial peanut butter grinder can process up to 1500 kg/h, drastically increasing productivity compared to manual grinding methods.

b. Consistent Quality

The machine ensures uniform grinding and smooth texture, producing peanut butter with consistent taste and appearance.

c. Hygienic and Durable Construction

Made from stainless steel, the commercial nut butter machine meets all food safety standards, ensuring cleanliness and corrosion resistance.

d. Versatility

Besides peanut butter, it can be used for almond butter, tahini, cashew butter, sesame paste, and even chili sauce or fruit jam.

e. Adjustable Fineness

The operator can control the grinding fineness to produce different textures — from creamy peanut butter to crunchy nut paste.

f. Energy-Efficient Design

Advanced motors and optimized structure reduce power consumption while maintaining excellent performance.

6. Applications in the Food Industry

The Commercial Peanut Butter Maker is widely used in various sectors, including:

- Food processing plants producing peanut and nut spreads

- Snack and confectionery factories

- Restaurants or central kitchens making sauces or pastes

- Nutritional supplement manufacturers

- Small and medium food enterprises

This machine can also be integrated into a complete peanut butter production line that includes roasting, peeling, grinding, mixing, cooling, and filling systems.

7. Installation and Operation Guide

Installation Steps:

- Place the machine on a stable surface and ensure it’s level.

- Connect the power source according to the machine’s voltage.

- Connect the cooling water inlet and outlet if the model has a cooling system.

- Check all bolts, wiring, and seals before startup.

Operation Procedure:

- Start the motor and allow it to run empty for 1–2 minutes.

- Slowly feed roasted peanuts into the hopper.

- Adjust the gap between the stator and rotor for the desired smoothness.

- Collect the peanut butter from the discharge port.

- After operation, clean the machine with warm water and dry all parts.

Safety Tips:

- Do not insert hands or tools into the hopper while running.

- Always cut off the power before cleaning or maintenance.

- Avoid grinding raw or unroasted peanuts as it can damage the machine.

8. Maintenance Tips for Long Service Life

To ensure optimal performance and long lifespan of your commercial peanut butter processing machine, follow these maintenance guidelines:

- Lubricate bearings regularly.

- Inspect the rotor and stator for wear after every 200 hours of use.

- Clean thoroughly after each shift to avoid residue buildup.

- Monitor motor temperature to prevent overheating.

- Replace worn seals immediately to maintain hygiene.

Routine maintenance not only prevents downtime but also extends the life of your automatic peanut butter maker.

9. How to Choose the Right Commercial Peanut Butter Grinder

When investing in a commercial peanut butter making equipment, consider these important factors:

- Production Capacity: Choose a model that matches your expected daily output.

- Grinding Fineness: Adjustable machines allow flexible product texture.

- Power and Voltage: Ensure compatibility with your factory’s power system.

- Material and Build Quality: Opt for food-grade stainless steel.

- Manufacturer Support: Look for a supplier offering spare parts, warranty, and technical training.

A trusted supplier like DT Food Machine can provide customized solutions for your production requirements and factory layout.

10. Business and Economic Benefits

Investing in an industrial peanut butter processing machine can yield strong profits due to the following reasons:

- High Market Demand: Peanut butter consumption is growing globally, driven by health trends.

- Low Raw Material Cost: Peanuts are inexpensive and readily available.

- Fast ROI: Many factories recover investment costs within 6–12 months.

- Brand Potential: You can produce your own peanut butter brand for domestic or export markets.

By using an efficient commercial nut butter machine, you can increase productivity, reduce labor costs, and improve profit margins.

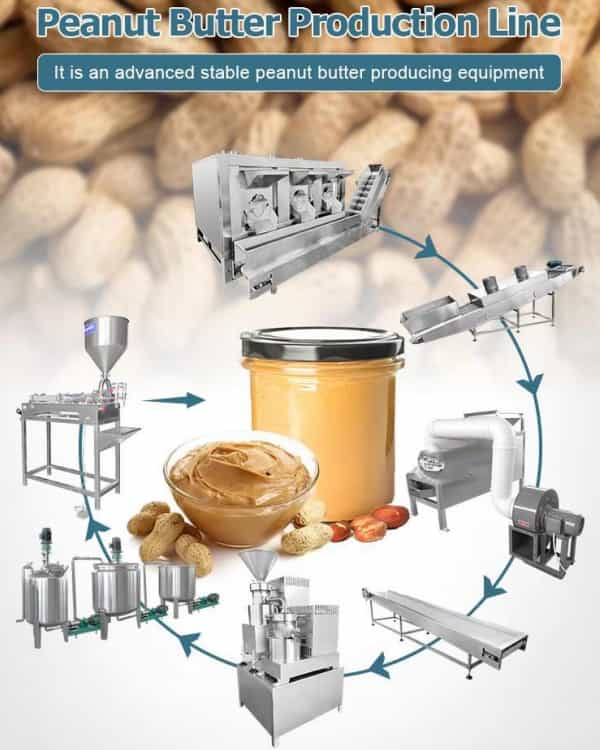

11. Integration into a Complete Peanut Butter Production Line

A Commercial Peanut Butter Making Machine is often the core component of a full processing system. A typical industrial peanut butter production line includes:

- Peanut Roasting Machine – for uniform roasting.

- Peanut Peeling Machine – to remove red skin.

- Elevator Conveyor – to transfer materials automatically.

- Grinding Machine – for peanut butter making.

- Mixing Tank – for blending sugar, salt, or flavor additives.

- Cooling Tank – to stabilize product texture.

- Filling Machine – for packaging jars or sachets.

DT Food Machine provides turnkey automatic peanut butter production lines tailored to different capacities and budgets.

12. Why Choose DT Food Machine

DT Food Machine is a professional manufacturer and supplier of Commercial Peanut Butter Maker and complete nut processing lines. Our machines are exported to more than 60 countries, trusted by clients for:

- High-quality stainless steel construction

- Precision grinding performance

- Customizable designs and capacities

- CE certification and strict quality control

- Global technical support and training

We aim to help customers achieve efficient, hygienic, and profitable peanut butter production.

13. Future Trends in Peanut Butter Manufacturing

The peanut butter industry is evolving toward automation, sustainability, and health-conscious products. The new generation of automatic peanut butter processing machines integrates:

- Energy-saving motors

- Intelligent temperature control systems

- Automated feeding and discharging

- Easy cleaning (CIP) designs

These innovations improve efficiency, reduce manual labor, and maintain high food safety standards — key advantages in modern peanut butter production.

14. Commercial Peanut Butter Maker

A Commercial Peanut Butter Maker is essential for any business aiming to produce high-quality peanut butter efficiently and safely. From small-scale processors to large food manufacturers, investing in a reliable industrial peanut butter grinder can significantly boost productivity, consistency, and profits.

By choosing an experienced supplier like DT Food Machine, you get not only a durable and efficient machine but also full technical guidance and customized production solutions.

Whether you’re producing creamy peanut butter, almond butter, or sesame paste, a commercial-grade machine will ensure your product stands out in the competitive food market.