Tomato puree making machine are essential equipment for food businesses that turn fresh tomatoes into smooth sauce or paste. These machines crush and refine tomatoes, separating skins and seeds to produce a uniform puree suitable for sauces, soups, and seasonings. In recent years the market for processed tomato products has been booming – driven by consumer demand for convenience, health benefits of tomatoes (rich in lycopene and vitamins), and a growing global food industry. As the global tomato processing industry surpassed 48.5 million tons in 2024 and is projected to grow at ~3% annually, small and mid-size producers are increasingly investing in reliable tomato puree machines. This guide covers everything you need to know – from how these machines work and the types available, to market trends, buying tips, and production line setup.

How tomato puree making machine Work

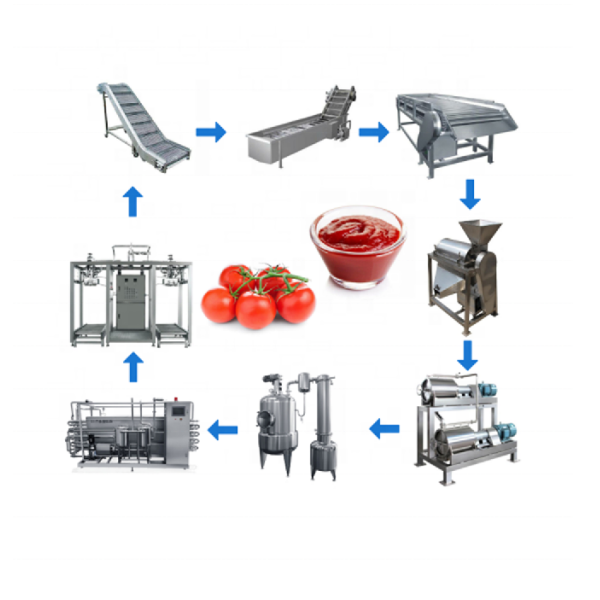

At their core, tomato puree making machines are high-speed mechanical blenders/pulpers that break down fresh tomatoes into smooth liquid pulp. For example, a typical machine uses multiple rotating stainless-steel blades to shred and cut the tomatoes into fine particles. The diagram below illustrates a common processing flow:

Figure: Typical tomato processing flowchart – key stages from raw tomatoes to final puree.

In practice, the process goes as follows: fresh tomatoes are first washed and sorted to remove debris and bad fruit. They then enter a crusher or hammer mill that smashes them into mash. Next, the mash is often heated slightly (in a hot break step) to inactivate enzymes, then sent to a pulping machine. This pulping unit typically consists of a fast-turning screw or paddles inside a perforated screen. The impeller forces the tomato mash against the screen, separating skin and seeds from the tomato juice and pulp. The finely filtered pulp (typically 0.4–0.6 mm in size) flows through as puree, while peels and seeds are discharged.

For very fine consistency, some operations use a colloid mill or homogenizer after pulping. A colloid mill has two steel plates (one fixed, one rotating) with a narrow gap. High-speed rotation shears and emulsifies the pulp, yielding an ultra-smooth puree. In summary, the combination of mechanical cutting, screening, and sometimes colloid milling ensures a lump-free tomato puree ready for cooking or concentration.

Types of tomato puree making machine

Tomato puree making machine come in various sizes and designs, from bench-top mini units to large industrial lines:

- Small Commercial Machines (100–1,000 kg/h): These tabletop or floor-standing pulpers/crushers serve cafes, restaurants, and small factories. They often use a simple blade cutter or fruit crusher design. For example, one model has ten sharp rotating blades and can process 600–800 kg/h, powered by a 2.2 kW motor. Its cutting thickness is adjustable by changing blade height, and the unit is usually made of food-grade stainless steel for hygiene. Such machines are portable and easy to clean, but handle only a few tons per day.

- Medium-Scale Machines (1–10 TPH): These lines are semi-automatic and handle 1–10 tons of tomatoes per hour. They include continuous conveyors, larger crushers (or crushing pumps), and double-stage pulping machines. In a typical mid-scale plant, tomatoes pass through an air-bubble washer and a sorting conveyor before reaching a hydraulic crusher or pulping unit. The pulper may have two beating stages for higher yield (~90%) and finer pulp. Some units also feature colloid mills for extra smoothness. For example, a Chinese supplier’s turnkey line has a 6 t/h throughput using a 220 kW system, producing ~17–20 tons of puree per day. These systems are built robustly (heavy steel frames, industrial gearboxes) and often include semi-automatic controls and pre-heating sections to ensure quality.

- Large-Scale Industrial Lines (>10 TPH): Major food factories use fully automated processing lines handling tens to hundreds of tons per day. These lines integrate flumes, elevators, heavy crushers, multi-effect vacuum evaporators, and aseptic fillers. For instance, CFT Food Machinery (Italy) offers lines capable of processing up to 3,000 tonnes per day. They emphasize energy efficiency – using electric evaporators and gentle heat treatment to preserve flavor. Similarly, Triowin (China) lists turnkey lines from 60 to 2,000 tons per day, complete with control rooms, PLC automation, and both hot-break and cold-break options. These high-end lines can tailor output to paste, ketchup, puree or juice, and often recover waste heat and water for sustainability.

Each type of machine shares common features: stainless steel construction (often SUS304/316L) for food safety, CIP capability, and efficient motors. However, the choice depends on scale and product: a small cottage plant needs only a simple pulper, while an industrial concern invests in multi-stage lines with concentration and packaging stations.

Key Technical Specifications tomato puree making machine

When evaluating tomato puree machines, pay attention to these technical specs:

- Capacity: Measured in kg or tons per hour. Small machines: hundreds of kg/h; medium: 1–10 T/h; large: 10–100+ T/h. E.g., the 600 kg/h pulper above vs. a 6 T/h industrial line. Capacity should match your processing volume to ensure efficiency.

- Power (kW): Motor size grows with capacity. The 600 kg/h unit uses just 2.2 kW, whereas the 6 T/h line requires 220 kW. Industrial lines often draw hundreds to thousands of kW to run crushers, pumps, evaporators, and motors simultaneously.

- Material of Construction: Must be food-grade and durable. Nearly all commercial units use SUS304 or 316L stainless steel for contact parts. This resists corrosion by acids and simplifies cleaning. Check that all hoses, screens, and fasteners are also stainless.

- Feed and Discharge Size: Smaller machines may accept whole or quartered tomatoes, whereas large crushers might require coarse chopping first. Discharge mesh size (how fine the pulp is) is often adjustable. High-quality puree machines can filter pulp to well under 1 mm particle size.

- Control and Automation: Many modern machines include PLC control panels for setting speeds, temperatures, and timings. Look for options like touchscreens, recipe memory, and even remote monitoring. For safety and ease, machines may have IP-rated controls and sensors.

- Utilities: Typical power requirements are 220/380 V, 50/60 Hz for electric motors. Large lines also need steam for preheating and evaporation and ample water (see [47]: 15–20 t water per hour for a 6 T/h line). Ensure your facility can supply and treat these.

- Mobility and Footprint: Small tabletop pulpers occupy about 1–2 m², while full lines need industrial space with conveyors, tanks, and support. Evaluate machine dimensions and whether it has wheels or is fixed.

Keeping these specs in mind will help you match a machine to your production goals. In general, larger-capacity machines cost more, but also provide better economies of scale.

Production Process Overview tomato puree making machine

A streamlined tomato puree production line typically follows several stages. Below is an overview of the key steps, referencing both standard industry practice and machine descriptions:

- Receiving & Conveying: Fresh tomatoes arrive by crate or truck. Large plants often use an hydraulic transport system or flume to unload and convey tomatoes into the factory. Automated dumpers can drop bins into water channels, separating floating ripe fruit from debris.

- Washing & Sorting: Tomatoes are washed in rotating brushes or bubble washers to remove dirt, leaves, and pesticides. Workers or optical sorters then remove rotten or damaged fruit on conveyor belts. Unwanted material is discarded via screw conveyors.

- Crushing/Crushing Pump: The clean tomatoes feed into a crusher or rotary pump. This machine tears fruit into coarse mash. It may use sharp blades or hammers to liberate juice from the flesh. The crushed mash is often pumped continuously to the next stage.

- Enzyme Inactivation (Preheating): To stabilize color and flavor, the tomato mash is briefly heated. Hot-break (85–100°C) inactivates pectic enzymes, yielding thicker paste, while cold-break (60–70°C) is used for juice/puree to preserve fresh taste. This is done in a tubular heat exchanger (preheater).

- Pulping & Refining: The heated mash enters the pulping machine (sometimes called a pulper or pulping finisher). In a double-stage pulper, a rotating rotor forces mash through a sieve, finely crushing fruit and filtering out skins and seeds. The result is a smooth, seed-free tomato puree. Colloid mills (as described earlier) may be used here for ultra-fine texture.

- Filtration: After pulping, any residual coarse particles pass through filters or screens. Sometimes a flotation step uses air bubbles to float away remaining skins.

- Concentration (Optional): If making tomato paste or a thicker puree, the pulp is sent to vacuum evaporators. These remove water under vacuum at low temperature, raising Brix (sugar content) up to 28–30% or more. Multi-effect, low-temperature evaporators (e.g. JBT’s low-profile evaporators) are common to minimize heat damage. The output is concentrated paste.

- Sterilization: Both puree and paste must be pasteurized or sterilized to ensure safety. This is often done in a tubular pasteurizer or aseptic flash heater, especially for aseptic packaging. High-viscosity paste may use scraped-surface heat exchangers or tube-in-tube sterilizers. Typical targets are F₀ values that achieve commercial sterility.

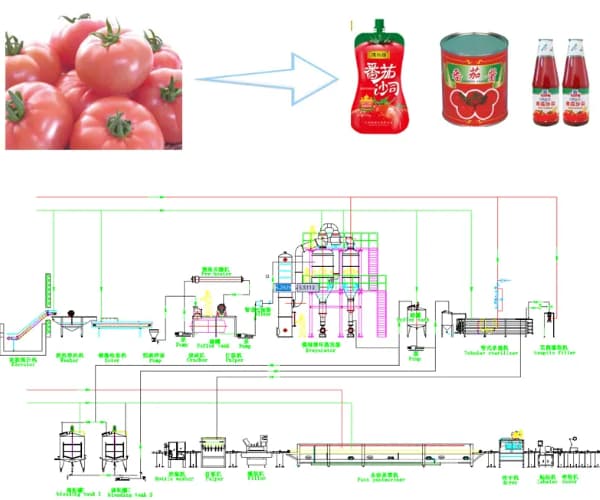

- Filling and Packaging: Finally, the tomato puree or paste is packed. Options include hot-filling into jars or bottles, filling into aseptic bags/drums (for bulk paste), and aseptic pouch or cup filling. Filling machines must match your packaging – e.g. a can filler for cans, or a bag filler for large volumes. After filling, containers are sealed, cooled if needed, and labeled. Modern lines often have robots and conveyors for packing cartons.

Each stage is usually linked by pumps and conveyors for continuous flow. Critical control points (Brix, pH, temperature) are monitored throughout. Proper layout ensures a linear “cold-to-hot” flow to prevent contamination. The Triowin line spec sheet notes that a good plant includes a control room to monitor each processing stage in real time. The embedded flowchart above gives a visual of these steps.

Latest Market Trends & Global Insights tomato puree making machine

The demand for processed tomato products (purees, sauces, pastes, juices) is rising worldwide. Convenience foods and health trends are major drivers. Convenience: modern consumers, especially younger generations, favor ready-to-use ingredients. Tomato sauce and puree enable quick meals (pasta sauce, soups) year-round. Health: Processed tomato products are rich in nutrients; in fact, heating increases lycopene availability. Manufacturers market low-salt, organic, non-GMO tomato products to appeal to health-conscious buyers.

Market research confirms robust growth. The global tomato processing market was valued around 48.5 million tons in 2024 and is expected to reach ~64.6 million tons by 2033 (≈3.2% CAGR). In dollar terms, reports (2024) put the market near $200+ billion with steady expansion. This is fueled by trends like farm-to-table and increased R&D for better shelf life.

Geographically, China, the USA, and Italy are the top tomato processors. In 2024 Italy processed about 5.3 million tons of industrial tomatoes, making it the world’s third-largest processor after China (fast-growing, +31% from 2023) and the U.S. Italy is known as the largest exporter of tomato products for final consumption (cans, sauces), but faces competition from cheaper imports. In fact, Italian industry groups have even petitioned to restrict Chinese tomato concentrate imports, noting that Chinese product can be “almost half” the price of domestic concentrate. This illustrates global supply chain pressures: many countries import bulk tomato paste/concentrate (often from China or Eastern Europe) to blend with local produce.

Overall, processors should stay alert to supply chain dynamics: tomato prices vary by season and region, and international trade policies (tariffs, origin labeling) can impact costs. On the upside, technological innovations (automation, sustainable energy) and niche products (organic, artisan sauces) offer new growth avenues.

Buying Guide: What to Consider Before Purchasing tomato puree making machine

Choosing the right tomato puree machine or production line is a critical investment. Here are key factors to evaluate:

- Capacity Needs: Estimate your throughput. A machine too large wastes energy; too small bottlenecks production. For example, a small restaurant might only need ~0.5–1 t/day (e.g. 600 kg/h pulper), whereas a mid-size plant may target 10–50 t/day. Check if equipment can be scaled or paralleled as you grow.

- End Product Specifications: Will you produce single-strength puree, concentrated paste, or specialty sauces? Make sure the machine meets your Brix target and texture. If you plan multiple products (puree vs paste vs ketchup), consider a flexible line or multiple lines.

- Machine Type & Technology: Decide on hot-break vs cold-break processing (affects viscosity and flavor). Some machines offer both modes. Also, choose between vertical (stacked blades) vs horizontal pulpers, or blade cutter vs colloid mill depending on desired fineness.

- Construction Quality: Look for reputable manufacturers using high-quality materials. Food-grade SUS304/316L stainless steel is a must (e.g. “made of stainless steel, durable, meets food hygiene”). Welds should be smooth, weld-free interior surfaces to prevent sludge traps. Frame and bearings should handle continuous operation.

- Automation & Control: Higher automation reduces labor but increases complexity. Check if the machine has CIP (clean-in-place) capability, PLC control, and safety features (e.g. interlocks, emergency stops). Machines with full automation and PLC interfaces (like those by JBT) can drastically cut operating costs.

- Energy and Water Usage: Efficiency matters. Modern evaporators (e.g. multi-effect, vacuum design) cut energy usage by up to 90%. Verify power, steam, and water requirements (see [47] for an example: 220 kW, 3.5–4.2 t/h steam, 15–20 t/h water for a 6 t/h line). Choose machines with energy recovery (heat exchangers, steam condensers) to lower costs.

- Brand and Service: Major brands like JBT (FoodTech), CFT (Italy), Alfa Laval (Sweden), and Chinese firms like Shanghai Beyond or Triowin each have strengths. Well-known brands often have better technical support and parts availability. For instance, JBT emphasizes robust evaporators and comprehensive after-sales service. Look for suppliers who offer installation assistance, training, and long warranties (e.g. 12-month warranty noted by Beyond).

- Price and Budget: Commercial paste lines can be expensive. A basic electric pulper might cost a few thousand USD, while a complete 5–40 TPH line can range from $50k to $500k or more. Always compare quotes carefully: a cheaper machine may have lower specs or shorter life. Factor in ROI: at typical profit margins of 5–20%, cutting equipment downtime and energy use pays off quickly in large-scale operations.

- Footprint and Integration: Ensure your plant has space for the machine and ancillary equipment (tanks, conveyors). Plan the layout so that the workflow is linear and hygienic. Many suppliers assist with turnkey design – e.g. machinehall.com offers turnkey plant planning from reception to packaging.

Factors Checklist: When evaluating a quote, consider product specs (capacity, output consistency), equipment durability (material, certifications), utilities (power, steam, water use), automation level (manual vs PLC, sensors), cost (machine + installation + training), and ongoing support. Also review references or case studies – reputable suppliers can often show videos or photos of existing installations (see example images below).

Figure: An industrial tomato pulping machine (feeding hopper and rotor visible) used in commercial processing. Such machines often feature heavy-duty motors and robust stainless-steel construction.

Price Ranges and ROI Analysis tomato puree making machine

Investment Ranges: Prices vary widely by scale. Small countertop or bench-top puree machines might range from $500 to $5,000, depending on build quality and country of origin. Larger semi-automatic units or small production lines (up to 1–2 TPH) can be $10k–$50k. Industrial-scale turnkey lines (10–40 TPH or more) often cost $100k–$1M+. As an example, one Chinese-made 6 t/h line is quoted at roughly 220 kW of power and packaged as a $50k–$500k turnkey unit. Always verify what’s included (machinery only vs. full installation, shipping, etc.).

Operating Costs & ROI: Running a tomato puree facility incurs costs for tomatoes (50–70% of total), energy (steam, electricity), labor, and packaging. Profit margins in this sector tend to be modest (often 5–20% net). Thus ROI depends on scale and efficiency. A highly efficient plant (low waste, high throughput) can pay back equipment within a few years, while a small line may take longer. For example, at a 10% margin, an annual revenue of $500k yields $50k profit – so a $100k machine would need ~2 years’ profit to pay off. Cutting costs (by automating or saving energy) and achieving premium pricing (organic or specialty products) can shorten ROI. Tools like ROI calculators or business models are helpful. Industry advice suggests careful business planning: multinationals report that large integrated players often spend $2–10 million on a modern processing plant, which implies a multi-year payback at scale. For small entrepreneurs, starting with a used or refurbished machine can reduce upfront cost.

Financing Tips: Inquire about supplier financing (e.g. JBT’s PRoCARE® financing) or local equipment loans for food projects. Factor in maintenance and spare parts: a reliable supplier should provide long-term parts availability and technical support.

Comparison of Popular Machines and Manufacturers tomato puree making machine

To help navigate options, here are comparison tables of machine models and leading brands.

Table 1: Sample Tomato Puree Machine Specifications

| Example Machine | Capacity | Power | Notes | References |

|---|---|---|---|---|

| Small Electric Pulping Unit | 600–800 kg/h | 2.2 kW | Benchtop unit for restaurant/canteen; stainless steel blades | dtfoodmachine.com |

| Shanghai Beyond 6 T/H Line | 6,000 kg/h | 220 kW | Industrial turnkey line; output ~17–20 t/day paste | dtfoodmachine.com |

| Triowin 60 t/d (2.5 T/H) Line | 2,500 kg/h | 83.8 kW | Large paste line (double-vacuum evaporator); ~60 t/day | dtfoodmachine.com |

(Capacities and power as reported by manufacturers; actual production depends on tomatoes’ Brix and line efficiency. Power for large lines may include auxiliary systems.)

Table 2: Key Tomato Processing Equipment Brands

| Manufacturer | Country | Key Products / Strengths | Notes / References |

|---|---|---|---|

| JBT FoodTech | USA / Global | Evaporators, aseptic fillers, pasteurizers, separators | Focus on low-temp, multi-effect evaporators and strong technical support |

| CFT Food Machinery | Italy | Complete paste/puree/sauce lines; large capacities | Italy’s industry leader since 1945, up to 3,000 t/day, energy-efficient designs |

| Alfa Laval | Sweden | Decanter centrifuges, thermal exchangers, separators | Specialist in sanitary separation (Foodec centrifuge) and thermal systems |

| DT Food Machine | China | Turnkey tomato/paste/puree lines (5–40 TPH) | Example: 6 T/h line producing ~20 t/day; offers both semi-auto and full lines |

| DT Food Machine | China | Customized processing lines (60–2,000 t/d) | Emphasizes advanced automation and quality control |

These brands are a starting point. Each has a global presence: JBT (with FranRica and Avure brands) and CFT have long histories with thousands of installationscft-group.com. Chinese manufacturers like Beyond, Triowin, and others (e.g. Focus Machinery, LINMFG) offer cost-competitive turnkey plants, often with European technology partnerships. When reviewing vendors, compare warranty terms, local service, and references (e.g. customer visits).

Setting Up a Tomato Puree Production Line

Beyond the machine itself, setting up a full production line involves several stages and layout considerations:

- Raw Material Supply: Secure a reliable source of ripe tomatoes. Processing tomatoes (lower moisture, higher solids) are ideal. Plan for seasonal variations – contracts with local growers or import plans. Consider building a holding facility or cold storage if tomatoes arrive ahead of processing.

- Factory Layout: Design a unidirectional flow: raw → wash → crush → puree → package. Avoid backflow. Typical lines use gravity and conveyors to move product (as in the flowchart). On one wall you might have washing, sorting, and elevating; next to it crushing and pulping; then concentration/sterilizing in the center; and packaging at the far end. Utilities (steam boiler, chiller, CIP station) are usually adjacent to processing areas.

Figure: A modern tomato processing plant. Large-scale facilities often include conveyors, vacuum evaporators (with steam pipes), and storage tanks as seen here. Efficient layout and robust equipment (all stainless steel) are critical for smooth operation.

- Equipment Integration: Include holding tanks (with agitators) for intermediate pulp or puree. Install pumps and pipes (usually stainless or food-grade plastic) sized for high flow. An example layout element is a pasteurizer in a skid. Ensure safety features: walkways, railings, and emergency exits are required.

- Quality & Safety: Implement quality checks at key points. Measure Brix and pH of the puree; target industry norms (e.g. 28–30% Brix for paste). Monitor temperatures in preheater and sterilizer to meet pasteurization standards. Install metal detectors or sieve filters for foreign objects. Maintain a strict Clean-In-Place (CIP) routine – every pump and tank can be cleaned automatically with caustic and sanitizer between batches.

- Utilities & Waste: Plan for adequate utilities:

- Water: for washing and processing – lines may recycle wash water (Triowin’s 60 t/d line uses 7.1 t/h of water).

- Steam: for heating and sterilizing – a boiler sized for peak demand is needed (e.g. 3–5 t/h steam for medium plant).

- Electricity: heavy lines may require hundreds of kW.

- Air: compressors for pneumatic valves.

- Waste handling: skins/seeds (pomace) can be composted or fed to livestock. Effluent (water from washing) must be treated per regulations.

- Automation & Control: Install a central control panel or SCADA system to manage valves, sensors, and robots. Triowin notes that a control room can reveal daily output at a glance. Label instruments and use food-safe Siemens/Schneider PLCs if possible. Connectivity allows remote support.

- Packaging: Decide packaging in advance. For tomato puree, common formats are glass bottles, squeezable pouches, plastic jars, or metal cans. The chosen format affects filling machines: e.g., a volumetric filling head for glass jars or an aseptic bag filler. Allocate space for filling, capping, labeling, and case packing. Keep this downstream of a pasteurizer or under aseptic conditions, depending on product type.

- Layout Example: A small plant may have just a pulper and pasteurizer with a manual filler. A larger one will have conveyors transporting peeled tomatoes into a crusher, pipes to a pulper/finisher, then to a multi-effect evaporator in an adjacent room, finally to an aseptic filler under a clean hood. In any case, ensure good lighting, ventilation (to remove cooking odors), and accessibility for maintenance.

By carefully planning the line (sometimes with supplier assistance for turnkey projects), one can build an efficient, high-quality tomato puree plant. Always conduct a trial run of the full line before commercial launch.

Advice & Best Practices tomato puree making machine

- Raw Tomato Variety: Use appropriate tomato varieties (industrial tomatoes or vine-ripened). Inconsistent raw quality yields inconsistent puree. Implement a quick Brix check on incoming fruit and sort out underripe tomatoes.

- Cleaning & Hygiene: Sanitation is paramount in tomato processing. After each campaign or major run, dismantle and clean pulp sieves, screens, and all tanks. Many machines allow quick-release blades for cleaning. Ensure workers follow GMP (Good Manufacturing Practices) and wear protective gear.

- Waste Minimization: Strive for high juice/pulp yield. Good machines achieve ~90% juice yield. Use by-products (peels, seeds) commercially (e.g. as livestock feed or biomass fuel) to improve overall ROI.

- Quality Control: Regularly test product for Brix, acidity, microbial counts, and color. Consistency matters: customers expect a standard taste and viscosity. If producing multiple products (sauce vs puree), maintain separate lines or thorough cleaning between runs to avoid flavor carryover.

- Maintenance: Create a preventive maintenance schedule. Lubricate motors/bearings as recommended, check blade sharpness, and inspect seals to prevent leaks. Keep spare parts (belts, bearings, sensors) in stock to avoid downtime.

- Scaling Up: If starting small, consider modular machines that can grow with demand. Some suppliers allow adding another pulper or evaporator stage later. Alternatively, plan expansion by reserving space for additional equipment.

- Staff Training: Even an “automatic” line needs skilled operators. Learn the ins and outs of your equipment. Many OEMs (Original Equipment Manufacturers) provide training. Understanding how machine parameters (speed, temperature) affect the product is key to troubleshooting.

- Regulations: Check food safety regulations (e.g. FDA in the U.S., EFSA in Europe) for tomato products. Labels must reflect ingredients and possible allergens. Environmental permits may be needed for effluent discharge or emissions.

- Market Development: Finally, think beyond puree. Once your line is running, you can diversify into tomato ketchup, sauces, or juice, increasing asset utilization. For example, concentrated paste in aseptic drums can later be reconstituted or used by other food plants.

By focusing on equipment reliability, process control, and market needs, even small enterprises can tap into the lucrative world of tomato processing. As one manufacturer notes, a well-designed line “can produce first-class end-products while saving time and eliminating unnecessary costs”