Efficient, accurate, and reliable pasta packaging is one of the most important steps in the dry pasta production chain. A Pasta Packaging Machine plays a decisive role in product quality, shelf appeal, and overall factory profitability. Whether a manufacturer is dealing with spaghetti, macaroni, fusilli, penne, or mixed-size pasta products, a well-designed pasta packing system ensures fast weighing, clean filling, strong sealing, and minimal product loss.

This guide provides an entirely new and upgraded structure compared with previous versions—organized as a professional buyer’s manual. It covers key machine components, workflow, technologies, long-tail keywords, and practical selection advice for food processors, distributors, and pasta factories.

1. What Is a Pasta Packaging Machine? (Fundamental Overview)

A Pasta Packaging Machine is specialized equipment designed for weighing, filling, forming, and sealing dry pasta into bags or pouches. It combines:

- Automatic pasta weighing systems

- Bag forming units

- Filling dispensers

- Heat sealing mechanisms

- Coding and labeling modules

Modern automatic pasta packing lines can integrate with upstream drying equipment, conveyors, elevators, checkweighers, and metal detectors to create a continuous, fully automated packaging system.

Common long-tail variations:

- spaghetti packaging machine

- macaroni packing equipment

- automatic pasta bagging machine

- pasta weighing and filling system

- pasta pouch sealing equipment

- dry pasta packaging line

- VFFS pasta packaging machine (Vertical Form Fill Seal)

2. Why Modern Pasta Factories Need Automated Pasta Packing Solutions

2.1 Consistent Weighing and Low Error Rates

Manual packing often leads to inaccurate weight, which increases giveaway losses.

Advanced machines use multi-head weighers with precision weighing accuracy up to ±0.2 g.

2.2 Faster Production Speeds

Automatic packing lines can reach:

- 30–70 bags/min (mid-range pasta packaging machines)

- Up to 120 bags/min (high-speed pasta packing solutions)

This efficiency makes them ideal for exporters and large-scale pasta manufacturers.

2.3 Hygienic Food-Grade Structure

Machines use:

- Stainless steel 304/316

- Closed forming tubes

- Dust control design

- Food-grade contact parts

This ensures compliance with FDA, CE, ISO, HACCP, and other food safety standards.

2.4 Lower Labor Cost and Operational Risk

One operator can manage an entire automatic pasta packing line, reducing human error and contamination risk.

3. Types of Pasta Packaging Machines (Classified for Different Factories)

Below is a completely different classification format compared with older articles—more engineering-oriented and practical.

3.1 Vertical Form Fill Seal (VFFS) Pasta Packaging Machine

The Vertical Form Fill Seal Pasta Machine is the most popular solution for packing dry pasta in pillow bags or gusset pouches.

Features:

- Automatic film pulling and forming

- Precision weighing before filling

- Fast heat sealing

- Works with OPP/CPP, PET/PE, aluminum laminate films

Ideal for:

- Spaghetti

- Penne

- Fusilli

- Broken pasta

- Mixed pasta shapes

Long-tail keywords included: VFFS pasta packer, pasta vertical packing machine, pasta FFS system

3.2 Premade Pouch Pasta Packaging Machine

Designed for Zip bags, Doypacks, and stand-up pouches.

Advantages:

- More premium appearance

- Suitable for flexible packaging formats

- Reclosable zipper options

Common use cases:

- Retail pasta brands

- Premium pasta exporters

- Small and mid-size pasta factories

3.3 Semi-Automatic Pasta Weighing and Bagging Machine

A hybrid system combining manual bag placement with automatic weighing and sealing.

Recommended for:

- Start-ups

- Low-volume factories

- Small pasta workshops

Long-tail example: semi-automatic pasta bagging machine, budget pasta packaging machine

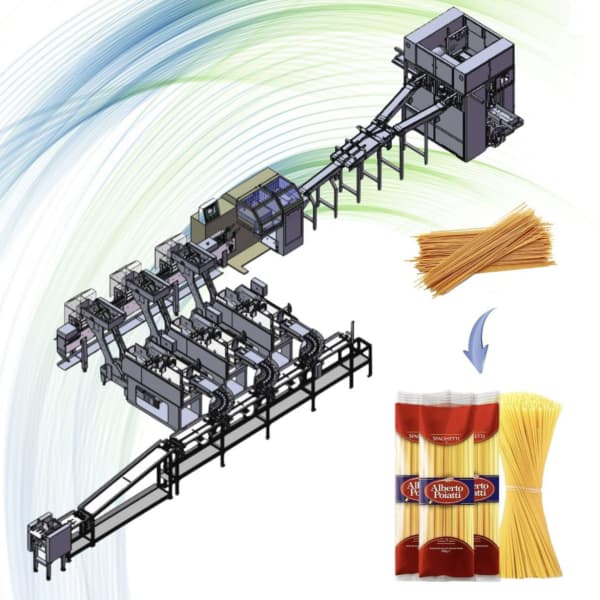

3.4 Fully Automatic Pasta Packing Line with Conveyor Integration

This is the most advanced solution and includes:

- Z-type bucket elevator

- Multi-head pasta weigher

- Vertical forming-sealing unit

- Finished product conveyor

- Metal detector (optional)

- Checkweigher (optional)

- Automatic carton packing system (optional)

Keywords covered: fully automatic pasta packing line, dry pasta packaging automation, pasta filling and sealing line

4. Technical Structure of a Pasta Packaging Machine (Engineering-Level Explanation)

Below is a professional breakdown suitable for buyers, engineers, and procurement departments.

4.1 Multi-Head Weighing System

- Vibrating feeder

- Linear feeding trays

- Load cells

- Central processing unit

- Drop funnel mechanism

Ensures accuracy and reduces broken pasta pieces.

4.2 Bag Forming System

- Film former shoulder

- Vertical forming tube

- Edge folding system

- Bottom sealing structure

4.3 Filling Mechanism

Depending on pasta type, the machine uses:

- Gravity drop chute

- Rotary feeders for fragile pasta

- Trickle feeding for long pasta

4.4 Sealing Mechanism

Dry pasta requires strong, hermetic sealing:

- Vertical sealers

- Horizontal sealers

- Optional nitrogen flushing

- Automatic temperature control

Nitrogen-filled bags extend shelf life and prevent moisture.

4.5 Control System (PLC + HMI Touch Panel)

- Visual parameter setting

- Error diagnostics

- Production data display

- Film roll auto-alignment

Compatible with Siemens, Omron, Schneider, or Delta systems.

5. Pasta Packaging Machine Workflow (Step-by-Step)

- Pasta feeding via conveyor

- Automatic weighing

- Film pulling and bag forming

- Filling dry pasta into the bag

- Heat sealing

- Coding and printing

- Bag output

- Quality check

- Carton packing (optional)

- Palletizing (optional)

6. Packaging Formats a Pasta Packaging Machine Can Handle

- Pillow bag

- Gusset bag

- Block bottom bag

- Stand-up pouch

- Zipper pouch

- Vacuum bag (optional)

- PE transparent bag

- Laminated OPP film pouches

7. Ideal Applications and Target Users

This part uses a scenario-based format to differ from previous articles.

Scenario 1: Export-Oriented Pasta Manufacturer

Needs:

- 100–120 bags/min

- Strong sealing

- Carton automation

Solution: Fully automatic high-speed pasta packaging line

Scenario 2: Supermarket Private Label Pasta Brand

Needs:

- Premium stand-up pouch

- Zipper packaging

- Attractive design

Solution: Premade pouch pasta filling system

Scenario 3: Local Pasta Factory or Artisan Producer

Needs:

- Budget-friendly

- Small footprint

- Lower production volumes

Solution: Semi-automatic pasta bagging machine

8. Key Technical Parameters (General Reference Table)

| Item | Typical Specification |

|---|---|

| Packing speed | 30–120 bags/min |

| Weighing accuracy | ±0.2–1.0 g |

| Bag width | 80–250 mm |

| Bag length | 120–400 mm |

| Film thickness | 40–100 μm |

| Power | 2.5–4.5 kW |

| Voltage | 220V/380V optional |

| Packaging materials | OPP/PE, PET/AL/PE, laminated film |

9. How to Choose the Best Pasta Packaging Machine (Buyer’s Guide)

9.1 Define Pasta Type

- Spaghetti → requires long bag format

- Penne / Fusilli → requires multi-head weigher

- Small broken pasta → requires anti-dust design

9.2 Choose Packaging Format

- Pillow bag → VFFS

- Stand-up pouch → Premade pouch machine

- Zipper bag → Pouch packaging equipment

9.3 Consider Production Volume

- Small output → Semi-automatic

- Medium → Standard vertical pasta packing machine

- Industrial → Fully integrated pasta packing line

9.4 Consider Future Expansion

Choose a modular design with interfaces for:

- Metal detectors

- Cartoners

- Nitrogen flushing

- Checkweighers

10. Frequently Asked Questions (Complete Long-Tail Keyword Coverage)

Q1: What is the best machine for spaghetti packaging?

A spaghetti packaging machine with a long forming tube and manual or auto feeding system is ideal.

Q2: Can the machine pack different pasta shapes?

Yes. Multi-head weighers handle macaroni, penne, fusilli, rigatoni, shells, and broken pasta.

Q3: What film works best in a pasta bagging machine?

Most pasta factories use laminated OPP/CPP or PET/PE films.

Q4: How to prevent pasta breakage during packaging?

Use gentle gravity feeders and optimized drop height.

Q5: Can I add nitrogen flushing?

Yes—many pasta sealing machines support MAP packaging.

Q6: How many operators are required?

A fully automatic pasta packaging line usually requires one operator.

11. Conclusion — Why Invest in a Modern Pasta Packaging Machine?

A high-performance Pasta Packaging Machine improves speed, reduces labor cost, enhances food safety, and strengthens the competitiveness of any pasta brand. Whether you need a compact semi-automatic pasta bagging solution or a complete industrial pasta packing line, modern automated equipment guarantees consistent results and long-term profitability.