Dalam industri pencuci mulut hari ini, Cones wafer rangup telah menjadi jiwa setiap ais krim. Dari kilang ais krim terbesar di dunia ke kedai gelato butik, Satu peralatan secara senyap -senyap memacu kejayaan ini: The Pembuat Wafer Cone. Mesin ini, tepat namun kreatif, Membolehkan pengeluar untuk mengubah bahan -bahan mudah -ar, gula, dan minyak -ke dalam kerucut yang sempurna yang menentukan gigitan pertama pelanggan.

Walaupun pelanggan menikmati selera, Pemilik perniagaan memahami bahawa kunci untuk rasa dan kualiti yang konsisten terletak pada mesin itu sendiri. Memilih hak mesin membuat wafer kerucut bukan sahaja keputusan teknikal tetapi pelaburan strategik dalam kecekapan, kualiti, dan reputasi jenama.

Teknologi di belakang pembuat kerucut wafer

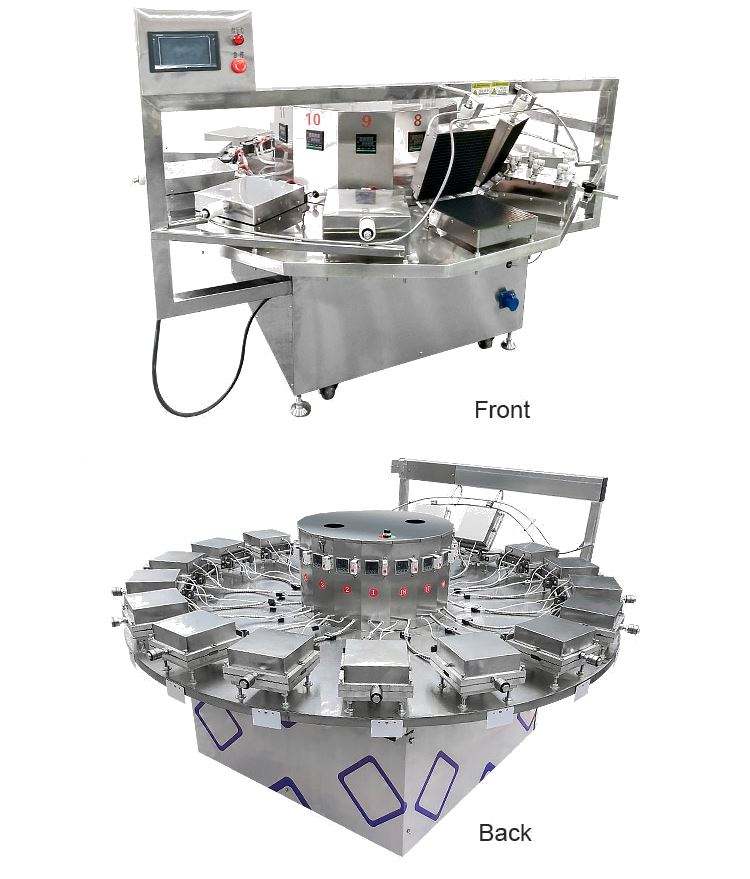

Tidak seperti besi wafel biasa atau akhbar kerucut penggunaan rumah, seorang profesional Pembuat Kon Wafer Industri Mengintegrasikan mekanikal, haba, dan sistem kawalan digital untuk mengendalikan pengeluaran berskala besar. Di dalam mesin, Kawalan suhu yang tepat dan rolling automatik Pastikan setiap kerucut mempunyai warna keemasan yang sama, Crispness, dan tekstur.

Proses pengeluaran bermula dengan adunan yang dirumus khas -bercampur dalam tangki sehingga licin. Adunan kemudiannya disimpan secara merata ke plat penaik panas, membentuk lembaran nipis. Dalam beberapa saat, Lembaran itu dilancarkan ke dalam bentuk kerucut oleh Unit Rolling Cone, disejukkan secara semula jadi di penghantar, dan akhirnya dilepaskan untuk pembungkusan.

Keseluruhan prosesnya pantas, automatik, dan sangat konsisten. Bagi pengeluar yang menghasilkan ribuan kon setiap hari, Automasi ini penting untuk memenuhi permintaan pasaran sambil mengekalkan kualiti seragam.

Mesin kon wafer automatik: Inovasi untuk kecekapan

The mesin kon wafer automatik mewakili evolusi penaik kerucut tradisional. Model manual yang lebih lama diperlukan pekerja untuk mencurahkan adunan dan menggulung setiap kon secara individu-proses intensif buruh. Sistem automatik moden, Walau bagaimanapun, boleh menghasilkan sehingga 10,000 kerucut sejam dengan pengawasan yang minimum.

Setiap acuan baking dibuka dan ditutup secara berirama, membentuk berpuluh -puluh kon secara serentak. The Panel Kawalan skrin sentuh PLC membolehkan pengendali menetapkan suhu penaik, kelajuan putaran, dan saiz kerucut dengan ketepatan. Sistem pemanasan gas atau elektrik boleh dipilih berdasarkan keperluan pengeluaran.

Inovasi ini bukan sahaja meningkatkan kelajuan tetapi juga memastikan konsistensi yang lebih baik, yang penting untuk jenama ais krim yang bergantung kepada keseragaman produk.

Ais krim membuat mesin vs. Mesin Waffle Cone

Ramai pelanggan tertanya -tanya tentang perbezaan antara a Pembuat Wafer Cone dan a pembuat kon wafel. Walaupun kedua -duanya menghasilkan kerucut ais krim, Mereka melayani pelbagai tujuan dan pasaran.

A Wafer Cone nipis, segar, dan cahaya. Ia pecah dengan masalah yang memuaskan dan sesuai untuk berskala besar, Pengeluaran kos efektif. Itu kerucut yang anda dapati di pasar raya, mesin layan diri, dan jenama ais krim makanan segera.

A Waffle Cone, Sebaliknya, lebih tebal, lebih manis, dan sering dibuat segar di kedai. Corak dan caramelized saman rasa premium. Mesin seperti mesin penaik kerucut wafel atau Pembuat Sugar Cone beroperasi pada suhu yang sedikit lebih rendah dan mengendalikan adunan padat.

Dengan kata lain:

- Wafer Cone = Pengeluaran Massa Perindustrian, kos rendah setiap bahagian.

- Waffle Cone = Persembahan Artisanal, Titik harga yang lebih tinggi.

Memahami perbezaan ini membantu pelabur memilih jentera yang tepat untuk pasaran sasaran mereka.

Peranan barisan pengeluaran wafer cone

Untuk kilang-kilang berskala besar, Mesin tunggal sering tidak mencukupi. Di sinilah a Barisan Pengeluaran Kon Wafer masuk.

Sistem automatik ini menggabungkan beberapa mesin yang saling berkaitan:

- Tangki pengadun dan penyimpanan adunan - Menyediakan dan memberi makan adunan secara automatik.

- Wafer Baking Oven - Mengandungi berpuluh -puluh acuan untuk baking berterusan.

- Mesin rolling cone - menggulung setiap lembaran yang dibakar ke dalam kerucut.

- Penghantar Penyejuk - menstabilkan tekstur sebelum pembungkusan.

- Stacker dan kaunter - Mengatur kerucut ke dalam kelompok untuk membungkus.

Hasilnya adalah proses yang diperkemas yang mampu menghasilkan 24/7, menyampaikan ribuan kerucut sempurna sejam dengan input manusia yang minimum.

Pengeluar suka Mesin Makanan DT Reka bentuk garis modular, membolehkan pelanggan memulakan kecil dan mengembangkan kapasiti apabila perniagaan berkembang.

Ciri -ciri Pembuat Kon Wafer Commercial Ciri -ciri yang penting

Semasa membeli a Pembuat Kon Wafer Commercial, Beberapa spesifikasi utama menentukan prestasi dan ROI.

1. Pembinaan dan ketahanan

Struktur keluli tahan karat gred makanan memastikan kebersihan dan rintangan kakisan. Acuan aloi besi atau aluminium yang ditempah mengekalkan haba secara merata.

2. Pilihan sumber tenaga

Pemanasan elektrik dan gas disediakan. Model gas memanaskan lebih cepat dan sesuai dengan persekitaran output tinggi, Walaupun sistem elektrik lebih bersih dan lebih mudah dipasang di dalam rumah.

3. Kawalan suhu dan masa

Thermostats Digital dan Sistem PLC menjamin penaik yang tepat-mencegah kerucut yang terlalu besar atau kurang matang.

4. Bentuk dan saiz kerucut yang disesuaikan

Dari kerucut bersaiz kecil (50 mm) ke kerucut gaya wafel jumbo (115 mm), acuan boleh disesuaikan untuk bentuk, diameter, dan corak.

5. Sistem keselamatan

Butang berhenti kecemasan, perlindungan beban, dan peminat penyejukan automatik menjadikan persekitaran pengeluaran selamat untuk pengendali.

Tinjauan Teknikal Mesin Wafer Cone Industri

Perindustrian biasa Mesin penaik kerucut wafer Termasuk 24-60 pasang acuan yang diatur dalam ketuhar berputar. Setiap pasangan beroperasi secara automatik: Adunan dituangkan, dibakar, dan dilancarkan dalam gelung yang berterusan.

| Parameter | Spesifikasi |

|---|---|

| Model | DT-WF800 |

| Voltan | 380V / 50Hz |

| kuasa | 12 - 18 kW |

| Kapasiti output | 5,000-10,000 kon/jam |

| Sumber pemanasan | Gas atau elektrik |

| Saiz kerucut | 60-115 mm |

| Sistem kawalan | PLC Touchscreen |

| Berat | 1,500 - 2,000 kg |

| Bahan | Keluli tahan karat + Acuan besi tuang |

| Jaminan | 12 bulan |

Persediaan ini membolehkan waktu pengeluaran yang panjang, penyelenggaraan yang rendah, dan kualiti yang konsisten, menjadikannya tulang belakang banyak kilang ais krim di seluruh dunia.

Kecekapan tenaga dan pertimbangan kos

Kos tenaga memainkan peranan besar dalam keuntungan jangka panjang pengeluaran kon. Moden Pembuat Wafer Cone dengan pemulihan haba pintar dan penebat dapat mengurangkan penggunaan tenaga sehingga sehingga 20%. Model gas sering memberikan kos operasi yang lebih rendah, terutamanya di kawasan dengan harga elektrik yang tinggi.

Harga profesional Mesin Wafer Cone berbeza secara meluas:

- Model manual peringkat kemasukan: Sekitar USD $ 500- $ 1,000

- Unit separa automatik: USD $ 3,000- $ 5,000

- Garisan kon wafer sepenuhnya automatik: USD $ 10,000- $ 50,000+

Walaupun pelaburan awal mungkin kelihatan tinggi, Kos buruh yang dikurangkan dan peningkatan output sering membolehkan perniagaan memulihkan pelaburan mereka dalam satu atau dua musim pengeluaran.

Petua Penyelenggaraan untuk Mesin Kon Wafer yang Berpanjangan

Menjaga mesin anda bersih dan diselenggarakan dengan baik memastikan kebolehpercayaan dan keselamatan. Selepas setiap pengeluaran dijalankan, Lap pembakar acuan dengan kain yang tidak kasar dan keluarkan sisa adunan. Sekali seminggu, Periksa bahagian mekanikal dan gunakan pelincir gred makanan untuk bergerak komponen.

Elakkan menggunakan alat tajam yang boleh menggaru plat. Penentukuran harus diperiksa setiap bulan untuk memastikan pemanasan walaupun. Banyak mesin moden dari Mesin Makanan DT Datang dengan sistem diagnosis diri yang memaparkan makluman jika suhu atau kelajuan putaran menyimpang dari julat pratetap.

Pasaran global untuk pembuat wafer kon

Apabila penggunaan ais krim global meningkat -terutamanya di Asia, Timur Tengah, dan Amerika Latin - pasaran untuk Mesin Kon Wafer Automatik terus berkembang. Pengeluar tempatan melabur dalam jentera untuk memenuhi permintaan domestik yang semakin meningkat daripada mengimport kon dari luar negara.

Penambahbaikan teknologi, seperti Kawalan suhu yang didorong oleh AI dan pembakar tenaga yang cekap, menjadikan pengeluaran lebih lestari. Sementara itu, Pilihan penyesuaian seperti penjenamaan pada kerucut atau reka bentuk kelebihan yang berbeza -pengeluar HELP membezakan produk mereka.

Mengapa Memilih Mesin Makanan DT untuk Peralatan Wafer Cone Anda

Semasa memilih rakan kongsi untuk barisan pengeluaran kerucut anda, pengalaman dan perkara sokongan. Mesin Makanan DT menonjol sebagai salah satu pengeluar yang paling dipercayai Pembuat Wafer Cone dan Mesin Waffle Cone di China, mengeksport ke lebih daripada 60 negara.

Syarikat menawarkan:

- Acuan kerucut yang direka khas untuk bentuk dan kapasiti yang berbeza.

- Barisan pengeluaran turnkey wafer kerucut.

- CE dan mesin yang disahkan ISO dengan sistem penjimatan tenaga.

- Perkhidmatan selepas jualan yang komprehensif, termasuk latihan pemasangan dan bekalan alat ganti.

Falsafah Mesin Makanan DT Mudah: membina mesin yang menghasilkan kualiti dan konsistensi setiap masa.

Trend masa depan dalam pengeluaran kerucut wafer

Automasi dan digitalisasi mendefinisikan era pemprosesan makanan seterusnya. Masa depan Mesin penaik kerucut wafer akan menggunakan sensor pintar untuk mengawal tahap kelembapan, Laraskan suhu penaik dalam masa nyata, dan bahkan meramalkan keperluan penyelenggaraan sebelum kerosakan berlaku.

Kemapanan adalah pembakar gas yang mesra-sama dengan tumpuan, Pembungkusan yang boleh dikitar semula, dan mengurangkan penggunaan tenaga menjadi faktor utama bagi pembeli antarabangsa.

Sebagai rantai pencuci mulut global berkembang, permintaan untuk dipercayai dan cekap mesin membuat ais krim akan terus meningkat, membuat pelaburan awal dalam peralatan canggih langkah strategik.

Bina perniagaan ais krim yang menguntungkan dengan mesin yang betul

A Pembuat Wafer Cone lebih daripada sekadar peralatan -itu adalah asas bagi setiap jenama ais krim yang berjaya. Dari aroma kerucut yang baru dibakar ke gigitan segar yang menggembirakan pelanggan, Semuanya bermula dengan ketepatan dan prestasi mesin anda.

Dengan memilih model yang betul, mengekalkannya dengan betul, dan bekerja dengan pembekal yang dipercayai seperti Mesin Makanan DT, anda boleh mencapai output yang tinggi, kualiti yang konsisten, dan keuntungan yang kukuh dalam perniagaan pengeluaran kerucut anda.