When customers walk into your ice cream shop, they’re not just craving sweetness—they’re seeking an experience. The scent of freshly baked waffle cones, the crunch beneath a creamy scoop, the warmth of something made-to-order. Энэ бол А арилжааны ice cream waffle cone maker doesn’t just fill a need—it creates a competitive edge.

What Makes a Commercial Waffle Cone Machine Different from Domestic Units?

Many new entrants in the food industry assume they can get by with a home-style cone maker, but that’s a critical operational misstep.

Key differences include:

| Өвөрмөц | Domestic Waffle Iron | Commercial Cone Maker |

|---|---|---|

| Гаралтын хүчин чадал | 1–2 cones per 5–7 mins | 60–120 cones per hour |

| Duty Cycle | Intermittent | Үргэлжилсэн |

| Plate Material | Cast aluminum | Nonstick-coated cast iron or food-grade stainless steel |

| Temperature Recovery | Удаан | Rapid heating core with PID control |

Commercial units are designed for high throughput without sacrificing uniformity, ensuring that every cone maintains consistent golden hue, даавуу, and pliability for rolling.

“We upgraded from a household maker to a double-plate Krampouz, and instantly saw a 3x production efficiency increase during rush hours,” says Nora Liu, founder of Sundae Republic (LA-based parlor). “And that boosted cone upsells by 42%.”

Types of Commercial Ice Cream Cone Equipment: Choose Based on Output Flow

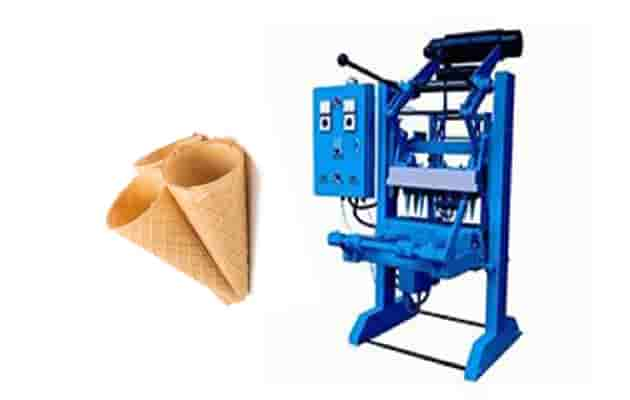

1. Semi-Automatic Waffle Cone Iron (Standard Model)

- Best for shops producing <300 Бутал / өдөр

- Manual batter portioning and cone rolling

- Ойролцоох. $250–$800 investment

2. Dual Plate or Twin-Deck Machines

- Two independent irons with separate thermostats

- Гарц: ~100–180 cones/hour

- Ideal for shops with multi-scooping stations

- Үнэ: $800–$1,500

3. Rotary Automatic Cone Makers

- Автомат зуурмаг хооллох, шуурхай, and rolling

- Учир нь enterprise-grade or factory-level production

- Гарц: 1,000–3,000 cones/hour

- Үнэ: $5,000–$25,000+

Pro Insight:

If your peak-hour sales exceed 15 cones in 10 минут, manual cone rolling becomes a bottleneck. In this case, either shift to twin-deck operation or pre-roll during off-peak prep windows.

Thermal Profiles and Material Selection: Яагаад энэ нь чухал юм

Heating Core Types

- Coil-based heaters offer stable mid-range baking but can have hotspots.

- Induction-based cores provide faster thermal recovery (ideal for back-to-back cones).

Plate Composition

- Цутгамал төмр: Longer preheat but superior heat retention—great for crispy edges.

- Teflon-coated aluminum: Quick heat-up, but shorter lifespan and prone to warping under heavy use.

А 2023 survey from The Frozen Dessert Association showed that:

Shops using cast-iron based waffle makers had a 9% higher cone crispness satisfaction rating in customer reviews than those using aluminum units.

Real-World Workflow: Integrating a Waffle Cone Station

Let’s examine how Lick & Roll Creamery in Austin optimized their line:

Before Optimization

- One single-plate waffle cone maker

- 5-minute prep time per cone

- Frequent plate cooling between uses

→ Result: 7-minute average wait per customer

After Optimization

- Upgraded to a twin-head ALDKitchen machine with digital PID control

- Implemented 2-person workflow: one for batter ladling, one for rolling

- Built a cone cooling rack using food-grade mesh trays

→ Result: 2.5-minute customer turnaround, +28% in average order value via cone upsells

Batching, Pre-Rolling, and Shelf Life: Operational Tactics That Work

You don’t always need to bake on demand. Many successful shops pre-bake and store cones during prep hours.

Storage Tips:

- Cool cones fully on wire racks before storing

- Use airtight, silica-lined food bins to retain crispness

- Shelf life: 24–36 hours for optimal texture

“We do three 60-cone batches at 8 AM, which covers lunch traffic. During high school release at 3 PM, we switch to hot rolling for the aroma effect,” says Javier Corroza, co-owner of Helado Fresco in Miami.

This hybrid approach ensures efficiency without sacrificing customer sensory appeal.

Recipe Development: The Science of a Crunchy Cone

Here’s a base commercial waffle cone batter recipe, plus tweaks for performance.

Basic Ratio (Түүгээр 100 cones):

- Гурил: 1,200гэр

- Элсэн чихэр: 800гэр

- Үсний улаан хоолой: 12 том

- Butter: 500гэр (хэвлэсэн)

- Vanilla: 25гэр

- Давс: 10гэр

- Milk or water: 600–750ml (adjust for viscosity)

Performance Tweaks:

- Add 2% malt powder for deeper flavor and browning

- Хэрэглэх төмсний цардуул (5–7%) for improved snap texture

- Replace some butter with refined coconut oil for higher crispness retention

Үл: Measure batter viscosity using a Bostwick Consistometer to maintain output uniformity between batches.

Avoid These Common Pitfalls in Waffle Cone Production

| Асуудал | Likely Cause | Шийдэл |

|---|---|---|

| Cones too soft after cooling | High moisture in batter | Reduce milk/water by 10%, increase bake time |

| Cones cracking during roll | Not rolled hot enough | Roll within 5 seconds post-lift |

| Конус хавтан дээр наалддаг | Incomplete seasoning or old Teflon | Apply food-grade release agent or replace plate |

Дандаа run QC testing during your first batch daily. An undercooked cone or sticky iron can create a production backlog you can’t afford at 5 PM.

Marketing Insights: Turn Waffle Cone-Making into a Visual Experience

Consumers eat with their eyes—and noses.

Live Cone Baking as a Marketing Tool:

- Position cone maker near the order window

- Use exhaust fans to waft scent toward the entrance

- Highlight “Freshly Baked Daily” on menus

- Offer limited edition cones (сүйт, chocolate swirl, шанц)

Instagram-worthy Tip:

Offer dipped cones (Жишээ нь e., chocolate with crushed almonds) and charge $1.00 extra. This simple upgrade can lift your daily revenue by $50-100 with minimal overhead.

Key Metrics to Monitor ROI on Your Cone Station

| Metric | Benchmark |

|---|---|

| Cone cost per unit | $0.07–$0.11 |

| Cone upcharge over cup | $0.50–$1.00 |

| Average cone sales/day | 80-150 (high season) |

| Payback period on $1,000 машин | 15-30 өдөр |

Once you pass your ROI threshold, cones become a high-margin product—often with 700–1,200% markup.

Top-Rated Commercial Cone Makers (2024 Зөвлөвлөг)

| Brand | Загвар | Төрөл | Output/hr | Үнэ (Гурш) |

|---|---|---|---|---|

| ALDKitchen | Dual Iron | Гарын авлага | 120 | $699 |

| Krampouz | Professional Series | Гарын авлага | 140 | $980 |

| VEVOR | Semi-Auto | Гарын авлага | 100 | $299 |

| TT Italy | RCM Series | Автоматжүүлал | 2,000+ | $9,800 |

If you’re considering scale, contact manufacturers about OEM custom cone sizes эсвэл custom-embossed plates for brand differentiation.

Байгуулах: Own the Cone, Elevate the Brand

In 2025’s competitive dessert market, аг commercial ice cream waffle cone maker is more than just an appliance—it’s a statement. It tells customers you care about quality, шинэлэг байдал, and experience. It gives your brand a point of difference no competitor’s frozen, boxed cone can match.

Whether you’re crafting 80 cones a day or scaling into the thousands, the right machine paired with smart workflow and recipe control can elevate your profits—and your brand story.