Оршил: Жигнэмэг үйлдвэрлэл гаргах

Өндөр чанартай жигнэмэгийн дэлхийн эрэлт нь өсөлтөд тасралтгүй байдаг, Тохиромжтой худалдан авагчийн давуу эрхээр удирддаг, дур булаам, ба боломжийн зууш. Энэ нь тууштай байдлыг хангахад өсч томрох эрэлтийг хангах, эрүүл ахуй, ба үр ашиг, аг Бүрэн автомат жигнэмэг үйлдвэрлэлийн шугам үйлдвэрлэлийн хүнсний үйлдвэрлэлийн алтан стандарт болсон.

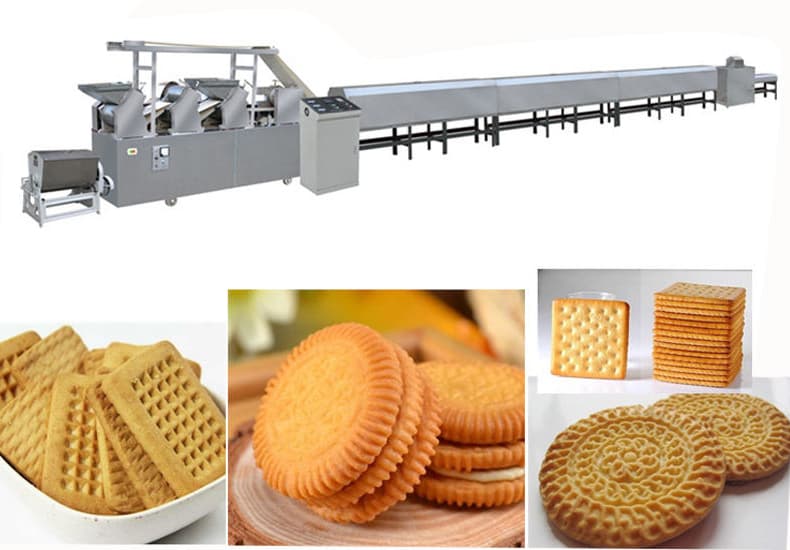

Энэ нийтлэл нь орчин үеийн тоймыг танилцуулж байна Biscuct үйлдвэрлэлийн шугам, оролцсон машин механизмыг нарийвчлан авах, Үйлдвэрлэлийн урсгал, техникийн үзүүлэлт, Автоматжуулалтын онцлог, Дэлхий даяар жигнэмэгийн үйлдвэрүүдэд зориулсан бизнесийн давуу талууд.

1. Бүрэн автомат жигнэмэг үйлдвэрлэлийн шугам гэж юу вэ?

А Бүрэн автомат жигнэмэг үйлдвэрлэлийн шугам нь түүхий найрлагыг боловсруулж боловсруулсан техник хэрэгслийн нэгдсэн систем юм, Автомат үйл ажиллагаагаар жигнэмэг савласан. Энэ нь холимог гэх мэт янз бүрийн үе шатанд гарын авлагын хөдөлмөрийн хэрэгцээг арилгана, гэсэн байна, жигнэх, тайвшуу, ба сав баглаа боодол.

Сонгодог цөцгийн тосны жигнэмэгийг тосоор дүүргэсэн сэндвич жигнэмэг, Энэхүү үйлдвэрлэлийн шугам нь олон тооны бүтээгдэхүүний олон төрлийн бүтээгдэхүүний олон төрлийн бүтээгдэхүүнийг өндөр нарийвчлалтай, хамгийн бага хог хаягдалтай болгодог.

2. Жигнэмэг үйлдвэрлэлийн шугамын гол бүрэлдэхүүн хэсэг

Мэргэжлийн Biscuct үйлдвэрлэлийн шугам дараахь гол тоног төхөөрөмжөөс бүрдэнэ:

2.1 Зуурсан гурилан холигч

- Холимог гурилыг холино, тарган, ус, элсэн чихэр, мөн нэг жигд зуурсан гурил.

- Сонголт: Хэвтээ холигч, Босоо спираль холигч.

2.2 Зуурмаг хооллох конвейер

- Зуурсан гурилыг бүрдүүлэх машин руу шилжүүлнэ.

- Зэвэрдэггүй ган барилгын тусламжтайгаар хурдацтай удирддаг.

2.3 Жигнэмэг үүсгэх машин

- Төршил: Эргэдэг галзуу, дириттер эдлэл, утас таслах, эсвэл экструдер.

- Өөр өөр жигнэмэг хэлбэр, хэв маягийн хувьд өөрчлөн.

2.4 Хонгил жигнэх зуух

- Дөө бичиг: Цахилгаан, байгалийн хий, Дизель, эсвэл хэт улаан туяаны.

- Нарийн хяналтанд температуртай бүсийг жигд жигнэх.

2.5 Тост сэлмэл (Сайн дурын)

- Нарийн болон гялалзсан байдал, гялалзсан байдал, амтат, амтыг сайжруулах зорилгоор хэрэглэнэ.

2.6 Жигнэмэг хөргөх конвейер

- Савласан жигнэмэгийн температурыг баглаа боодолоос өмнө бууруулдаг.

- Бүтээгдэхүүний бат бөх байдлыг баталгаажуулж, конденсацаас сэргийлдэг.

2.7 Шатах шугам

- Төршил: Хэвтээ урсгалын боодол, Босоо хэлбэртэй хэлбэртэй (Урсгал ороо).

- Ан тэмдэгт: ӨНГӨ ОРУУЛАЛТ, азот урсах, Шошгоны програм.

3. Техникийн үзүүлэлт

| Зөнийн тавь чанар | Лал дохолт |

|---|---|

| Борл дуусах | 100 кг / цаг хүртэл 2000 кг/цаг |

| Biscuckit төрөл дэмжигдсэн | Хатуу жигнэмэг, зөөлөн жигнэмэг, хачиртай талх, шилжт |

| Зуухны урт | 20м-60м (тохируулах боломжтой) |

| Дөө бичиг | Цахилгаан / Байгалийн хий / Дизель / Lepg |

| Цалин зүй | 50 KW - 200 кВт (Тохиргооны дагуу өөр өөр байдаг) |

| Шарах цонх | 380V / 50 цаг 3 Үе / үелэл (тохируулах боломжтой) |

| Удирдлагын систем | Импорт + Томми (Дэлгэцийн самбар) |

| Материал | Хоол хүнс-ангийн Sus304 зэвэрдэггүй ган |

| Хоолийн хурд | 25-40 хүртэлх хөгц / мин (төрлөөс хамаарна) |

| Мөрний хурдны хурд | 20-120 багц / мин |

4. Үйлдвэрлэлийн үйл явцын урсгал

Шат 1: Зуурмагийн бэлтгэл

Орцыг жинлэж, автомат холигч дээр холилдов.

Шат 2: Зуурмаг Зууралт дор

Холимог зуурсан гурилыг хүн төрөлхтний холбоо барих системд шилжүүлдэг.

Шат 3: Жигнэмэг үүсэх

Жигнэмэг нь эргэдэг таслагч эсвэл гаднах хэсгийг ашиглан хэлбэртэй байдаг, Зуурсан гурилын хуудас эсвэл бие даасан жигнэмэг үүсгэдэг.

Шат 4: Туун

Хэлбэртэй жигнэмэг нь олон температуртай хонгилын зуухаар дамждаг.

Шат 5: Тайвшуу

Шатаасан жигнэмэг нь жигд жигнэмэг нь хэлбэр, бүтэцээ хадгалахын тулд жигд жигнэмэгээр хөргөнө.

Шат 6: Сав баглаа боодол

Жигнэмэг нь нийцэж байна, Тай, цүнхэнд баглаа боодол, таваг, эсвэл хайрцаг автоматаар.

5. Үйлдвэрлэсэн жигнэмэгийн төрөл

А Biscuct үйлдвэрлэлийн шугам жигнэмэгийн янз бүрийн хэвшмэл хэв маягийг үйлдвэрлэх боломжтой:

| Жигнэмэгийн төрөл | Тодорхойлолт |

|---|---|

| Хатуу жигнэмэг | Бага чихэртэй / өөх тос, Үйрмэг бүтэцтэй (Жишээ нь e., Хэлэлцэх, Хужир) |

| Зөөлөн жигнэмэг | Өндөр элсэн чихэр / өөх тос, зөөлөн бүтэцтэй (Жишээ нь e., Богинохон) |

| Цөцгийтэй сэндвич жигнэмэг | Цөцгий дүүргэлт бүхий хоёр жигнэмэг |

| Шилжт | Зузаан, зажлах бүтэцтэй (Ихэнхдээ утсыг таслав) |

| BAWAGE BEICKESS | Тос дүүргэх нимгэн давхарга |

6. Автомажуулалт & Ухаалаг шинж чанарууд

- Plc хяналтын самбар - Параметрүүдийг бодит цагийн хяналт, тохируулга хийх.

- HMI-ийн дэлгэцийн HMI - Хэрэглэсэн хэрэглэгчдийн ээлтэй интерфейс.

- Температур мэдрэгч - Олон бүсийн зуухны температурын журам.

- Servo мотор хөтөч - нарийвчлалтай жигнэмэг үүсэх, тэгшлэх.

- Алсын удирдлага (Сайн дурын) - IOT CLOSE холболтоор дамжуулан дэмжлэг үзүүлэх.

7. Бүрэн автомат жигнэмэг үйлдвэрлэлийн шугамын давуу талууд

Ий 1. Нэмэгдэх үр ашиг

Үргэлжилсэн, Хамгийн бага цаг хугацааны өндөр хурдтай үйлдвэрлэл.

Ий 2. Тууштай бүтээгдэхүүний чанар

Үнэн зөв найрлагатай тунг, гэсэн байна, жигд жигнэмэг бүрийг жигд болгодог.

Ий 3. Хөдөлмөрийн зардлыг бууруулах

Бүрэн автоматжуулсан үйл ажиллагаа нь гарын авлагын хөдөлмөрийн хэрэгцээг эрс бууруулдаг.

Ий 4. Эрүүл ахуй, аюулгүй байдал

Хүнсний зүүний зэвэрдэггүй ган тоног төхөөрөмжтэй хаалттай боловсруулах нь HACCP болон GMP стандартад нийцдэг.

Ий 5. Эрчим хүч оновчтой болгох

Орчин үеийн зуух, дамжуулагч нь эрчим хүчний үр ашгийг ашиглах зориулалттай.

8. Үйлдвэрийн байршил

Жигнэмэг үйлдвэрт суурилсан байх ёстой:

- Борл дуусах

- Түүхий эд, бэлэн бараа хадгалах санс

- Агааржуулалт ба дулааны дулаалгын бүс

- Зуурсан гурилыг тусдаа бүс, жигнэх, тайвшуу, ба сав баглаа боодол

- Эрчим хүч, усны хангамжийн бэлэн байдал

Ердийн зохион байгуулалт нь хооронд нь байж болно 25 метр давтаж 100 метр урт Гаралт ба жигнэмэгийн төрлөөс хамаарна.

9. Хэрэгжүүлэх Сандал: 1000 KG / H жигнэмэг үйлдвэрлэлийн шугам

Үйлчлүүлэгч: Зүүн Өмнөд Азийн зууш үйлдвэрлэгч

Тохируулах онцлох үйл явдлууд:

- 60-метрийн хийн зуух

- Хэл хэлбэрийн өөрчлөлтөд зориулсан хос эргэдэг таслагч

- Азот дүүргэсэн хэвтээ сав баглаа боодол

- 24/7 мэс засал, гурван ээлж

Үр дүн:

- Үйлдвэрлэл 4 × нэмэгдсэн

- Хог хаягдлыг бууруулсан 35%

- ROI нь хүрсэн 14 сар

10. Нийтлэг худалдан авагчийн асуултууд (Rfq хэсэг)

Q1: Хамгийн бага хүчин чадал нь юу вэ?

А: Манай хамгийн жижиг жигнэмэг үйлдвэрлэлийн шугам эхэлнэ 100 кг/цаг, Жижиг болон дунд зэргийн үйлдвэрүүдэд хамгийн тохиромжтой.

Q2: Үйлдвэрлэлийн шугам нь өөр өөр жигнэмэг хэлбэрийг зохицуулж болно?

А: Мон, Мөөгөнцөр нь янз бүрийн хэлбэр, хэв маягийг дэмжих зорилгоор хурдан сольж болно.

Q3: Операторын сургалт өгсөн?

А: Мон, Бид танай ажилтнуудад сайт эсвэл алсын сургалт явуулдаг.

Q4: Шугам нь одоо байгаа ургамалд нэгтгэж болно?

А: Үнэхээр. Бид одоо байгаа дэд бүтцийг тааруулахын тулд зохион байгуулалтыг тохируулж өгдөг.

Q5: Хүргэлтийн хугацаа хэр удаан?

А: Стандарт хүргэлт нь тохиргооноос хамаарч 35-60 хоног юм.

11. Засвар үйлчилгээ, дэмжлэг

- Засвар үйлчилгээний хуваарь

Холхивч дээр тогтмол шалгалт хийх, бүсхан, сахиусан хүүхдүүд, болон мэдрэгч. - Сэлбэг эд ангиудын хүртээмж

Шүүмжлэлтэй бүрэлдэхүүн хэсгүүдэд зориулсан хурдан хүргэх. - Алсын оношлогоо

Аж үйлдвэрийн чиглэлээр дамжуулан идэвхжүүлсэн ба PLC оношлогоо.

12. Үнэ & Хэмжөнг өгөөх

| Хүчин чадал | Ойролцоо үнэ (Гурш) |

|---|---|

| 100-200 кг / цаг | $35,000 Өмнөөс $60,000 |

| 300-500 кг / цаг | $70,000 Өмнөөс $120,000 |

| 800-1000 кг / цаг | $150,000 Өмнөөс $220,000 |

| 1500 кг / h + | $250,000 ба түүнээс дээш |

Roi үе: Ихэвчлэн 12 руу 24 Хэмжээ, зах зээлийн нөхцөл байдлаас хамааран сарууд.

13. Зах зээлийн чиг хандлага & Ирээдүйн төлөв

- Эрэлт хэрэгцээ эрүүл мэнд жигнэмэг (бага зэрэг элсэн, цавуулаггүй).

- Хөрөнгө оруулалт ургадаг ухаалаг үйлдвэр ба Аж үйлдвэр 4.0.

- Африк дахь экспортын боломжийг нэмэгдүүлэх, Ойрхи Дорнод, ба Латин Америк.

14. Байгуулах: Бинци үйлдвэрээ өөртөө итгэлтэйгээр барь

Бүрэн автомат Biscuct үйлдвэрлэлийн шугам Хоол хүнс үйлдвэрлэгчдэд өндөр чанартай бүтээгдэхүүн үйлдвэрлэхэд өндөр чанартай бүтээгдэхүүн хүргэх, эрүүл ахуй, болон уян хатан байдал. Та жигнэмэг тариалж эхэлж эсвэл байгууламжаа сайжруулж байгаа эсэх, Орчин үеийн жигнэмэг үйлдвэрлэлийн технологид хөрөнгө оруулалт хийх нь урт хугацааны ашигт малтмалын эрдэнэ шишийн үйсэн юм.

Дараагийн алхамыг авахад бэлэн байна? Тохируулсан саналд бидэнтэй холбоо бариарай, зохион байгуулалтын загвар, ба үнийн сурталчилгаа.