Гоймонгийн гоймонгийн эрэлт улмаас босов, тухайлах ялгац гишүүн Автомат Macaroni үйлдвэрлэгч машин үйлдвэрлэлийн үр дүнг үр дүнтэй болгохын тулд хүнсний процессоруудын үдээс болж. Жижиг гар урчууд үйлдвэрлэгчдээс үйлдвэрлэлийн паста үйлдвэрлэгчид, Эдгээр машинууд нь макарони хэрхэн илүү хурдан хийгддэг болохыг өөрчилдөг, цэвэрлэгч, өмнөхөөсөө илүү.

Эдгээр орчин үеийн машинуудын талаар мэдэхийн тулд бид бүх зүйлийг судалдаг, зэрэг урт сүүл, ижил утгатай үг хэллэгийг ашиглан Macaroni хэлбэрийн тоног төхөөрөмж, паста үүсэх машин, ба Автомат паста үйлдвэрлэлийн нэгж Тойм тойм өгөх.

1. Арилжааны макарони үйлдвэрлэгч: Хоол боловсруулах зориулалттай тоглоом

The арилжааны макарони үйлдвэрлэгч нь Macaroni үйлдвэрлэлийн үйл явцыг бүхэлд нь автоматжуулах зориулалттай тусгай төхөөрөмж юм. Энэ нь орцыг холино, Зуурмагийг нарийн хэлбэрт оруулав, мөн хатаах пастагаа хатаахаар бэлддэг.

1.1 Хэрхэн ажилладаг

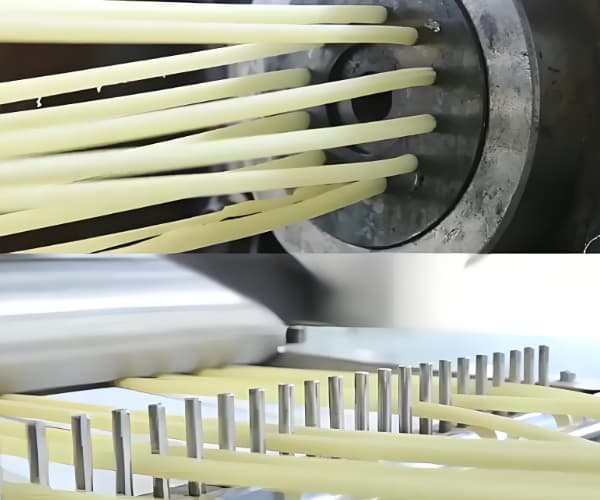

Машин нь Durum Whange Semolina шиг түүхий эдийг донум улаан буудайн семолина шиг хослуулдаг, ус, нэмэлт нэмэлт, Тэднийг зуурсан гурил болгон хутгана, тодорхой макарони хэлбэрийг бий болгохын тулд үхэлд хүргэдэг. Зуурмаг нь хэлбэртэй байдаг, тайрах, хатаах нэгж рүү явуулсан, сав баглаа боодол бэлэн байна.

1.2 Үүнийг хэн ашигладаг вэ?

- Үйлдвэрлэлийн нэвтрэлтийн үйлдвэрүүд

- Дунд зэргийн хэмжээтэй хүнсний үйлдвэрлэгчид

- Төв гал тогооны өрөө, үүлний гал тогоо

- Экспортод чиглэсэн хүнсний бизнесүүд

2. Паста үүсэх машин: Макарони үйлдвэрлэлийн гол бүрэлдэхүүн хэсэг

The паста үүсэх машин нь аливаа автомат Макарони үйлдвэрлэгчийн төв юм. Түүний үндсэн функц нь Confory-Inision-Ingered DieS-ийг ашиглан паста зуурсан гурил үүсгэх явдал юм.

2.1 Ихэр шураг эсвэл дан шураг?

Орчин үеийн хэлбэржүүлэх машинууд нь а ганц биелэг эсвэл ихэр шураг Систем:

- Ганц биелэг: Дунд зэргийн бага гаралтын хувьд тохиромжтой

- Ихэр шураг: Илүү сайн холих, тууштай байх өндөр түвшний тасралтгүй үйлдвэрлэлд тохиромжтой

2.2 Хуваалцаж болох үхлийн загварууд

ХОЁРДУГААР МӨНГӨ ОРУУЛАЛТЫГ УРЬЖ БАЙНА УУ, шулуун зүсэлт, аль нь, борлах, тэр ч байтугай хөндий спираль.

3. Аж үйлдвэрийн гоймонгийн extra offuder

The аж үйлдвэрийн хэргээр бүтэгчлэгч нь чанарын болон гаралтыг хамгийн их хэмжээгээр нэмэгдүүлдэг онцлог шинж чанаруудтай том хэмжээний паста үйлдвэрлэл.

3.1 Гол давуу талууд

- Хүнд хүчин чадал: 200-500 кг / цаг үйлдвэрлэж болно

- Тасралтгүй ажиллагаа: Бий болгож байна 24/7 Үйлдвэрлэлийн мөчлөг

- ТУВИЙН: Жигд хэлбэрийг баталгаажуулдаг, даавуу, болон нягтлан ногоо

- Хүүр Тимийн барилгын: Хүнсний зэрэглэлийн зэвэрдэггүй ган, хаалттай гогцоо загвар

3.2 Материалыг боловсруулсан

- Durum Hheehe гурил

- Бүхэл бүтэн улаан буудайн гурил

- Цавуулаггүй гурилын холимог

- Нэмэгдсэн шим тэжээл бүхий гурилыг баяжуулсан

4. Macaroni хэлбэрийн тоног төхөөрөмж: Нарийвчлалтай, уян хатан байдал

Macaroni хэлбэрийн тоног төхөөрөмж Пастала бүрийг тодорхой хэмжээнд нийцэж байгаа эсэхийг шалгадаг, хэлбэр, ба тууштай байдал.

4.1 Хувьсах хэлбэрийн сонголтууд

Нэг машинтай, Та хэлж чадна:

- Тохой макарони

- Хясраал

- Ригатони

- Борлах

- Захиалгат гар артисанал хэлбэр (хүсэлтээр)

4.2 ХУДАЛДАН АВАХ ТЕХНОЛОГЕЛ

Нарийвчилсан хэлбэржүүлэх механизм ба өндөр нарийвчлалтай тасалдал, өндөр хурдны үрэлгэн, анхны хатаах үед бүрэн бүтэн байдлыг бий болгодог.

5. Автомат паста үйлдвэрлэлийн нэгж: Цахилгааны шийдэл бүрэн

А бүрэн автоматжуулсан паста үйлдвэрлэлийн нэгж Үйлдвэрлэлийн үйл явцын үе шат бүрийг нэгтгэдэг, паста бизнес эрхлэхийн тулд цогц шийдлийг санал болгож байна.

5.1 Үйл явц

- Хоолек систем: Автомат гурил, усны тун

- Халвар Хих: Зуурсан гурил зуурах зуурмаг

- Үүсэх хэрэгсэл: Үхэх замаар гоймон үүсгэдэг

- Хайм систем: Rotary таслагч хэлбэрийн хэлбэр

- Урьдчилан хатаагч: Гадаргуугийн чийгийг арилгадаг

- Хатаах танхим: Бүрэн автоматжуулсан олон шаттай хатаагч

- Хөргөх хэсэг: Сав баглаа боодлын бүтээгдэхүүнийг тогтворжуулах

5.2 Бүрэн автоматжуулалтын ашиг тус

- Хөдөлмөрийн бууралт

- Алдааг багасгах

- Сайжруулсан эрүүл ахуй

- Бизнес эрхлэхэд зориулсан хурдан ROI

6. Стандарт автомат Macaroni үйлдвэрлэгчийн техникийн үзүүлэлтүүд

Доорх нь дунд хүчин чадлын дээжийн тодорхойлолт юм Автомат Macaroni үйлдвэрлэгч машин:

| Зөнийн тавь чанар | Лал дохолт |

|---|---|

| Борл дуусах | 120-250 кг / цаг |

| Цөсний нөөц | 380В / 50Нз / 3 Үе / үелэл |

| Нийт суулгасан хүч | 68 кВт |

| Машины хэмжээ (L × w × цаг) | 30000 mm × 1800 mm × 2200 мм |

| Олешгүй бичих | Ихэр шураг шураг |

| Ү үхтєд | Teflon-бүрсэн хүрэл / зэвэрдэггүй ган |

| Удирдлагын систем | Siemens Touchcreen HMI-тэй Siemens Plc |

| Биеийн мөр | SUS304 зэвэрдэггүй ган |

| Паста хэлбэрийг дэмждэг | Эрерморони, тохой, борлах, fusilli, гэх мэт. |

| Хатаагч төрөл | Агаарын хяналттай тасралтгүй бүс хатаагч |

Эдгээр техникийн үзүүлэлтүүд нь үйлчлүүлэгчийн үйлдвэрлэлийн зорилго, байршлын зайнаас хамаарч тохируулж болно.

7. Макарони үүсэх систем

The макарон хэлбэржүүлэх систем Өндөр хурдтай эргэлттэй таслагч, паста нь ижил хэмжигдэхүүн, бүтцийн бүрэн бүтэн байдлыг хангах үүднээс баталгаажуулахын тулд өндөр хурдны тогтвортой байдлыг багтаадаг.

7.1 Агаар хөргөх эсвэл усны хүрэм систем

Наалдамхай байдлаас урьдчилан сэргийлэх, хэлбэржүүлэх явцад гоймонгийн бүтэц хадгалах, Агаар эсвэл усан хөргөлтийн хүрэм нь үржил шимтэй торхны эргэн тойронд ашиглагддаг.

7.2 Тохируулж болох зузаан

Операторууд нь үйлчлүүлэгчдийн давуу талаас хамааран зузаан эсвэл нимгэн, нимгэн эсвэл нимгэн макароныг хялбаршуулахын тулд зуурмагийн шахалтын түвшинг амархан туулаад болно.

8. Арилжааны паспортын үйлдвэрлэлийн машин засвар үйлчилгээ

Байлгах Арилжааны паста үйлдвэрлэлийн машин нь тууштай чанар, урт машины амьдралын хувьд зайлшгүй шаардлагатай.

8.1 Өдөр тутмын засвар үйлчилгээний зөвлөмж

- Блоколтоос урьдчилан сэргийлэхийн тулд цэвэр үхэл, торх

- Таслагчийг шалгана уу

- Бохирдлоос зайлсхийхийн тулд гадаад гадаргууг арчина

8.2 Сарын засвар үйлчилгээ

- Мотор бүс, тосолгооны цэгүүдийг шалгана уу

- Туршилтын цахилгаан холболт ба мэдрэгч

- Backup Plc програм хангамж

9. Өндөр хүчин чадлын паста боловсруулах шугам: Том хэмжээний байгууламжийн хувьд

The өндөр хүчин чадлын паста боловсруулах шугам нь олон үндэстэн, найдвартай экспортлогдод тохиромжтой.

9.1 Борл дуусах

Top-Tier Machines нь дээшлэх боломжтой 1000 kg / цаг ба түүнээс дээш, тэдгээрийг тохируулах:

- Супермаркет хүрээ

- ХӨДӨЛМӨРИЙН ХУГАЦАА

- Компаниуд эксжсон компаниуд

9.2 Сав баглаа боодлын системтэй нэгтгэх

Эдгээр машинууд нь хялбархан холбогддог:

- Дөрвөлөгчд суурилсан эрэмбэлэх системүүд

- Жинлэх машин

- Босоо хэлбэртэй хэлбэртэй (Урсгал ороо) сав баглаа боодол

- Шошго, боксын машинууд

10. Smes-д зориулсан компактын пастер машин

The Компакт паста машин нь хязгаарлагдмал орон зай бүхий жижиг дунд бизнес эрхлэхэд зориулагдсан боловч өндөр чанартай хэрэгцээтэй байдаг.

10.1 Гол онцлогууд

- Space-FORMING хөлийн ул мөр

- Ажиллуулахад хялбар

- Хурдан хөгширсөн

- Төсвийн ээлтэй автоматжуулалт

10.2 Тохиромжтой:

- Орон нутгийн паста брэндүүд

- Органик эсвэл цавуулаггүй паста стартапууд

- Ресторан, комиссарууд

11. Macaroni үйлдвэрлэлийн тоног төхөөрөмж дахь эрчим хүчний үр ашиг

Тогтвортой байдал одоо хамгийн чухал ач холбогдолтой юм. Орчин үеийн Macaroni үйлдвэрлэлийн тоног төхөөрөмж Хэд хэдэн эрчим хүч хэмнэлттэй шинэлэг зүйл орно:

- Бага эрчим хүчний үрэлгэн систем

- Хатаагч дахь дулааны сэргээх модулиуд

- Сул зогсолтын үеэр ухаалаг хүч хэмнэх горимууд

- Дулааны алдагдлыг бууруулахын тулд хатаах хааны тасалбарууд

12. Гоймон дахь аюулгүй байдал, эрүүл ахуйн эрүүл ахуй

Хүнсний аюулгүй байдал нь аливаа хүнсний боловсруулалтын тоног төхөөрөмжид байдаг.

12.1 Эрүүл ахуйн онцлог шинж чанарууд

- Бүх хүнсний холбоо барих хэсгүүдийг арилгах, ариутгахад хялбар байдаг

- Зэвэрдэггүй ган гадаргуу нь бактерийн өсөлтөөс урьдчилан сэргийлдэг

- Битүүмжилсэн электроникууд чийгийн эвдрэлээс зайлсхийдэг

12.2 Аюулгүй ажиллагааны арга хэмжээ

- Яаралтай зогсоох товчлуурууд

- Хэт халалт эсвэл хэт ачаалал дээр автоматаар унтрах

- Хандалтын хаалган дээр аюулгүй байдал орно

13. Баруун автомат гоймон хийх тоног төхөөрөмжийг сонгох

Хөрөнгө оруулалт хийх үед Автомат гоймон хийх тоног төхөөрөмж, анхаарч үзэх:

- Хүссэн гаралтын хүчин чадал

- Гоймон хэлбэрийн төрөл бүрийн

- Машины өргөжүүлэх

- Борлуулалтын дараах үйлчилгээ, сэлбэг хэрэгслийн хүрээнд

- Гэрчилгээний (Члэл авчээ, Исаа, гэх мэт.)

14. Паста үйлдвэрлэлийн машин дахь ирээдүйн чиг хандлага

14.1 AI болон ухаалаг хяналт

AI-дүүнд суурилсан паста машинууд удахгүй найрлагын өөрчлөлтүүдэд дасан зохицох болно, Зуурсан гурилын бүтэц нь өөрчлөгдөж, ялаа дээр нүүлгэн шилжүүлэх тохиргоог оновчтой болгох.

14.2 Тогтвортой үйлдвэрлэлийн шугамууд

- Нарны хүчдэлтэй гоймон

- Дахин боловсруулж болох үхлийн материалууд

- Нүүрстөрөгч-Төвийг сахисан паста үйлдвэрүүд

Байгуулах

The Автомат Macaroni үйлдвэрлэгч машин нь паста үйлдвэрлэлд оролцсон аливаа бизнесийн өөрчлөлт юм. Жижигхэн паста эхлүүлэх эсвэл томоохон хэмжээний арилжааны байгууламжийг удирдах эсэх, Зөв машин нь таны бүтээмжийг эрс сайжруулж чадна, төвөг, чанарын.

Автоматжуулалтын дэвшилтэд баярлалаа, хайхрамжгүй технологи, болон эрүүл ахуйн стандарт, амттай хий, төгс хэлбэртэй макарони хэзээ ч илүү хялбар, үр дүнтэй байдаггүй. Хүнсний үйлдвэрлэл нь даяаржаар үргэлжилж байна, найдвартай, масштабтай паста машин байх нь зөвхөн сонголт биш юм.