Introduction: The Demand for Garlic Processing Equipment

Garlic is a staple in kitchens and food industries worldwide. From sauces to marinades, its bold flavor is irreplaceable. However, processing garlic—especially peeling—is time-consuming and labor-intensive. That’s where garlic peeling machine price come into play.

Whether you’re a restaurant owner, food processor, or garlic distributor, understanding the garlic peeling machine price and its value can help you make a smart investment.

What Is a Garlic Peeling Machine?

A garlic peeling machine is an industrial or commercial device designed to remove the skin from garlic cloves quickly and efficiently. These machines eliminate the need for manual labor, improve hygiene, and increase productivity.

Long-Tail Keywords & Synonyms:

- Automatic garlic peeler price

- Garlic skin removing machine cost

- Commercial garlic peeling machine

- Garlic clove peeler machine

Types of Garlic Peeling Machines

To understand the variation in garlic peeling machine price, it’s essential to know the different machine types available.

1. Dry Type Garlic Peeling Machine

This type uses compressed air to peel garlic without using water.

Features:

- No water consumption

- High peeling efficiency (90–95%)

- Minimal damage to garlic cloves

Ideal for:

- Medium to large-scale garlic processors

2. Wet Type Garlic Peeling Machine

This machine uses water to soak and peel the garlic.

Features:

- Softer on garlic skin

- Requires water management

- Suitable for softer garlic varieties

Ideal for:

- Small-scale food processors or restaurants

3. Garlic Peeling Line (Fully Automatic)

A full garlic processing line includes:

- Garlic separating machine

- Garlic peeling machine

- Garlic washing & drying units

- Conveyor and packaging systems

Ideal for:

- Large-scale garlic processing factories

Factors Affecting Garlic Peeling Machine Price

Understanding these factors will help you choose the right machine for your budget and processing needs.

1. Capacity (kg/h)

Higher capacity machines generally have a higher price.

| Capacity | Suitable for | Price Range (USD) |

|---|---|---|

| 20–50 kg/h | Small kitchens/restaurants | $500–$1,200 |

| 100–200 kg/h | Small food factories | $1,500–$3,500 |

| 300–500 kg/h | Industrial use | $4,000–$8,000 |

| 800+ kg/h | Large garlic factories | $10,000–$20,000 |

2. Material Quality

Machines made from high-quality stainless steel are more durable and food-safe but also more expensive.

3. Automation Level

A fully automated garlic peeler will have a higher price due to its advanced control systems and integration with other processing units.

4. Country of Manufacture

Chinese garlic peeling machines are often more cost-effective compared to European or American brands with similar specs.

Garlic Peeling Machine Price Overview by Type

Dry Type Garlic Peeling Machine Price

This type is the most popular for commercial use.

Example Models:

| Model | Capacity (kg/h) | Power (kW) | Air Pressure (MPa) | Price (USD) |

|---|---|---|---|---|

| GPM-100 | 100 | 0.2 | 0.6–0.8 | $1,250 |

| GPM-200 | 200 | 0.3 | 0.6–0.8 | $2,400 |

| GPM-500 | 500 | 0.6 | 0.8–1.0 | $5,200 |

Wet Type Garlic Peeling Machine Price

Wet types are lower in cost but require more maintenance.

| Model | Capacity (kg/h) | Power (kW) | Water Use | Price (USD) |

|---|---|---|---|---|

| WPM-30 | 30 | 0.1 | Moderate | $520 |

| WPM-50 | 50 | 0.15 | Moderate | $890 |

Full Garlic Peeling Line Price

For those looking for complete automation:

| Line Capacity | Components | Price Range (USD) |

|---|---|---|

| 500 kg/h | Separator + Peeler | $6,000–$10,000 |

| 1000 kg/h | Separator + Peeler + Conveyor | $15,000–$20,000 |

How to Choose the Right Garlic Peeling Machine

1. Identify Your Production Volume

A small restaurant will not require the same machine as a garlic exporter.

2. Evaluate Your Budget

While the lowest garlic peeling machine price may be tempting, consider long-term costs like maintenance, repairs, and energy.

3. Check After-Sales Support

Reputable suppliers offer installation guidance, spare parts, and lifetime technical support.

4. Verify Certifications

Look for machines with CE, ISO, or FDA certifications for food-grade safety and quality assurance.

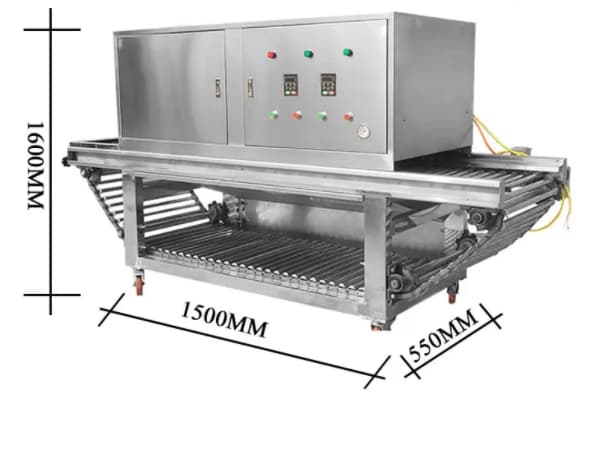

Technical Specifications Sample: Garlic Peeling Machine

| Specification | Value |

|---|---|

| Model | GPM-200 |

| Capacity | 200 kg/h |

| Power | 0.3 kW |

| Air Compressor Req. | 0.6–0.8 MPa |

| Material | SUS304 Stainless Steel |

| Dimensions | 600×800×1100 mm |

| Weight | 120 kg |

Benefits of Investing in a Garlic Peeling Machine

Increased Productivity

Peeling 100 kg of garlic manually may take 4 workers 5 hours. With a machine, it’s done in under 30 minutes.

Labor Cost Savings

Automating garlic peeling reduces dependency on labor and increases overall profit margins.

Improved Hygiene

Minimized hand contact means higher food safety standards.

Consistency

Machines offer uniform peeling, which is important for commercial packaging.

Common Questions About Garlic Peeling Machine Price (RFQ)

Q1: What is the average garlic peeling machine price in 2025?

A: Prices range from $500 for small wet-type machines to over $20,000 for large automated garlic processing lines.

Q2: Do garlic peeling machines require air compressors?

A: Dry-type machines require an external air compressor, which may cost an additional $300–$1,000.

Q3: Are there machines that can both separate and peel garlic?

A: Yes, some integrated garlic processing machines can handle both separation and peeling, saving space and labor.

Q4: What is the warranty period?

A: Most machines come with a 1-year warranty, but some suppliers offer 2–3 years or lifetime support for parts.

Q5: Is it possible to customize the machine?

A: Yes, reputable manufacturers offer customizations for voltage, capacity, material type, and automation level.

Top Global Suppliers of Garlic Peeling Machines

1. DT Food Machine Co., Ltd. (Top Supplier)

Known for their durable dry-type garlic peelers with a competitive price range and international support.

Website: [dtfoodmachine.com]

Price Range: $1,000–$15,000

Support: Multilingual manuals, remote setup, spare parts shipping

2. Zhengzhou Taizy Machinery Co., Ltd.

Offers budget-friendly machines with solid support for African and Southeast Asian markets.

3. Gelgoog Machinery

Premium-grade machines with CE certifications and full garlic processing lines.

Market Trends and Future Outlook

The garlic processing equipment industry is expected to grow due to rising global garlic consumption, particularly in processed food sectors. The demand for cost-efficient machines with automated features will continue to increase.

Key trends include:

- Eco-friendly garlic peeling systems (reduced energy & water)

- Integration with AI-based sorting and packing machines

- Growth in the export of peeled garlic from China, India, and Mexico

Maintenance and Operation Tips

- Clean daily to avoid garlic residue buildup

- Check air compressor regularly for pressure consistency

- Lubricate parts monthly if required

- Replace blades or seals annually depending on use

Conclusion: Is a Garlic Peeling Machine Worth the Price?

Absolutely. Whether you operate a restaurant, garlic farm, or food processing company, the value provided by a garlic peeler outweighs the initial investment.

Understanding the garlic peeling machine price, its components, and features will help you choose the right machine tailored to your business scale. Don’t just look for the cheapest option—consider quality, support, and long-term performance.