Garlic is an essential ingredient in cuisines around the world, but peeling it manually can be time-consuming and labor-intensive—especially in large-scale kitchens or food processing facilities. That’s where a garlic peeling machine becomes invaluable. These machines streamline the peeling process, ensuring efficiency, hygiene, and speed.

This guide covers everything you need to know about garlic peeling machines, including types, technical specifications, how to use them, and tips for choosing the right one.

What Is a Garlic Peeling Machine?

A garlic peeling machine is a piece of equipment designed to remove the outer skin or shell of garlic cloves without damaging the inner flesh. It is commonly used in restaurants, food factories, spice processing units, and commercial kitchens.

Garlic peeling machines operate using different mechanisms, including dry air peeling, roller peeling, or silicone rubbing peeling. Most modern machines prioritize efficiency, hygiene, and automation.

Benefits of Using a Garlic Peeling Machine

- Labor Saving: No need for manual peeling.

- Time Efficiency: Peel hundreds of kilograms in an hour.

- Clean Peeling: No water needed (dry type), reducing mess.

- No Damage to Cloves: Maintains garlic integrity.

- Hygienic: Stainless steel build ensures food safety.

Types of Garlic Peeling Machines

1. Dry Type Garlic Peeling Machines

Uses compressed air to separate the skin from the cloves. It’s popular in industrial setups due to its speed and cleanliness.

2. Silicone Roller Garlic Peeler

Often found in smaller, semi-automatic machines, this type uses friction through rotating silicone rollers.

3. Garlic Peeling Machine with Garlic Separator

A complete garlic processing line includes a garlic bulb breaker, peeler, and sometimes even a slicer or dryer.

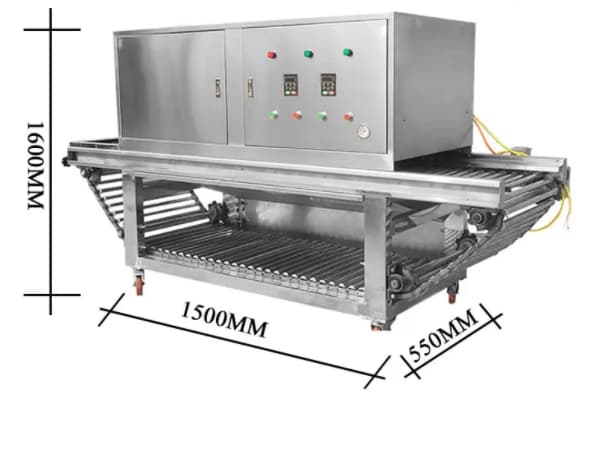

Garlic Peeling Machine Technical Specifications

Below is a sample set of specifications from a standard dry air garlic peeling machine:

| Specification | Description |

|---|---|

| Model | GP-150 |

| Voltage | 220V / 380V |

| Power Consumption | 0.2 – 2.2 kW |

| Air Compressor Needed | Yes (e.g., 1.5kW – 7.5kW) |

| Production Capacity | 150 kg/h – 600 kg/h |

| Peeling Rate | ≥95% |

| Damage Rate | ≤5% |

| Material | Food-grade Stainless Steel (304) |

| Weight | 70 – 120 kg |

| Dimensions | 650×950×1300 mm (varies by model) |

| Noise Level | Low (Air compressor dependent) |

💡 Note: Always check the compatibility between the peeling machine and the air compressor.

How Does a Garlic Peeling Machine Work?

Step-by-Step Process:

- Garlic Separation

If using whole garlic bulbs, first break them into cloves using a garlic clove separating machine. - Air Drying (Optional)

If garlic is moist, an air dryer may be used for optimal peeling. - Feeding Cloves into Peeler

Cloves are placed into the garlic peeling machine’s hopper. - Peeling via Compressed Air

High-pressure air removes the skin from cloves through turbulence and air friction. - Collection and Discharge

Peeled cloves exit from a discharge outlet, while skins are collected separately. - Final Inspection and Packaging

Peeled garlic is ready for processing or packaging.

Long-tail Keywords Related to Garlic Peeling Machine

Commercial Garlic Peeling Machine

Ideal for restaurants, catering services, and medium-sized businesses. Capacities range from 20–50 kg/h. Compact and affordable, they offer basic automation.

Industrial Garlic Peeling Machine

Designed for factories, these machines handle 100–600+ kg/h. Suitable for export-oriented food processing units, spice manufacturers, and seasoning plants.

Automatic Garlic Peeling Machine

Fully automated machines can be integrated with separators, conveyors, and packing machines, minimizing human contact and maximizing productivity.

Small Garlic Peeling Machine for Home Use

Mini versions available for households or small kitchens. Though not suitable for commercial use, they offer convenience for daily cooking.

How to Use a Garlic Peeling Machine Safely

Installation

- Place on a flat, stable surface.

- Connect to a clean air compressor (for dry type machines).

- Ensure proper voltage connection.

Operating Instructions

- Turn on air compressor and wait for pressure to build up (usually 6–8 bar).

- Load garlic cloves into the hopper.

- Activate the start button or foot pedal.

- Garlic peels are blown off and separated.

- Collect the clean, peeled cloves from the output tray.

Maintenance Tips

- Clean after every use to prevent garlic residue buildup.

- Lubricate moving parts regularly.

- Replace silicone rings or nozzles if worn.

- Drain air compressor tank frequently to avoid moisture issues.

Garlic Peeling Machine Price Range

Depending on capacity, material, and automation:

| Type | Capacity | Estimated Price (USD) |

|---|---|---|

| Home Use Garlic Peeler | ~1–5 kg/h | $100 – $300 |

| Small Commercial Machine | 20–50 kg/h | $600 – $1,500 |

| Medium Industrial Peeler | 100–200 kg/h | $2,000 – $5,000 |

| Large-Scale Garlic Peeling Line | 300–1000 kg/h | $8,000 – $20,000+ |

🛒 Prices vary by manufacturer, features, and shipping fees.

Common Applications of Garlic Peeling Machines

- Food processing plants

- Ready-to-cook meal manufacturers

- Frozen garlic products

- Garlic paste, powder, and sauce factories

- Spice and seasoning companies

Top Garlic Peeling Machine Manufacturers

When sourcing a garlic peeling machine, consider reputable suppliers known for quality and service:

- DT Food Machinery (China)

- Amazon or Alibaba B2B platforms for small machines

Always request:

- Warranty terms

- After-sales support

- CE or ISO certifications

- Customization options

Frequently Asked Questions (FAQ)

Q: Does the machine damage the garlic?

A: High-quality machines maintain a low damage rate (less than 5%) and preserve the shape of the cloves.

Q: Can the machine peel wet garlic?

A: Dry air machines work best with dry garlic. If garlic is wet, use an air dryer beforehand.

Q: How much noise does it produce?

A: Most noise comes from the air compressor. Use low-noise compressors for indoor use.

Q: What maintenance is required?

A: Regular cleaning, air filter checks, and silicone ring replacements.

Q: Can I peel garlic without an air compressor?

A: No. Dry-type peeling machines require compressed air to function. Roller types may work without it but are less efficient.

Conclusion

A garlic peeling machines is a valuable asset for any business involved in food preparation or processing. With proper selection based on your production needs, you can save labor, ensure food hygiene, and increase efficiency. Whether you’re a small-scale entrepreneur or managing a large food processing unit, the right garlic peeler can significantly streamline your operations.

Before buying, assess the technical specs, compatibility with air systems, and after-sales service offered by the manufacturer. And always match the machine’s capacity with your daily garlic demand.