Cuando las empresas alimentarias se expanden o empiezan a automatizar la producción, una de las primeras preguntas que surge es: “¿Cuál es el precio de una máquina automática de rollitos de primavera??"

Esta es una pregunta muy práctica, pero la respuesta depende de varios factores clave, como la capacidad., nivel de automatización, tipo de llenado, marca, país natal, y accesorios opcionales. En este artículo, exploraremos todo lo que necesitas saber sobre Precios de la máquina automática de rollitos de primavera., Cómo elegir el modelo adecuado para tu negocio., y qué debes buscar antes de hacer una inversión.

🏭 1. Entendiendo la máquina automática de rollitos primavera

Un máquina automática de rollitos de primavera Es una pieza especializada de equipo de procesamiento de alimentos diseñada para producir rollitos de primavera en grandes cantidades con un tamaño constante., forma, y sabor. Realiza múltiples pasos automáticamente., incluido:

- Formación de envoltura

- alimentación de llenado

- Laminado y sellado

- Conteo y embalaje (opcional)

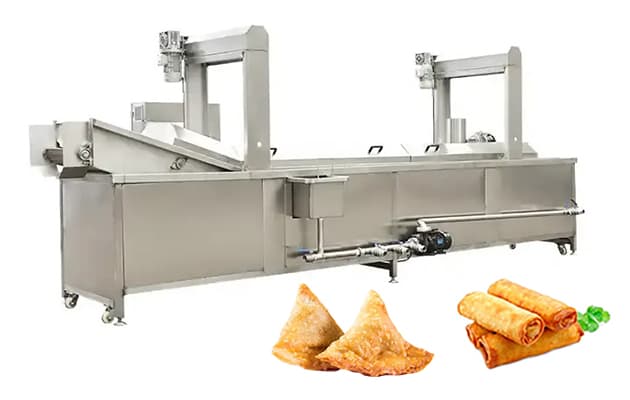

Es ampliamente utilizado en fábricas que producen alimentos congelados., bocadillos, o comidas listas para comer. Estas máquinas pueden producir no sólo rollitos de primavera al estilo chino sino también rollitos vietnamitas., samosas, rollitos de primavera, e incluso panecillos según la configuración.

💰 2. Rango general de precios de las máquinas automáticas de rollitos primavera

El precio El rendimiento de una máquina automática de rollitos de primavera puede variar mucho según su nivel de automatización y capacidad de producción.. A continuación se muestra una referencia general.:

| Tipo de máquina | Capacidad (PC/hora) | Gama de precios (Dólar estadounidense) | Nivel de automatización |

|---|---|---|---|

| Pequeña máquina semiautomática para rollitos de primavera | 500–1500 | $2,000–$5,000 | Llenado manual |

| Máquina automática compacta para rollitos de primavera | 2000–4000 | $6,000- $ 10,000 | Formación automática de envolturas |

| Máquina automática industrial para rollitos de primavera | 5000–8000 | $10,000–$18,000 | Totalmente automático |

| Gran línea de producción con freidora. & embalaje | 8000–15000+ | $20,000–$60,000+ | Totalmente integrado |

👉 Resumen:

- Los pequeños comercios o restaurantes locales pueden empezar con un modelo semiautomático de bajo coste.

- Las fábricas medianas deberían considerar máquinas totalmente automáticas para reducir los costos laborales..

- Los grandes fabricantes de alimentos suelen invertir en líneas de producción integradas.

⚙️ 3. Factores clave que afectan el precio de la máquina

3.1 Capacidad de producción

Cuanto mayor sea la producción (piezas por hora), cuanto mayor sea el precio. Las máquinas diseñadas para uso industrial requieren motores más potentes, sistemas PLC avanzados, y marcos de acero inoxidable para soportar el funcionamiento continuo.

3.2 Nivel de automatización

Una máquina semiautomática sólo automatiza la fabricación de envoltorios, mientras un máquina de rollitos de primavera completamente automática realiza todo el proceso, incluido el llenado, plegable, y sellado. Esta diferencia puede duplicar o incluso triplicar el precio..

3.3 Sistema de llenado y material

Si tus rollitos de primavera contienen rellenos mixtos como verduras, fideos de vidrio, o carne picada, necesitarás un sistema de llenado personalizado. Los sistemas de llenado neumáticos con control preciso del volumen son más caros que los manuales.

3.4 Tecnología de formación de envolturas

Algunos fabricantes utilizan tambores calefactores.; otros utilizan cintas de horneado continuas. Máquinas con ajuste automático de espesor., control de temperatura, y el revestimiento antiadherente generalmente cuesta más.

3.5 Material de construcción

De grado alimenticio 304 acero inoxidable es estándar, pero si todo el marco y el sistema de alimentación utilizan acero inoxidable, el costo será mayor. Esto garantiza higiene y durabilidad a largo plazo..

3.6 Marca y país de origen

maquinas hechas en Porcelana y Taiwán A menudo son más rentables que los fabricados en Japón o Europa.. Sin embargo, marcas chinas líderes como Máquina de alimentos DT combinar calidad y asequibilidad, haciéndolos ideales para compradores internacionales.

3.7 Equipo opcional

Agregar equipo adicional como un freidora, transportador de enfriamiento, máquina de embalaje, o Congelador IQF aumentará significativamente la inversión total.

🔍 4. Ejemplos de precios típicos (2025 Actualizar)

Para que tengas una idea más clara, aquí son aproximados precios de mercado a partir de 2025:

| Modelo | Capacidad | Características | Precio estimado |

|---|---|---|---|

| DT-SRM2000 | 2000 PC/hora | Diseño compacto, envolvedora automática, llenado manual | $6,000- $ 8,000 |

| DT-SRM4000 | 4000 PC/hora | Formado completamente automático, plegable, caza de focas | $10,000–$12,000 |

| DT-SRM8000 | 8000 PC/hora | Control PLC industrial, llenado automático, cinturón doble | $15,000- $ 20,000 |

| Línea completa DT | 12000 PC/hora | Línea completa con freidora, transportador, embalaje | $35,000–$60,000+ |

💡 Nota: Estos son precios aproximados de fábrica. (ExW). Costos adicionales como envío., aduanas, y la instalación varían según el país.

🧩 5. Qué está incluido en el precio?

Cuando recibe una cotización de un fabricante profesional como Máquina de alimentos DT, El precio estándar suele incluir:

- Máquina formadora principal de rollitos de primavera

- Sistema de calefacción (gas o electrico)

- Panel de control con PLC

- Tolva de llenado & boquillas

- Repuestos y herramientas

- Manual de operación

- Garantía de un año

Los elementos opcionales pueden incluir:

- Freidora continua

- Transportador de enfriamiento

- Contador automático

- maquina empacadora

Antes de confirmar el pedido, Siempre verifique lo que está incluido y si la instalación o la capacitación son parte de la oferta..

🌍 6. Comparación de precios por país

| País | Nivel de precio | Características notables |

|---|---|---|

| Porcelana | ★★★ Asequible | Fuerte desempeño, diseño personalizable |

| Japón | ★★★★★ Caro | Precisión superior, adecuado para fábricas de alimentos congelados de alta gama |

| Europa | ★★★★☆ Alto | Cumple con las normas CE y HACCP |

| India | ★★ Bajo | Funciones básicas, automatización limitada |

| Tailandia / Vietnam | ★★★ Moderado | Máquinas chinas a menudo renombradas |

Para la mayoría de los compradores, Máquinas para rollitos de primavera fabricadas en China proporcionar el mejor equilibrio entre precio, calidad, y servicio postventa.

🧮 7. Costos adicionales a considerar

Al planificar su presupuesto, no olvides incluir:

- Envío y carga: Dependiendo de la ubicación, el transporte marítimo puede costar entre 500 y 2000 dólares.

- Derechos de aduana e impuestos de importación: Varía por país (5%–20%).

- Conversión de voltaje o tipo de enchufe: Puede requerir ajustes para los estándares locales..

- Capacitación del operador: Algunos fabricantes ofrecen formación online gratuita..

- Mantenimiento y Repuestos: Típicamente de bajo costo para las máquinas chinas..

Todos estos factores afectan su costo total de inversión, no sólo el precio de la máquina.

🧠 8. Cómo elegir la máquina automática de rollitos primavera adecuada

Al comparar precios, No se centre sólo en el costo: evalúe valor y rendimiento. Aquí hay consejos prácticos.:

- Defina sus necesidades de capacidad:

Elija un modelo que cumpla con sus objetivos de producción pero que deje espacio para crecer. - Verificar los materiales de la máquina:

Asegúrese de que todas las piezas que entran en contacto con los alimentos estén hechas de 304 acero inoxidable. - Confirmar compatibilidad de llenado:

Pregunta si tu relleno específico (verdura, carne, fideos de vidrio, etc.) se puede procesar sin problemas. - Solicite un video o una demostración en vivo:

Fabricantes confiables como DT Food Machine ofrecen videos de prueba o demostraciones en línea. - Pregunte sobre el soporte posventa:

Garantía, disponibilidad de piezas de repuesto, y la guía remota son fundamentales para el uso a largo plazo. - Comparar la eficiencia energética:

Los modelos calentados por gas suelen ser más baratos de utilizar que los eléctricos..

🔧 9. Costo de mantenimiento y operación

Aunque el precio inicial es importante, el costo operativo también afecta tu rentabilidad.

Las máquinas automáticas de rollitos de primavera generalmente tienen bajos costos de mantenimiento si se usan correctamente. Los puntos clave de mantenimiento incluyen:

- Limpieza del tambor envolvedor después de cada lote

- Comprobación de desgaste de las cintas transportadoras

- Lubricar las piezas móviles con regularidad

- Reemplazo periódico de elementos calefactores.

El mantenimiento adecuado no sólo prolonga la vida útil de la máquina sino que también mejora la eficiencia de la producción, lo que le permite ahorrar dinero con el tiempo..

📈 10. Retorno de la inversión (ROI)

Calculemos un ejemplo simple de ROI:

- Costo de la máquina: $12,000

- Producción: 4000 PC/hora

- Producción diaria: 32,000 piezas (8 horas)

- Beneficio por pieza: $0.05

👉 Beneficio diario: 32,000 × 0.05 = $1,600/día

Puede recuperar el costo total en menos de 10 días de trabajo — haciendo de esta una de las inversiones con amortización más rápida en la industria alimentaria.

🤝 11. Por qué elegir DT Food Machine

Máquina de alimentos DT es un fabricante profesional de Máquinas automáticas de rollo de primavera y líneas de procesamiento de alimentos con años de experiencia exportando a Asia, Europa, el Medio Oriente, y sudamerica.

Ventajas de elegir DT Food Machine:

- Precios directos de fábrica

- Capacidad y tamaño personalizables

- Construcción de acero inoxidable

- Opciones de voltaje internacional

- 24-hora de soporte en línea

- Vídeos y manuales de funcionamiento gratuitos.

- Certificado CE y aprobado ISO

Ofrecemos máquinas independientes y líneas de producción de rollitos de primavera completamente automáticas., ayudando a los clientes a construir plantas eficientes de alimentos congelados en todo el mundo.

📦 12. Cómo obtener una cotización

Si estás interesado en saber exactamente Precio de la máquina automática de rollitos de primavera., simplemente contacte a nuestro equipo de ventas con estos detalles:

- Capacidad de producción deseada (PC/hora)

- Tipo de relleno que planeas usar

- Requisitos de voltaje y potencia.

- Necesidad de freidora o sistema de envasado.

- Puerto o país de destino

Dentro 24 horas, nuestro equipo preparará un cotización personalizada con especificaciones de la máquina, vídeos, y tiempo estimado de entrega.

📝 Precio de una máquina automática de rollitos de primavera

El Precio de una máquina automática de rollitos de primavera. rangos de $6,000 a $60,000+, dependiendo de la capacidad de producción, nivel de automatización, y equipo extra. Para la mayoría de las fábricas de alimentos de tamaño mediano, una máquina confiable en el $10,000- $ 20,000 el rango es ideal: equilibrar el costo, eficiencia, y valor a largo plazo.

Al elegir un fabricante de confianza como Máquina de alimentos DT, Puede garantizar no solo precios competitivos sino también una excelente calidad., servicio global, y soporte técnico.

Si está listo para actualizar su línea de producción o iniciar un nuevo negocio de rollitos de primavera congelados, un máquina automática de rollitos de primavera es la clave para una mayor productividad y rentabilidad.