La mantequilla de maní es una de las propagaciones más consumidas del mundo, popular por su textura cremosa, sabor rico, y valor nutricional. Desde fábricas de alimentos a gran escala hasta pequeñas empresas de procesamiento de maní, La demanda de equipos eficientes y confiables es cada vez mayor. At the heart of this industry lies the industrial máquina de hacer mantequilla de maní, a specialized piece of equipment designed to turn roasted peanuts into smooth, cremoso, or crunchy peanut butter at scale.

En esta guía completa, we will explore everything about the industrial peanut butter making machine: Cómo funciona, its features, parámetros técnicos, aplicaciones, and how to request a quotation (RFQ). Whether you are a food processing investor, un gerente de fábrica, or simply researching for your business, this article will help you understand why this machine is essential and how to choose the right one.

1. What Is an Industrial Peanut Butter Making Machine?

An industrial peanut butter making machine is a high-performance food processing machine designed to grind roasted peanuts into paste. It uses advanced grinding technology—often colloid mill or stone mill systems—to break down peanuts into very fine particles. The result is smooth, coherente, and hygienic peanut butter ready for packaging or further processing.

Unlike household blenders or small grinders, industrial machines are built for continuous operation, alto rendimiento, and compliance with international food safety standards. Se utilizan comúnmente en:

- Fábricas de mantequilla de maní

- Nut processing plants

- Snack food manufacturers

- Catering and large kitchens

- Empresas alimentarias orientadas a la exportación.

2. Why Choose an Industrial Peanut Butter Making Machine?

✅ High Capacity

Industrial machines are designed to produce hundreds of kilograms per hour, making them suitable for commercial production.

✅ Consistency and Quality

The advanced grinding systems guarantee a smooth texture and stable product quality, reducing variations between batches.

✅ Durability

Made from food-grade stainless steel, these machines are resistant to corrosion and built to last in heavy-duty environments.

✅ Versatility

Many models can process other nuts such as almonds, anacardos, semillas de sésamo, or even chickpeas to make tahini or hummus.

✅ Hygiene and Safety

Machines meet international food safety standards (ISO, Ceñudo, or FDA-approved designs), ensuring safe production.

3. Working Principle of a Peanut Butter Machine

Most industrial peanut butter machines use colloid mill technology. The principle is simple but effective:

- Alimentación – Roasted peanuts are fed into the hopper.

- Molienda – The machine uses a high-speed rotating stator and rotor to apply strong shearing, molienda, y vibración de alta frecuencia.

- Homogeneización – The particles are reduced to 2–50 microns, creating a smooth paste.

- Enfriamiento – Some machines use water-cooling systems to prevent overheating and preserve the flavor.

- Descargar – The finished peanut butter is collected and ready for packaging or mixing with additives (azúcar, sal, estabilizadores).

4. Technical Parameters of Industrial Peanut Butter Making Machine

Below is a general technical specification table. These parameters may vary depending on the model and manufacturer.

| Parámetro | Rango de especificaciones | Notas |

|---|---|---|

| Capacidad | 100 kg/h - 2000 kg/hora | Depending on model size |

| Fuerza | 4 KW - 75 kilovatios | Adjustable motor options |

| Voltaje | 220V / 380V / 415V, 50Hz/60Hz | Customized for regions |

| Fineness of Product | 2 - 50 micras | Ultra-fine grinding possible |

| Material | SUS 304 / SUS 316 acero inoxidable | De grado alimenticio, anticorrosión |

| Cooling Method | Water cooling or air cooling | Prevents overheating |

| Dimensiones | 600×400×900 mm up to 1200×700×1600 mm | Depende del modelo |

| Peso | 150 kilos – 1200 kilos | Heavy-duty construction |

| Sistema de control | Automático / semiautomático | With safety protections |

| Solicitud | Peanut, almendra, sésamo, anacardo, garbanzos | Multi-purpose use |

These specifications ensure flexibility for different scales of production, from small factories to large multinational food processors.

5. Types of Industrial Peanut Butter Machines

There are different machine designs based on grinding technology:

5.1 Colloid Mill Peanut Butter Machine

- Most common type.

- High-speed rotor and stator create strong shearing.

- Produces ultra-fine and consistent paste.

5.2 Stone Mill Peanut Butter Machine

- Uses natural stone grinders.

- Produces a more traditional taste.

- Lower output compared to colloid mills.

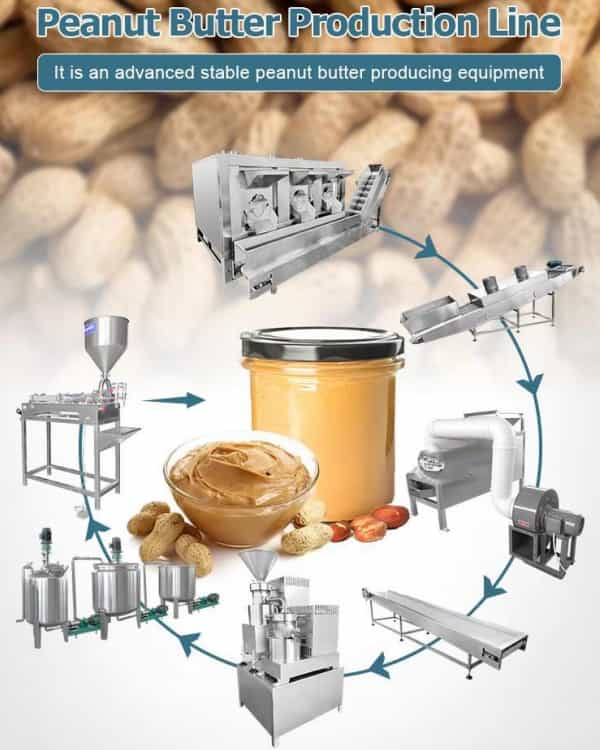

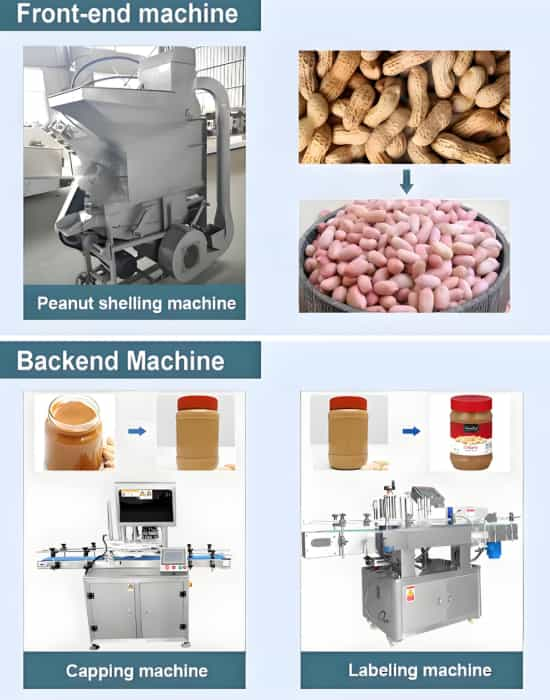

5.3 Combined Processing Line

- Incluye asar, peladura, molienda, Mezcla, and filling.

- Full turnkey peanut butter production line.

- Adecuado para grandes fábricas.

6. Industrial Applications

The machine is not limited to peanuts. It is widely used in multiple industries:

- Industria alimentaria: Manteca de cacahuete, almond paste, sésamo tahini, pasta de chile, salsas.

- Health Food: Natural nut butters without additives.

- Confitería: Filling for chocolate, galletas, and snacks.

- Export Products: Packaged peanut butter for supermarkets.

7. Guía de instalación y funcionamiento

Paso 1: Posicionamiento

Place the machine on a flat, superficie estable. Ensure proper alignment with other production equipment.

Paso 2: Power Connection

Connect to the appropriate power source (220V/380V/415V). Verify grounding for safety.

Paso 3: Water Cooling System

If using a water-cooled machine, connect the inlet and outlet hoses for circulation.

Paso 4: Feeding Peanuts

Feed roasted peanuts gradually into the hopper. Avoid unroasted or wet peanuts.

Paso 5: Molienda

Adjust the gap between rotor and stator to achieve the desired fineness.

Paso 6: Recopilación

Collect the finished peanut butter in stainless steel containers for packaging.

Paso 7: Limpieza

Flush with hot water after production. Use food-grade detergent for deep cleaning.

8. Consejos de mantenimiento

- Regularly check bearings and lubricate if necessary.

- Clean immediately after production to avoid residue.

- Replace worn grinding parts (rotor, estator, or stones).

- Inspect electrical components monthly.

- Avoid overloading the hopper.

Proper maintenance ensures machine longevity and consistent product quality.

9. Cómo elegir la máquina adecuada

When purchasing an industrial peanut butter making machine, considerar:

- Capacidad de producción – Match machine output to your expected daily demand.

- Calidad de material – Ensure SUS 304 o 316 stainless steel for hygiene.

- Consumo de energía – Energy-efficient models reduce costs.

- Soporte para después de las ventas – Choose a manufacturer with technical support and spare parts availability.

- Presupuesto – Balance between machine cost and production benefits.

10. Solicitud de cotización (RFQ) Guide

When contacting a supplier for an RFQ, provide clear details to receive accurate pricing.

Sample RFQ Questions & Respuestas:

Q1: What capacity do you require?

A1: Ejemplo: 500 kg/h peanut butter production.

Q2: Do you need a standalone grinder or a full production line?

A2: Ejemplo: Full line including roasting, peladura, molienda, Mezcla, and filling.

Q3: What is your preferred power supply?

A3: Ejemplo: 380V, 50Hz, three-phase.

Q4: Do you need water cooling or air cooling?

A4: Ejemplo: Water cooling system preferred for large-scale production.

Q5: What type of peanut butter do you plan to produce?

A5: Ejemplo: Creamy peanut butter with optional crunchy variety.

Q6: What is your packaging requirement?

A6: Ejemplo: 200gramo, 500gramo, and 1kg jars.

Q7: Do you need OEM/branding support?

A7: Ejemplo: Sí, custom labeling and logo.

Q8: What certifications do you require?

A8: Ejemplo: CE and FDA approval for export to EU and USA.

Q9: What is your budget range?

A9: Ejemplo: $8,000 - $25,000 depending on machine size.

Q10: What is your delivery timeline?

A10: Ejemplo: Dentro 45 days after payment.

Providing this information helps suppliers quote accurately and saves time in negotiation.

11. An Industrial Peanut Butter Making Machine Price

The price varies depending on size, características, and country of origin:

- En pequeña escala (100–300 kg/h): $3,000 - $7,000

- Mediano (300–1000 kg/h): $8,000 - $20,000

- A gran escala (1000–2000 kg/h): $20,000 - $60,000

- Full automatic lines: $50,000 - $200,000

Factors influencing price include:

- Stainless steel grade (304 VS 316)

- marca de motor (local vs international)

- Nivel de automatización

- Necesidades de personalización

12. Future of Peanut Butter Processing

With the global demand for healthy snacks and plant-based protein, peanut butter consumption is increasing. Industrial machines will continue to evolve with:

- Automatización & IoT for smart production.

- Energy-efficient motors to reduce costs.

- Multi-nut capabilities for wider product variety.

- Compact designs for small factories.

Investing in a modern industrial peanut butter making machine is not just about meeting demand—it’s about staying competitive.

Industrial peanut butter making machine

El industrial peanut butter making machine is an essential investment for businesses aiming to enter or expand in the nut processing industry. With high capacity, advanced grinding technology, and hygienic stainless steel design, it ensures consistent production of high-quality peanut butter.

From understanding technical parameters to preparing an RFQ, careful planning will help you choose the right equipment for your production needs. Whether you want a standalone grinder or a fully automated peanut butter production line, modern machines offer flexibility, eficiencia, y rentabilidad.

If you are ready to scale your peanut butter business, now is the time to invest in reliable equipment and partner with a trusted manufacturer.