Introducción

El chocolate comienza su vida en el humilde grano de cacao.. Pero antes de que se vuelva suave, rico manjar que todos conocemos, El frijol debe pasar por varias etapas de transformación, una de las más importantes es molienda. El maquina trituradora de cacao es una pieza clave del equipo en este proceso, responsable de convertir las semillas de cacao tostadas en fino licor de chocolate.

Para fabricantes de chocolate, pequeños productores, e incluso chocolateros artesanales, entender cómo funciona una máquina trituradora de cacao, sus usos, y sus beneficios pueden mejorar drásticamente la calidad y eficiencia del producto.. En este artículo, Exploraremos todo lo que necesita saber sobre la máquina trituradora de cacao, desde su principio de funcionamiento y aplicaciones hasta especificaciones técnicas y consejos de selección..

1. ¿Qué es una máquina trituradora de cacao??

A maquina trituradora de cacao, a veces referido como un melanger de chocolate o máquina de molienda de cacao, Se utiliza para moler finamente semillas de cacao tostadas hasta obtener una pasta suave conocida como licor de cacao o masa de cacao. Esta etapa es crucial en el proceso de elaboración del chocolate., ya que la molienda determina la textura final, suavidad, y perfil de sabor del chocolate.

Estas máquinas pueden variar desde pequeñas unidades de mesa diseñadas para fabricantes de chocolate domésticos o de pequeña escala hasta grandes molinillos industriales utilizados en fábricas de chocolate profesionales..

Típicamente, Una máquina trituradora de cacao consta de:

- A tambor o cámara de acero inoxidable

- Piedras de amolar o hojas de acero

- Motor y caja de cambios

- Sistema de control de temperatura

El proceso de molienda descompone las semillas de cacao., liberando su manteca de cacao natural y transformándolas en una crema, Pasta homogénea lista para refinar y conchar..

2. ¿Cómo funciona una máquina trituradora de cacao??

El principio de funcionamiento de una máquina trituradora de cacao es simple pero efectivo.. Las semillas de cacao tostadas se introducen en la cámara de molienda., donde dos pesadas piedras de moler o cuchillas los aplastan y cortan continuamente.

Aquí está el proceso paso a paso.:

- Alimentación

Las semillas de cacao tostadas y aventadas se colocan en la tolva.. - Molienda y corte

Las piedras giratorias o las cuchillas de acero inoxidable muelen las puntas., liberar manteca de cacao y convertir la mezcla en una pasta espesa. - Refinación continua

La máquina continúa moliendo durante varias horas., refinar el tamaño de partícula a 20 micras o menos. - Regulación de temperatura

Algunos molinillos de cacao avanzados incluyen sensores de temperatura y sistemas de refrigeración por agua para evitar el sobrecalentamiento y preservar el sabor.. - Descargar

Una vez conseguida la finura deseada, el licor de cacao se descarga para su posterior procesamiento en barras de chocolate, polvo, u otros productos del cacao.

3. Principales usos de una máquina trituradora de cacao

El uso primario de una máquina trituradora de cacao es moler semillas de cacao en licor de chocolate, pero también puede servir para otros propósitos en la industria alimentaria..

3.1 Producción de chocolate

Las máquinas trituradoras de cacao son esenciales para hacer todo tipo de chocolate: negro, leche, o blanco. Después de moler, la masa de cacao se mezcla con azúcar, leche en polvo, y manteca de cacao para producir chocolate con un rico, textura sedosa.

3.2 Extracción de manteca de cacao

El licor de cacao finamente molido se prensa para extraer la manteca de cacao., un ingrediente esencial para el chocolate, productos cosméticos, y productos farmacéuticos.

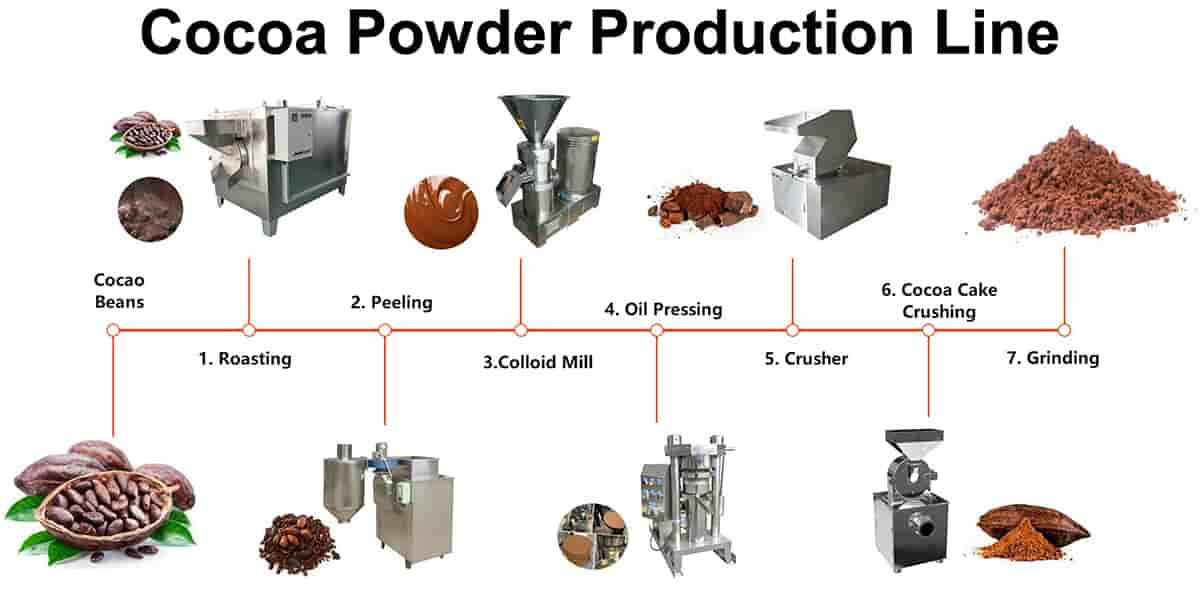

3.3 Fabricación de cacao en polvo

Después de extraer la manteca de cacao, el sólido restante se seca y se muele para obtener cacao en polvo que se utiliza para hornear, bebidas, y postres.

3.4 Molienda de nueces y semillas

Algunas máquinas trituradoras de cacao versátiles también pueden moler maní, almendras, sésamo, u otras nueces: ideal para hacer mantequillas o pastas de nueces.

3.5 Procesamiento de bebidas y postres

En fábricas de bebidas, Los molinillos de cacao se utilizan para hacer bases de chocolate caliente., salsas de chocolate, y jarabes.

4. Ventajas de utilizar una máquina trituradora de cacao

Invertir en una trituradora de cacao de calidad ofrece varios beneficios para los productores de chocolate:

4.1 Tamaño de partícula consistente

La molienda uniforme garantiza una sensación suave en la boca y una textura premium en el producto final de chocolate..

4.2 Desarrollo de sabor mejorado

La molienda continua libera la manteca de cacao de manera uniforme, permitiendo una mejor integración del sabor durante el conchado.

4.3 Eficiencia y productividad

Las máquinas modernas pueden moler grandes lotes de forma continua, ahorrar tiempo y costos de mano de obra.

4.4 Diseño higiénico y duradero

La mayoría de los molinillos de cacao industriales están hechos de acero inoxidable apto para uso alimentario., fácil de limpiar y resistente a la corrosión.

4.5 Eficiencia energética

Los modelos avanzados vienen con motores que ahorran energía y sistemas de control de temperatura., reduciendo los costos operativos.

5. Estructura y componentes de una máquina trituradora de cacao

Una máquina trituradora de cacao típica consta de varias partes principales.:

| Componente | Función |

|---|---|

| Cámara de molienda | Sostiene las semillas de cacao y garantiza una molienda consistente. |

| Piedras o cuchillas de amolar | Cortar y triturar las puntas en partículas finas. |

| Motor | Proporciona potencia mecánica para moler. |

| Caja de cambios | Controla la velocidad de rotación y el par. |

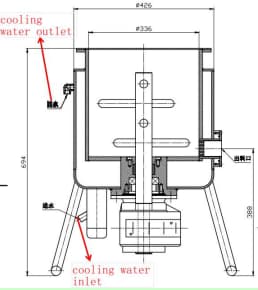

| Sistema de enfriamiento | Mantiene una temperatura de molienda estable |

| Panel de control | Permite ajustes y seguimiento de la operación. |

| Válvula de descarga | Libera licor de cacao terminado |

6. Parámetros técnicos (Ejemplo: Máquina de Alimentos DT Modelo CGM-50)

| Modelo | CGM-50 |

|---|---|

| Capacidad | 50 kg/hora |

| Fuerza | 7.5 kilovatios |

| Finura de molienda | ≤ 20 micras |

| Material | SUS304 acero inoxidable |

| Peso | 280 kilos |

| Voltaje | 380V / 50Hz |

| Tipo de enfriamiento | Refrigeración por agua |

| Dimensiones | 900 × 700 × 1200 milímetros |

Este modelo es adecuado para fabricantes de chocolate de pequeña y mediana escala que buscan alta eficiencia y rendimiento estable..

7. Cómo elegir la máquina trituradora de cacao adecuada

Al seleccionar una máquina trituradora de cacao para su negocio, Considere los siguientes factores:

- Capacidad de producción – Elija según su producción diaria o mensual.

- Finura de molienda – Cuanto más fino sea el molido, cuanto más suave sea la textura del chocolate.

- Material y durabilidad – Opte por componentes de acero inoxidable o aptos para uso alimentario..

- Control de temperatura – Previene el sobrecalentamiento, que puede arruinar el sabor.

- Facilidad de limpieza – Los bidones y piedras extraíbles simplifican el saneamiento..

- Servicio postventa – Consultar garantía, piezas de repuesto, y soporte técnico.

Si está iniciando un negocio de fabricación de chocolate, un molinillo de cacao semiautomático puede ser suficiente. Para fábricas de chocolate a gran escala, Se recomienda una trituradora continua completamente automática..

8. Consejos de mantenimiento y limpieza

El mantenimiento adecuado garantiza una larga vida útil de la máquina y una calidad de rectificado constante:

- Limpiar el tambor y las piedras después de cada lote..

- Evite sobrecargar el molinillo más allá de su capacidad nominal..

- Lubrique los rodamientos regularmente.

- Compruebe si hay desgaste en las correas del motor y en la caja de cambios..

- Mantenga el sistema de enfriamiento funcional.

- Almacenar en un ambiente seco y limpio..

El mantenimiento regular puede prolongar la vida útil de la amoladora varios años.

9. Rango de precios de la máquina trituradora de cacao

El precio de una maquina trituradora de cacao depende de la capacidad, nivel de automatización, y material.

| Tipo de máquina | Capacidad (kg/hora) | Aproximadamente. Gama de precios (Dólar estadounidense) |

|---|---|---|

| Molinillo a pequeña escala | 10–30 kg/h | $800 - $2,500 |

| Molinillo de mediana escala | 50–100 kg/h | $3,000 - $8,000 |

| Molinillo industrial | 200–500 kg/h | $10,000 - $25,000+ |

Los precios pueden variar dependiendo de características adicionales como control de temperatura., refrigeración por agua, y automatización PLC.

10. ¿Por qué elegir DT Food Machine como su proveedor de máquinas trituradoras de cacao?

DT Food Machine Co., Limitado. es un fabricante profesional de equipos de procesamiento de cacao y fabricación de chocolate con más de 15 Años de experiencia.

10.1 Fabricación de calidad

Todas las máquinas están hechas de acero inoxidable de alta calidad y cumplir con Normas CE e ISO, garantizando durabilidad y seguridad alimentaria.

10.2 Personalización disponible

Ofrecemos maquinas trituradoras de cacao personalizadas para adaptarse a su capacidad específica, Voltaje, y necesidades de diseño.

10.3 Apoyo técnico

DT Food Machine proporciona guía de instalación completa, servicio postventa, y repuestos para mantener su producción funcionando sin problemas.

10.4 Exportación Global

Nuestras máquinas trituradoras de cacao se exportan a más de 40 países, incluyendo los EE.UU., México, Perú, Indonesia, y Ghana.

11. Preguntas frecuentes (Preguntas frecuentes)

Q1: ¿Se puede utilizar la máquina trituradora de cacao para otros frutos secos??

Sí, puede moler maní, almendras, sésamo, y anacardos con excelente suavidad.

Q2: ¿Qué tan fino muele las semillas de cacao??

Puede alcanzar un tamaño de partícula de 15 a 20 micrones., ideal para una textura suave del chocolate.

Q3: ¿Cuánto tiempo dura el proceso de molienda??

Suele tardar entre 6 y 12 horas, dependiendo de la finura deseada y del tamaño del lote.

Q4: ¿Proporcionas repuestos??

Sí, DT Food Machine proporciona repuestos completos y kits de mantenimiento para todos los modelos.

Q5: ¿Puedo personalizar la capacidad de la máquina??

Absolutamente. Podemos diseñar máquinas de 10 kg/h hasta 1000 kg/h según su escala de producción.

Máquina trituradora de cacao

A maquina trituradora de cacao es el corazón de la producción de chocolate: transformar las semillas de cacao en suaves, rico licor de cacao listo para refinar. Tanto si eres un pequeño artesano como un gran chocolatero industrial, elegir el molinillo adecuado afectará directamente la calidad de su producto, sabor, y eficiencia.

Entendiendo cómo funciona la máquina., sus aplicaciones, y mantenimiento, puede optimizar su proceso de producción y garantizar una consistencia, resultados de alta calidad.

Si estas buscando un fabricante confiable de maquinas trituradoras de cacao, Máquina de alimentos DT ofrece tecnología avanzada, diseño duradero, y servicio profesional para ayudarle a hacer crecer su negocio de chocolate.