Introduction

Chocolate is one of the world’s most beloved foods, but few consumers stop to think about the technology and equipment that transforms cocoa beans into the smooth, delicious chocolate products they enjoy. At the heart of modern chocolate production lies the chocolate grinding machine, a piece of equipment designed to refine cocoa nibs, sugar, milk powder, and other ingredients into a fine, smooth paste. This machine plays a critical role in determining the texture, flavor, and quality of chocolate, making it indispensable in both artisanal workshops and industrial-scale chocolate factories.

here,we will provide a comprehensive look into what a chocolate grinding machine is, how it works, its types, features, technical specifications, and its importance in the chocolate-making process. By the end, you’ll understand why choosing the right chocolate grinding machine is essential for chocolate producers, from small-scale businesses to global manufacturers.

What is a Chocolate Grinding Machine?

A chocolate grinding machine is specialized food processing equipment that grinds cocoa nibs and other ingredients into a uniform, fine chocolate mass. The machine uses mechanical force to crush, refine, and homogenize ingredients, breaking them down into particles small enough to achieve the smooth texture associated with high-quality chocolate.

Grinding is a key stage in chocolate production because it influences:

- Mouthfeel: Smooth chocolate has particle sizes below 30 microns.

- Flavor release: Smaller particles enhance flavor perception.

- Processing stability: Well-refined chocolate is easier to temper, mold, and use in confections.

Without efficient grinding, chocolate would feel coarse and gritty, drastically reducing consumer appeal.

The Role of Chocolate Grinding in the Production Process

Before diving into the machinery itself, it’s helpful to understand where grinding fits within the broader chocolate production line:

- Roasting – Cocoa beans are roasted to develop flavor and reduce moisture.

- Cracking & Winnowing – The roasted beans are cracked and husks removed, leaving cocoa nibs.

- Grinding – Cocoa nibs are ground into cocoa liquor using a chocolate grinding machine.

- Mixing & Refining – Cocoa liquor is combined with sugar, milk, and other ingredients, then refined.

- Conching – The chocolate mass is further aerated and refined for flavor and texture.

- Tempering & Molding – The chocolate is crystallized correctly and shaped into bars or other products.

The grinding stage is pivotal because it determines whether the cocoa liquor achieves the proper consistency for further processing.

Types of Chocolate Grinding Machines

Several types of chocolate grinding machines are used in the industry, each with unique advantages depending on scale, production needs, and desired product characteristics.

1. Ball Mill Chocolate Grinder

- Uses rotating balls inside a drum to crush and refine ingredients.

- Produces very fine chocolate mass (particle size <20 microns).

- Widely used in industrial chocolate factories.

- Benefits: High efficiency, continuous processing, consistent results.

2. Stone Grinder (Melanger)

- Traditional method using granite stones to grind nibs and sugar.

- Favored by artisanal and bean-to-bar chocolate makers.

- Provides excellent flavor development due to slow grinding.

- Benefits: Natural processing, enhanced aroma, small-batch flexibility.

3. Roller Refiners

- Uses multiple rollers to refine chocolate mass.

- Produces extremely fine particles.

- Often paired with conches in large-scale production.

- Benefits: Very smooth chocolate texture, high-volume capacity.

4. Universal Grinder

- Combines grinding and conching in one machine.

- Suitable for medium-scale chocolate production.

- Benefits: Cost-effective, compact design, versatile use.

Working Principle of a Chocolate Grinding Machine

Though designs vary, most chocolate grinding machines operate using a few common principles:

- Ingredient Feeding – Cocoa nibs, sugar, and milk powder are fed into the machine.

- Crushing/Refining – Grinding media (balls, stones, or rollers) break down particles through shear force.

- Homogenization – Continuous mixing ensures even particle distribution.

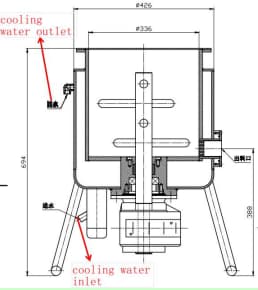

- Temperature Control – Cooling systems prevent overheating, which could affect flavor.

- Final Output – Chocolate liquor with a fine, uniform consistency.

Technical Parameters of Chocolate Grinding Machines

While specifications vary depending on machine type and size, here are some common parameters:

| Parameter | Typical Range |

|---|---|

| Capacity | 5 kg – 2000 kg per batch |

| Grinding Fineness | 15 – 30 microns |

| Motor Power | 1.5 kW – 75 kW |

| Voltage | 220V / 380V / 440V |

| Material | Stainless Steel (Food-grade) |

| Cooling System | Water-cooled or Air-cooled |

| Operating Temperature | 45°C – 75°C |

These technical specifications help manufacturers choose a machine that meets their scale of production and desired chocolate quality.

Key Features of a Chocolate Grinding Machine

Modern chocolate grinding machines come with several important features:

- High Efficiency – Capable of reducing particle size quickly and evenly.

- User-Friendly Operation – Easy-to-use control panels with digital displays.

- Hygienic Design – Food-grade stainless steel for sanitary processing.

- Energy Efficiency – Optimized motors to reduce power consumption.

- Safety Mechanisms – Overload protection, emergency stop functions.

- Customizable Capacity – From small-scale laboratory units to industrial systems.

Advantages of Using a Chocolate Grinding Machine

- Consistent Quality – Achieves uniform fineness for smooth chocolate.

- Flavor Development – Proper grinding enhances cocoa’s natural flavors.

- Scalability – Suitable for both small craft chocolatiers and industrial manufacturers.

- Efficiency – Saves time compared to manual grinding methods.

- Flexibility – Machines can process dark, milk, and white chocolate formulations.

Applications of Chocolate Grinding Machines

Chocolate grinding machines are not limited to chocolate bars alone. They are used in:

- Chocolate truffles

- Chocolate coatings for confectionery

- Chocolate spreads

- Hot chocolate bases

- Compound chocolates for baking and candy-making

Additionally, some machines can process nuts, seeds, and other ingredients to create products like nut pastes or praline fillings.

Maintenance and Care

To ensure long-lasting performance, chocolate grinding machines require regular maintenance:

- Cleaning – Thoroughly clean after each batch to prevent contamination.

- Lubrication – Keep bearings and moving parts well-lubricated.

- Inspection – Regularly check grinding media, belts, and motors.

- Calibration – Adjust settings to maintain particle size consistency.

Proper care extends machine lifespan and ensures consistent product quality.

How to Choose the Right Chocolate Grinding Machine

When selecting a chocolate grinding machine, consider the following factors:

- Production Capacity – Small workshops may need 10–50 kg units, while factories require machines handling 500+ kg.

- Desired Fineness – Choose based on whether you need 20–30 micron smoothness or coarser textures.

- Type of Chocolate – Dark, milk, or white chocolate may require different settings.

- Budget – Machines range from affordable stone grinders to high-end industrial ball mills.

- After-Sales Support – Ensure the supplier provides training, spare parts, and maintenance services.

Future Trends in Chocolate Grinding Technology

The chocolate industry continues to evolve, and so does grinding technology. Some trends include:

- Automation & Digital Control – Smart machines with automatic adjustments.

- Energy-Saving Designs – Lower power consumption and higher efficiency.

- Compact Multi-Function Units – Combining grinding, refining, and conching.

- Sustainable Materials – Eco-friendly designs to reduce environmental impact.

- Customization – Machines designed to meet specific chocolate recipes and flavor profiles.

Conclusion: DT Food Machine – Your Trusted Chocolate Grinding Machine Manufacturer

The chocolate grinding machine is a cornerstone of chocolate production, transforming raw ingredients into smooth, delicious chocolate. Its role in achieving the perfect texture, flavor, and consistency cannot be overstated. From small artisanal chocolate makers using stone grinders to large-scale producers employing ball mills, the right machine ensures efficiency, quality, and customer satisfaction.

At DT Food Machine, we are proud to be a leading manufacturer and supplier of chocolate grinding machines. With years of expertise in food machinery, we provide a wide range of grinding solutions tailored to the needs of different producers. Our machines are designed with precision engineering, durable materials, and user-friendly controls to ensure consistent performance. Whether you are a bean-to-bar chocolatier or an industrial chocolate factory, DT Food Machine offers reliable, high-quality equipment to elevate your chocolate production.

Choosing DT Food Machine means choosing innovation, durability, and unmatched after-sales service. Contact us today to learn more about our chocolate grinding machines and how we can help you achieve excellence in chocolate manufacturing.