Peanut butter has been one of the most iconic foods in the United States for more than a century. From household breakfast tables to commercial bakeries and large-scale food processors, American consumers demand consistently smooth, fresh, and high-quality peanut butter every day. As the market continues to expand—driven by health-conscious consumers, protein-rich diets, and rising snack food innovation—local peanut butter machine manufacturers need reliable equipment to keep up with production.

This is where the Peanut Butter Machine to the United States of America becomes essential. Whether you operate a small artisanal nut butter shop or a large-scale peanut butter production factory, investing in the right commercial peanut butter making machine dramatically improves efficiency, consistency, and profitability.

For insights for U.S. buyers—covering machine types, technical specifications, compliance requirements, installation tips, business applications, and purchasing advice. If you are sourcing peanut butter processing equipment from overseas, especially from professional manufacturers, this article is tailored for you.

1. The Growing Demand for Peanut Butter Machines in the United States

The United States is one of the world’s largest consumers and producers of peanut butter. According to market reports, the U.S. peanut butter industry exceeds $3 billion annually and continues to grow with new flavors, healthier versions, and on-the-go nut butter snacks.

Manufacturers across the U.S. increasingly require:

- High-capacity industrial nut butter grinders

- Consistent texture control (smooth, creamy, crunchy)

- Food-grade stainless steel equipment that meets FDA and USDA standards

- Energy-efficient machines suitable for continuous production

- Reliable overseas suppliers for cost-effective procurement

As businesses scale up production, choosing a professional peanut butter machine for the American market is necessary to stay competitive.

2. What Is a Peanut Butter Machine for the U.S. Market?

A peanut butter machine to the United States of America refers to food processing equipment designed to grind roasted peanuts into butter with adjustable fineness. These machines typically use:

- Colloid mill grinding technology

- High-precision stainless steel rotors

- Variable grinding speed

- Heat dissipation system to protect peanut aroma

- Easy-to-clean components for food safety compliance

Modern versions also support multi-function grinding for:

- Almond butter

- Cashew butter

- Pistachio paste

- Sesame tahini

- Hazelnut spread

- Walnut paste

- Macadamia butter

This flexibility allows U.S. businesses to expand their product range with one machine.

3. Types of Peanut Butter Machines for American Food Producers

3.1 Small Peanut Butter Grinder for Startups and Shops

Ideal for:

- Local nut butter businesses

- Farmers’ markets

- Grocery stores offering freshly-ground peanut butter

- Small food labs

Features:

- 20–50 kg/h capacity

- Simple operation

- Affordable price

- Zero floor drainage requirements

3.2 Medium-Scale Commercial Peanut Butter Machine

Suitable for:

- Commercial peanut butter brands

- Bakeries

- Restaurants

- Contract food manufacturers

Features:

- 100–250 kg/h output

- Adjustable grinding discs

- Support for crunchy or smooth textures

- Food-grade SS304 material

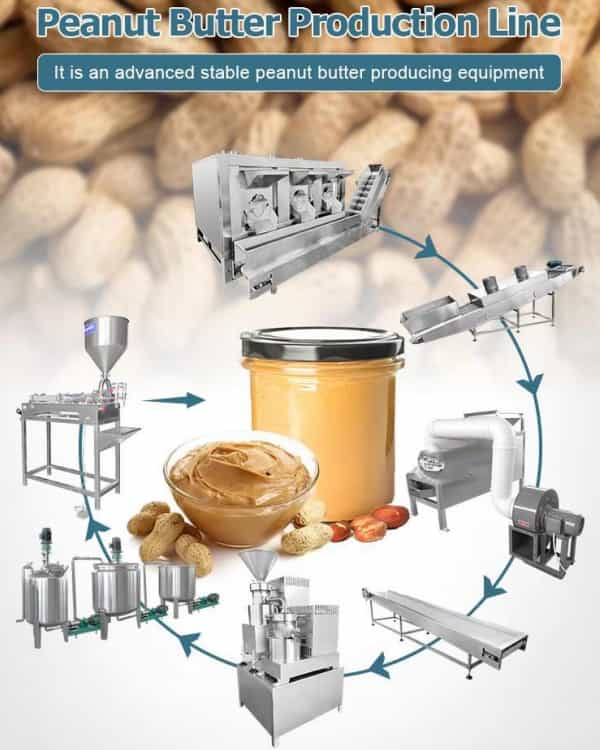

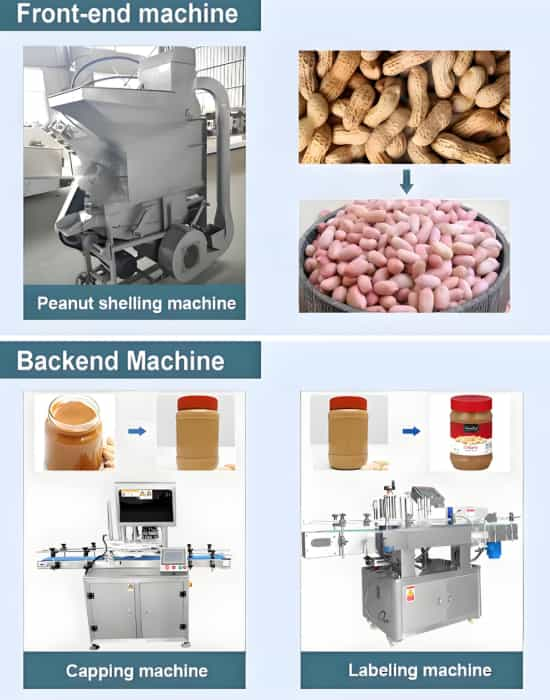

3.3 Industrial Peanut Butter Production Line for U.S. Factories

For:

- Peanut butter factories

- Nut spread manufacturing plants

- Co-packing companies

- Retail/wholesale snack manufacturers

The full production line includes:

- Peanut roasting machine

- Cooling conveyor

- Peeling machine

- Peanut butter grinder (colloid mill)

- Mixing and seasoning tank

- Storage tank

- Filling machine for peanut butter jars

Output: 500–2000 kg/h or more, depending on factory needs.

4. Key Features to Look for When Buying a Peanut Butter Machine in the United States

To ensure your investment is suitable for American food regulations and business requirements, focus on the following:

4.1 Food-Grade Stainless Steel

A must for U.S. buyers. Machines should use:

- SS304 for food contact parts

- SS316L available for higher hygiene environments

4.2 FDA / CE / UL Compliance Support

While FDA does not certify machines directly, all materials must comply with FDA food-contact regulations.

UL certification is often required by American factories for insurance and safety.

4.3 Adjustable Fineness

Fineness should reach:

- 100–120 mesh for smooth peanut butter

- Coarse settings for crunchy butter

4.4 Continuous Operation & Low Temperature Rise

Overheating reduces peanut butter flavor. A high-quality machine includes:

- Circulating water cooling

- High-speed rotor motor with stable performance

4.5 Easy to Clean & Maintain

Look for:

- Tool-free disassembly

- CIP-compatible (Clean-In-Place) designs

- Smooth internal surfaces

5. Technical Parameters (General Reference for U.S. Buyers)

| Model | Capacity (kg/h) | Power (kW) | Voltage Option | Material | Fineness |

|---|---|---|---|---|---|

| DT-50 | 50 kg/h | 1.5 kW | 110V / 220V | SS304 | 100–120 mesh |

| DT-100 | 100 kg/h | 7.5 kW | 220V / 380V | SS304 | 100–120 mesh |

| DT-200 | 200 kg/h | 11 kW | 380V | SS304 | 100–120 mesh |

| DT-500 | 500 kg/h | 22 kW | 380V | SS304 | Ultra-fine grinding |

Note: All models can be customized for the United States electrical standards.

6. Compliance Requirements for Peanut Butter Machines in the U.S.

When importing a peanut butter making machine to the U.S., manufacturers should consider:

✔ Voltage Standards

- 110V 60Hz for small machines

- 220V / 380V 60Hz for factories

✔ UL Electrical Safety (Optional but Recommended)

Reduces factory insurance cost.

✔ FDA Food-Contact Material Compliance

All parts touching peanut paste must be stainless steel, non-toxic, and corrosion-resistant.

✔ USDA Hygiene Requirements

Smooth surfaces, easy cleaning, and removable components.

Working with suppliers familiar with U.S. import standards ensures smooth customs inspection.

7. Applications of Peanut Butter Machines in the U.S. Food Industry

7.1 Peanut Butter Manufacturing Companies

Produce smooth, crunchy, or flavored butter like:

- Honey peanut butter

- Cinnamon peanut butter

- Chocolate peanut butter

7.2 Protein Snack Producers

Use peanut paste to make:

- Protein bars

- Nut energy balls

- Peanut-based spreads

7.3 Bakeries & Dessert Factories

For fillings in:

- Donuts

- Cookies

- Cakes

- Ice cream

7.4 Foodservice & Restaurants

Create homemade sauces like:

- Satay sauce

- Peanut dressing

- Peanut dipping paste

7.5 Private-Label & Co-Packing Facilities

Produce nut butters for multiple brands under one facility.

8. How to Choose the Right Peanut Butter Machine for Your US Business

8.1 Define Your Production Capacity

Ask:

- How many jars per day?

- Do you plan to expand next year?

Start with a scalable model.

8.2 Choose the Right Grinding Technology

Colloid mills provide:

- Uniform texture

- Long service life

- Low maintenance

8.3 Consider Customization for US Market

Including:

- 60Hz motors

- UL electrical components

- English operation manuals

- Spare parts stock

8.4 Evaluate Supplier Experience

Best suppliers offer:

- 10+ years manufacturing experience

- U.S. customer cases

- After-sales technical support

- Video/online installation guidance

8.5 Total Cost of Ownership (TCO)

Compare:

- Machine price

- Shipping

- Spare parts

- Electrical compatibility

- Production efficiency

9. Installation and Maintenance Guide for American Buyers

9.1 Installation Tips

- Ensure stable power supply

- Keep machine on level ground

- Connect circulating water (for cooling)

- Clean machine before first use

9.2 Maintenance Tips

- Apply peanut oil for internal lubrication before shutdown

- Rinse with warm water after production

- Check rotor clearance regularly

- Store in a dry environment

Proper maintenance ensures 8–10 years of reliable operation.

10. Why Import a Peanut Butter Machine to the USA Instead of Buying Locally?

Cost Advantage

Overseas suppliers often provide lower prices—40–60% cheaper than U.S. domestic machines.

Advanced Technology

Asian manufacturers lead in:

- Colloid mill precision

- Stainless steel craftsmanship

- Production line integration

Customizable Features

Manufacturers provide:

- Custom voltage

- Custom motors

- Custom peanut butter texture control

Fast International Delivery

Machines can be shipped by sea or air depending on urgency.

11. Case Examples: Peanut Butter Machines Delivered to American Clients

Case 1 – California Small Business

Bought DT-50 model

→ Now produces 300 jars/day

Case 2 – Texas Industrial Plant

Purchased DT-500 and full line

→ Supplies major supermarket chains

Case 3 – New York Organic Food Brand

Uses medium-scale grinder

→ Produces almond, cashew, and peanut butter

12. Final Buying Advice for U.S. Peanut Butter Manufacturers

- Choose the right capacity based on your business size

- Ensure material and electrical compliance for the U.S. market

- Work with experienced peanut butter machine exporters

- Confirm after-sales support and spare parts availability

A reliable peanut butter machine is the foundation of consistent, profitable, and scalable peanut butter production.

Conclusion: DT Food Machine – Professional Supplier of Peanut Butter Machine to the United States of America

If you are looking for a Peanut Butter Machine to the United States of America, DT Food Machine is a trusted global manufacturer specializing in exporting commercial peanut butter making machines, industrial nut butter grinders, and full peanut butter production lines to the U.S. market.

We provide:

- U.S. voltage customization (110V/220V/380V 60Hz)

- FDA-compliant materials

- UL electrical components

- Technical support and installation guidance

- Competitive pricing for American customers

DT Food Machine has successfully exported peanut butter machines to multiple states across the USA and continues to support both small producers and large factories.