Ice cream cones are an iconic symbol of summer, fun, and dessert indulgence. But behind every perfectly shaped cone lies a sophisticated piece of equipment—the ice cream cone machine. As global demand for ice cream continues to rise, businesses seek reliable ice cream cone machine manufacturers to supply high-performance, automated solutions. This comprehensive guide explores the world of cone-making machines, variations, applications, and how to choose the right manufacturer.

In the final section, we introduce DT Food Machine, a professional ice cream cone machine manufacturers and supplier trusted by clients around the globe.

Commercial Ice Cream Cone Machine Suppliers

When it comes to large-scale production, commercial ice cream cone machine suppliers play a crucial role. These companies offer heavy-duty machines designed to meet high-output requirements in factories, food processing units, and large-scale ice cream businesses.

Features of Commercial Cone Machines

- High Production Capacity: Commercial machines can produce thousands of cones per hour.

- Automated Operation: Full automation reduces labor costs and ensures uniform quality.

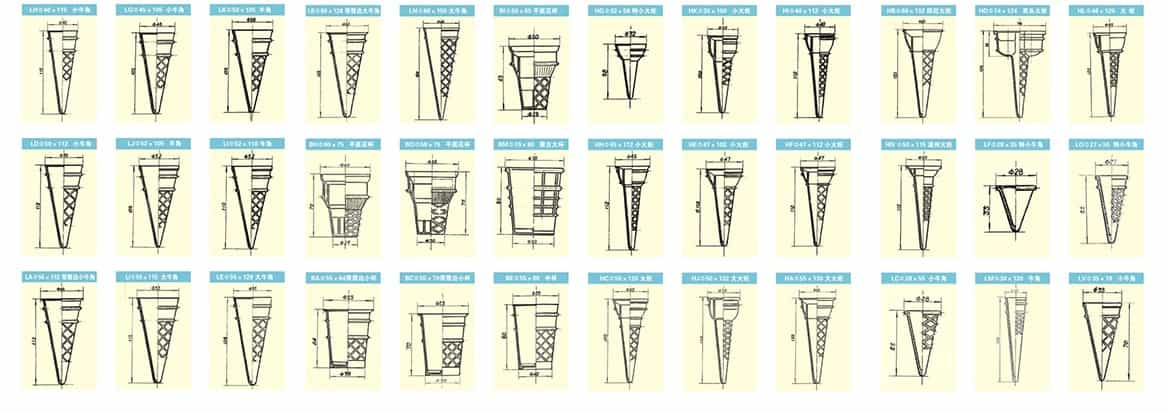

- Custom Molds: Manufacturers can provide cone molds of various shapes and sizes—sugar cones, waffle cones, and rolled cones.

- Durability: Made from stainless steel and high-grade components, these machines offer long-term performance.

Who Needs Commercial Suppliers?

- Ice cream production factories

- Food processing plants

- Frozen dessert brands

- Exporters of cone products

- Franchise dessert chains

Choosing a reputable supplier ensures your business gets reliable after-sales support, spare parts, and customization options.

Automatic Ice Cream Cone Baking Machine Makers

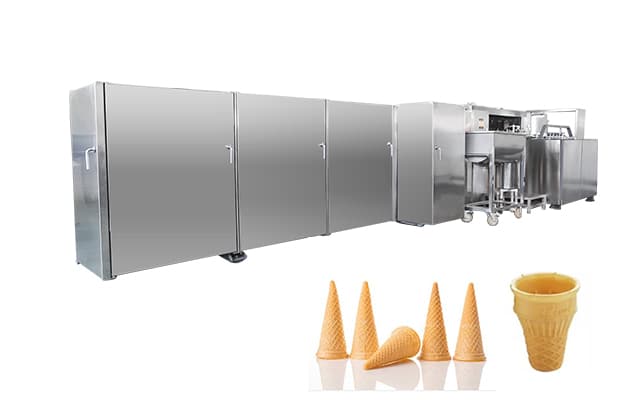

The backbone of modern cone production lies in automatic ice cream cone baking machines. These are designed to bake cone batter into perfectly shaped edible containers in a fast and consistent manner.

Why Go Automatic?

- Efficiency: Automation eliminates the need for manual pouring and shaping.

- Uniformity: Ensures all cones are baked to the same consistency and color.

- Safety: Reduces the need for human contact with hot plates or moving parts.

- Speed: High-speed rotary baking systems can deliver up to 6000 cones/hour depending on size and settings.

Technologies Used

- PLC (Programmable Logic Controller)

- Touchscreen operation panels

- Adjustable temperature and time controls

- Servo-driven mold movements

- Infrared or electric heating

These machines come with customization options for different cone types and batter formulas.

Waffle Cone Maker Equipment Manufacturers

Waffle cones are one of the most popular cone varieties worldwide. Their distinct texture and sweet crunch add value to any scoop of ice cream. That’s why specialized waffle cone maker equipment manufacturers are in demand.

Key Considerations in Waffle Cone Equipment

- Heating Plate Materials: Cast iron, non-stick coating, or Teflon

- Adjustable Cone Size: Machines allow for changes in length and diameter

- Rolling Mechanism: Includes cone rolling arms or drum rollers

- Voltage & Power: Designed for regional power requirements (110V, 220V, 380V)

- Production Lines: From single-head to 60-head lines

Many manufacturers also offer semi-automatic and fully automatic options depending on budget and volume needs.

Industrial Sugar Cone Machine Manufacturers

Sugar cones are thinner and crispier than waffle cones, with a more uniform appearance. Industrial sugar cone machine manufacturers cater to businesses that need consistent, large-scale cone production for retail packaging.

Specifications of Sugar Cone Machines

- Baking Speed: Adjustable cycles (e.g., 1.5 to 2 minutes)

- Row Count: Machines with 12, 24, 36, 60, or 72 molds

- Output Capacity: Ranges from 3,000 to 9,000 cones/hour

- Cooling & Stacking: Built-in conveyors, coolers, and cone stackers

- Quality Materials: SUS304 stainless steel body

Manufacturers like DT Food Machine, professional ice cream cone machine manufacturers design these systems for export, ensuring they meet CE, ISO, and food safety certifications.

Cone Rolling Machine Suppliers

Cone rolling machines are specialized equipment that roll baked wafers into cone shapes using mechanical or pneumatic rollers. These are often part of a full production line.

Why Cone Rolling Is Important

Evenly rolled cones affect both aesthetics and usability. A poorly rolled cone may leak or break under ice cream weight.

Manual vs. Automatic Rollers

- Manual Rollers: Low investment, suited for small bakeries.

- Automatic Rollers: High speed, consistent shapes, lower labor costs.

Most high-end cone lines today integrate cone rolling, trimming, and stacking in one flow.

Edible Ice Cream Cone Production Line Manufacturers

An edible ice cream cone production line is a full setup that includes batter mixing, baking, rolling, cooling, and stacking units. Leading manufacturers offer turnkey solutions for businesses aiming to automate their entire cone production.

Components of a Full Production Line

- Batter Mixer: Blends flour, sugar, and other ingredients.

- Feeder System: Pumps the batter into baking plates.

- Rotary Baking Oven: Bakes wafer sheets in circular motion.

- Cone Roller: Rolls wafers into cones.

- Cooling Conveyor: Prepares cones for packaging.

- Stacking & Counting Unit: Organizes cones in batches.

Such production lines can be customized for different cone styles, including:

- Mini cones

- Jumbo cones

- Double cones

- Flat-bottom cones

- Heart-shaped cones

Customized Ice Cream Cone Equipment Suppliers

Different markets demand different cone styles. That’s why customized ice cream cone equipment suppliers are so valuable.

Why Customization Matters

- Regional Preferences: Some markets prefer flat-bottom cones, others love rolled sugar cones.

- Brand Identity: Cone shape can be a branding element for premium ice cream brands.

- Machine Footprint: Equipment must fit existing factory layout.

- Voltage & Certifications: Adapts to the buyer’s country regulations.

Leading manufacturers provide services like:

- OEM/ODM manufacturing

- Cone design consultation

- Test runs with buyer’s ingredients

- Remote troubleshooting and training

Ice Cream Cone Making Machine Exporters

With the global growth of the dessert industry, ice cream cone making machine exporters are expanding to serve international clients. These exporters must balance technical innovation, global compliance, and efficient logistics.

What Makes a Good Exporter?

- Multilingual Support

- Clear Documentation (User Manual, Installation Guide)

- International Certifications (CE, ISO, SGS)

- Packaging for Overseas Transport

- Online and On-Site Support

Top exporters also offer spare parts, installation videos, and 24/7 technical assistance for international buyers.

Where to Buy Ice Cream Cone Machines?

Finding the right cone machine involves more than just price comparison. Here’s where you can source high-quality machines:

- Manufacturer Websites: Buy directly from the factory (e.g., DT Food Machine)

- Trade Platforms

- Food Machinery Exhibitions: Gulfood, Anuga, SIAL, etc.

- Industry Referrals: Ask other ice cream producers

- Local Agents: Sometimes represent foreign brands with local support

Always check for factory tour options, sample cone runs, and customer testimonials.

How to Choose the Best Ice Cream Cone Machine Manufacturer?

When choosing an ice cream cone machine manufacturer, consider the following checklist:

| Criteria | Importance |

|---|---|

| Years of experience | High |

| International certifications | High |

| Range of machine types | Medium |

| Customization availability | High |

| After-sales service | Very High |

| Reference projects | Medium |

| Price-performance ratio | High |

| Export history | High |

Request a sample test, technical specifications, and a quotation before making a decision.

Common Cone Types Manufacturers Offer

Manufacturers can produce machines for a wide range of edible cone styles:

- Waffle Cones – Sweet, crunchy, grid-pattern cones

- Sugar Cones – Thin, crisp, brown cones with a uniform look

- Cake Cones – Soft, dry, light-colored flat-bottom cones

- Rolled Cones – Rolled tubes with open tops

- Heart-shaped Cones – Romantic novelty cones

- Double or Twin Cones – For serving two scoops at once

Make sure the manufacturer has the molds and experience for your preferred cone style.

DT Food Machine – Trusted Ice Cream Cone Machine Manufacturer and Supplier

If you’re searching for a reliable and experienced ice cream cone machine manufacturers, look no further than DT Food Machine.

Why Choose DT Food Machine?

- Over 15 Years of Experience: We’ve been manufacturing cone-making machines for over a decade, trusted by clients in 30+ countries.

- Complete Product Line: From single-head manual cone makers to fully automatic 60-head production lines.

- Global Reach: We export our machines worldwide with CE, ISO, and food-grade certifications.

- Customization Experts: We tailor cone sizes, shapes, and machine voltage to your needs.

- Outstanding After-Sales Service: DT offers online installation guidance, maintenance videos, and 24/7 technical support.

- Competitive Pricing: Get factory-direct prices without compromising on quality.

Our Product Range

- Automatic Waffle Cone Machines

- Sugar Cone Production Lines

- Rotary Baking Systems

- Cone Rolling Machines

- Batter Mixers and Feeder Pumps

- Customized Cone Molds

Whether you’re a startup or a large-scale food processing company, DT Food Machine is your one-stop solution for ice cream cone production equipment.

Contact us today for a free consultation, technical quote, or sample video demonstration. DT Food Machine is here to bring your ice cream business to the next level.