Introduction: Growing Demand for Waffle Cone Making Machines in the USA

The United States of America is one of the world’s largest consumers of ice cream and frozen desserts. From national ice cream chains and amusement parks to local artisanal gelato shops and food trucks, waffle cones remain a core product with stable and growing demand. As a result, the Waffle Cone Making Machine to the United States of America has become a high-value category in food processing equipment imports.

In recent years, American buyers have increasingly shifted from manual or semi-automatic cone production to automatic waffle cone making machines, aiming to improve consistency, hygiene, labor efficiency, and output capacity. This trend has opened strong opportunities for professional manufacturers and exporters of waffle cone production equipment.

We, DT Food Machine Co.Ltd. provides a comprehensive overview of exporting, selecting, and operating a waffle cone making machine for the U.S. market, helping importers, distributors, and factory owners make informed decisions.

Overview of the Waffle Cone Market in the United States

Ice Cream Consumption and Cone Demand

The U.S. ice cream industry generates billions of dollars annually. Waffle cones, compared with paper or sugar cones, are perceived as premium products due to their taste, texture, and visual appeal. This preference directly drives demand for:

- Commercial waffle cone machines

- Industrial waffle cone production lines

- Automatic waffle cone baking machines

Large-scale ice cream manufacturers and regional cone suppliers require stable, continuous cone production, making industrial equipment essential.

Why the United States Imports Waffle Cone Making Machines

Although the U.S. has domestic equipment suppliers, many buyers choose to import waffle cone making machines due to:

- Competitive pricing

- Mature manufacturing technology

- Customizable configurations

- Faster ROI for small and medium factories

The Waffle Cone Making Machine to the United States of America is therefore a well-established import category.

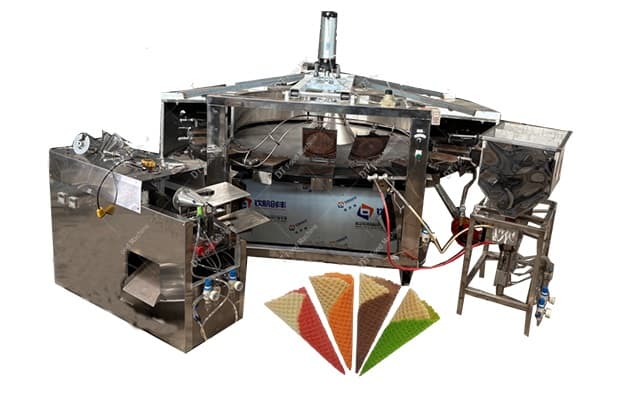

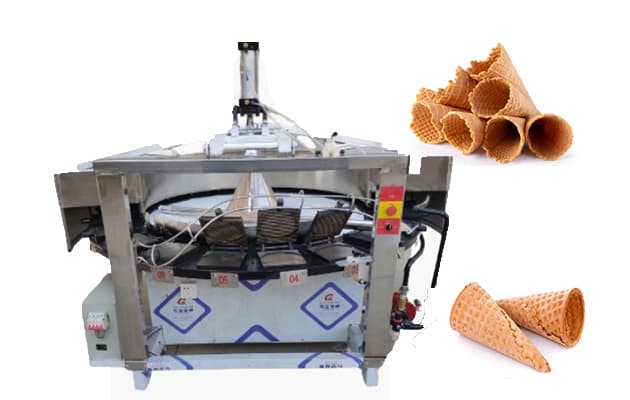

What Is a Waffle Cone Making Machine?

A waffle cone making machine is a specialized food processing machine designed to produce waffle-style ice cream cones. The machine automates or semi-automates the process of batter baking, cone forming, cooling, and stacking.

Core Functions

- Batter dosing and spreading

- High-temperature baking plates

- Cone rolling or molding

- Automatic demolding

- Cooling and shaping

Depending on the model, machines may be manual, semi-automatic, or fully automatic.

Types of Waffle Cone Making Machines for the U.S. Market

Manual Waffle Cone Machines

Manual machines are suitable for small shops, startups, or test production.

Features:

- Low investment cost

- Simple operation

- Small footprint

Limitations:

- Low production capacity

- Labor-intensive

- Inconsistent quality

Manual machines are rarely used for export-scale operations but may be imported by niche businesses.

Semi-Automatic Waffle Cone Making Machines

Semi-automatic machines are widely used by small and medium manufacturers in the U.S.

Advantages:

- Balanced cost and efficiency

- Stable cone quality

- Moderate labor requirement

These machines are popular in local cone factories and food service suppliers.

Fully Automatic Waffle Cone Making Machines

Fully automatic models dominate large-scale waffle cone making machine to the United States of America imports.

Key benefits:

- High production capacity

- Consistent cone size and texture

- Reduced labor costs

- Continuous operation

These machines are suitable for industrial ice cream cone manufacturers supplying nationwide distribution.

Key Technical Components of a Waffle Cone Making Machine

Baking Plates

High-quality baking plates are typically made of cast iron or aluminum alloy with food-grade non-stick coating. Uniform heat distribution is essential for consistent cone color and texture.

Heating System

U.S. buyers typically choose between:

- Electric heating (common in the USA)

- Gas heating (natural gas or LPG)

Electric heating is often preferred due to easier compliance with local safety regulations.

Cone Rolling System

Modern machines use automatic cone rollers with adjustable angles, allowing different cone sizes for:

- Ice cream cones

- Gelato cones

- Specialty waffle cones

Control System

Advanced waffle cone machines exported to the USA usually include:

- PLC control panels

- Touch screen interfaces

- Temperature and time control

This ensures operational stability and ease of training.

Production Capacity and Output Options

When selecting a waffle cone making machine to the United States of America, production capacity is a decisive factor.

Typical capacity ranges include:

- 800–1,200 cones per hour (semi-automatic)

- 2,000–4,000 cones per hour (automatic)

- 5,000+ cones per hour (industrial production line)

Buyers should match capacity with current demand and future expansion plans.

Compliance with U.S. Food Safety Standards

FDA Compliance

Machines exported to the USA must comply with FDA food contact material requirements. This includes:

- Food-grade stainless steel

- Non-toxic coatings

- Hygienic design

Electrical Standards

U.S. voltage and standards usually require:

- 208V / 220V / 480V

- 60Hz frequency

- UL-compliant electrical components (preferred)

Professional exporters customize machines specifically for the U.S. electrical system.

Packaging and Shipping of Waffle Cone Making Machines to the USA

Export Packaging

Machines are typically packed in:

- Fumigation-free wooden crates

- Anti-rust protective film

- Shock-resistant internal supports

Shipping Methods

- Sea freight (most common for large machines)

- LCL or FCL containers

- Port delivery or door-to-door options

Reliable exporters provide full documentation including commercial invoice, packing list, and bill of lading.

Installation and After-Sales Support in the United States

A critical consideration for American buyers is technical support.

Installation Options

- On-site engineer installation

- Remote video guidance

- Detailed English manuals

Spare Parts Availability

High-quality waffle cone machine suppliers provide:

- Long-term spare parts supply

- Wear-part lists

- Fast international shipping

Cost Analysis: Waffle Cone Making Machine to the United States of America

Price Influencing Factors

- Automation level

- Production capacity

- Heating method

- Customization requirements

Typical price ranges:

- Manual machine: USD 2,000–5,000

- Semi-automatic: USD 8,000–20,000

- Fully automatic line: USD 30,000–100,000+

While the initial investment may vary, automatic machines offer superior long-term profitability.

ROI and Business Profitability

For U.S. cone manufacturers, investing in a waffle cone making machine offers:

- Lower labor cost per unit

- Higher daily output

- Improved product consistency

- Faster payback period

Many buyers report ROI within 6–18 months depending on production volume.

Customization for the U.S. Market

Professional exporters adapt machines for American buyers by offering:

- Custom cone sizes

- Logo-embossed baking plates

- Energy-efficient designs

- Multi-language interfaces

Customization increases brand differentiation in the competitive U.S. market.

Why Choose an Experienced Export Manufacturer

Selecting the right supplier is critical for importing a waffle cone making machine to the United States of America.

Key evaluation criteria include:

- Export experience to North America

- Understanding of U.S. regulations

- Proven machine performance

- Strong after-sales service

An experienced manufacturer minimizes risks related to customs clearance, compliance, and operational issues.

Waffle Cone Making Machine Manufacturer-DT Food Machine

The Waffle Cone Making Machine to the United States of America represents a stable and profitable investment opportunity driven by strong consumer demand for premium ice cream products. With the right equipment, American manufacturers can significantly improve efficiency, product quality, and competitiveness.

By selecting a machine that meets U.S. food safety standards, matches production requirements, and is supported by reliable after-sales service, importers can achieve long-term success in the waffle cone industry.

For businesses seeking scalable growth in the U.S. ice cream market, investing in a professional waffle cone making machine is not just a purchase—it is a strategic decision.