1. Introduction to Spaghetti Packaging Machines

In the fast-growing pasta industry, efficiency and precision define profitability. A spaghetti packaging machine is a vital part of any modern pasta production line, designed to automate the weighing, filling, sealing, and bagging process for long-cut pasta such as spaghetti, linguine, and vermicelli.

For pasta manufacturers, the right spaghetti packaging equipment not only improves productivity but also ensures product hygiene, accurate weight control, and attractive retail presentation. From small-scale workshops to industrial pasta factories, an automatic spaghetti packaging machine can greatly reduce manual labor and operational costs.

2. What is a Spaghetti Packaging Machine?

A spaghetti packaging machine is a specialized automatic system that handles long pasta products. The process typically includes:

- Weighing: Accurately measuring the pasta portions.

- Bundling: Aligning spaghetti strands into neat bundles.

- Wrapping or bag forming: Creating the film bag or using pre-made pouches.

- Filling and sealing: Filling the package and sealing it for freshness.

- Labeling and cutting: Printing expiration dates or batch numbers, cutting to length.

Modern machines integrate advanced sensors, servo motors, and PLC control systems to ensure stable operation and high-speed performance. Some are part of a complete spaghetti packaging line, connecting seamlessly to upstream drying and cooling units and downstream carton packing systems.

3. Why Invest in an Automatic Spaghetti Packaging Machine?

3.1 Efficiency and Productivity

Manual packaging is time-consuming and inconsistent. With an automatic spaghetti packing machine, operators can package hundreds of kilograms per hour. Advanced models achieve up to 30–60 packs per minute, depending on product length and packaging material.

3.2 Accuracy and Waste Reduction

Equipped with intelligent weighing systems, the machine ensures every package meets the exact weight requirement—typically 250 g, 500 g, or 1 kg—minimizing overfill or product waste.

3.3 Hygiene and Food Safety

Made from AISI 304 or 316 stainless steel, spaghetti packaging equipment complies with international food safety standards (HACCP, CE, FDA). Fully enclosed designs protect pasta from contamination.

3.4 Flexibility for Different Packaging Types

Whether you package long-cut spaghetti in pillow bags, shrink-wrapped bundles, or cartons, the machine can be adjusted for various formats and packaging materials such as polypropylene (PP), polyethylene (PE), or composite film rolls.

3.5 Cost Savings

While the initial investment may seem high, automation drastically lowers labor costs and reduces human error. Over time, the return on investment (ROI) is significant for high-volume producers.

4. Main Components and Working Principle

A high-quality spaghetti weighing and sealing machine generally includes the following modules:

| Component | Function |

|---|---|

| Feeding Conveyor | Transports spaghetti from the drying line to the packaging area. |

| Vibrating Aligning Device | Aligns spaghetti strands evenly before bundling. |

| Weighing Unit | Measures accurate bundle weight using sensors or load cells. |

| Film Unwinding System | Feeds packaging film into the forming tube. |

| Bag Forming Unit | Shapes the film into a tube and seals one end to form a bag. |

| Filling Section | Inserts spaghetti bundles into the formed bag. |

| Sealing & Cutting Unit | Heat seals the top of the bag and cuts it to length. |

| Coding & Labeling Device | Prints date codes or labels. |

| Output Conveyor | Transfers finished bags to the next process (carton packing). |

Most automatic spaghetti bagging machines use PLC + touchscreen (HMI) interfaces, allowing operators to adjust parameters like speed, bag length, sealing temperature, and bundle weight with ease.

5. Technical Specifications (Example)

Below is a sample specification table for an industrial spaghetti packaging line:

| Parameter | Specification |

|---|---|

| Model | DT-SP600 |

| Product Type | Long pasta (Spaghetti, Linguine, Vermicelli) |

| Package Weight | 250 g – 1000 g |

| Bag Length | 200 mm – 500 mm |

| Packaging Speed | 30–60 packs/min |

| Film Material | OPP/CPP, PET/PE, BOPP/CPP, etc. |

| Power Supply | 380 V / 50 Hz / 3 Phase |

| Total Power | 4.5 kW |

| Machine Dimension | 3800 mm × 1200 mm × 2000 mm |

| Machine Weight | 850 kg |

| Material | SUS 304 Stainless Steel |

| Control System | PLC + Touchscreen |

| Air Pressure | 0.6 MPa |

These parameters can be customized based on production capacity and packaging format.

6. Long-Tail Keywords and Applications

A spaghetti packaging machine is part of a broader family of pasta packaging systems, which also includes:

- Automatic pasta weighing and filling machine

- Long-cut pasta bagging equipment

- Industrial spaghetti bundling machine

- Flow wrap packaging machine for spaghetti

- Spaghetti film sealing and cutting machine

- High-speed pasta packaging system

- Automatic spaghetti wrapping machine

- Spaghetti pouch sealing machine

These machines are widely used in industrial pasta factories, food packaging companies, and contract manufacturing plants.

They can also handle similar products such as linguine, fettuccine, vermicelli, and rice noodles with minimal adjustment.

7. Customization Options

When choosing a spaghetti packaging line, manufacturers often request tailored configurations. Some available customizations include:

- Bundle length & diameter adjustment: 200–500 mm spaghetti length options.

- Film type compatibility: Laminated film, shrink film, recyclable packaging materials.

- Multi-weight packaging: 250 g retail packs or 5 kg catering bags.

- Integrated labeling & barcode printing.

- End-of-line palletizing systems for large factories.

- Automatic changeover systems for quick product type switching.

DT Food Machine, for example, offers complete custom spaghetti packaging solutions integrating weighing, filling, bagging, and labeling—all in one line.

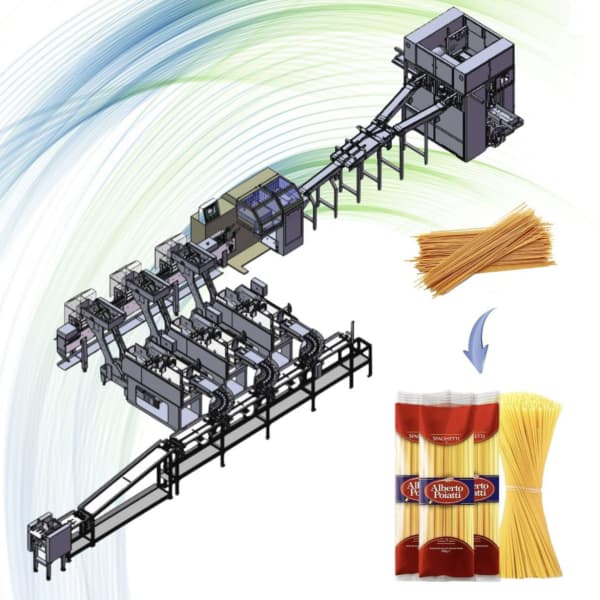

8. Integration with Pasta Production Line

A spaghetti packaging machine typically connects downstream of a pasta drying and cooling unit. The integrated workflow may look like this:

- Extrusion: Pasta dough is extruded into long strands.

- Cutting & Drying: The strands are cut to standard spaghetti length and dried.

- Cooling & Alignment: Dried spaghetti is cooled and arranged into bundles.

- Automatic Feeding: Bundles are transferred automatically to the packaging line.

- Weighing & Bagging: The spaghetti is weighed and packed into bags.

- Sealing & Labeling: Bags are sealed and labeled with production details.

- Cartoning & Palletizing: Finished packs are placed into cartons for shipment.

This seamless integration ensures continuous, hygienic, and efficient production—critical for maintaining pasta quality and shelf life.

9. How to Choose the Right Spaghetti Packaging Equipment

Selecting the best spaghetti packaging machine depends on your production needs. Consider the following factors:

9.1 Production Volume

If you package small batches, a semi-automatic model might suffice. For industrial production, choose a fully automatic high-speed spaghetti packaging line.

9.2 Packaging Type

Do you prefer pillow bags, shrink-wrapped bundles, or cardboard boxes? Each format requires specific machinery.

9.3 Space and Layout

Check your factory layout. Machines for long-cut pasta require enough space for conveyors and bundle alignment systems.

9.4 Technical Support

Choose a supplier offering installation, operator training, and after-sales support. Brands like DT Food Machine provide global technical service and spare parts availability.

9.5 Budget and ROI

While machine costs vary (from USD 15,000 to 60,000+ depending on configuration), automation quickly pays off in labor savings and efficiency.

10. Maintenance and Safety Tips

Maintaining your spaghetti bagging equipment ensures longevity and food safety:

- Regularly clean sealing jaws and conveyors to prevent contamination.

- Inspect sensors and load cells for accurate weighing.

- Replace worn belts or sealing elements promptly.

- Check the film tension and alignment frequently.

- Follow safety procedures: emergency stops, interlock guards, and operator training.

A preventive maintenance schedule can extend machine life beyond 10 years with consistent performance.

11. Why Choose DT Food Machine as Your Spaghetti Packaging Partner

DT Food Machine specializes in customized pasta processing and packaging solutions for clients worldwide. With over a decade of experience, DT provides:

- Turnkey spaghetti production and packaging lines

- CE and ISO-certified equipment

- Tailored configurations for different pasta shapes and capacities

- Installation and after-sales service across Asia, Europe, and Latin America

- Energy-efficient, high-speed, and durable designs

By partnering with DT Food Machine, you gain not only reliable machinery but also a professional technical team to guide installation, training, and continuous improvement.

12. Request a Quotation (RFQ)

If you’re planning to upgrade your packaging line or build a new pasta factory, contact DT Food Machine for a custom quotation.

Please include:

- Type of pasta (e.g., spaghetti, linguine, fettuccine)

- Packaging weight and format

- Target capacity (packs/hour or kg/day)

- Preferred packaging material (film, bag, box)

- Voltage and factory layout information

Email: info@dtfoodmachine.com

Website: www.dtfoodmachine.com

13. Spaghetti Packaging Machine

The pasta industry is evolving rapidly, and automation is no longer optional—it’s essential. A spaghetti packaging machine streamlines operations, enhances product quality, and increases profitability.

From automatic spaghetti weighing and sealing machines to complete pasta packaging systems, modern technology allows you to produce consistent, attractive, and safe pasta packs that meet international market standards.

With innovative solutions from DT Food Machine, you can elevate your spaghetti production line to the next level—efficient, precise, and built for long-term success.