1. Введение

The bubble washing machine vegetable and fruit is an advanced piece of equipment designed for cleaning fresh produce using a combination of water immersion и air bubble agitation. This cleaning method is gentle, эффективный, and environmentally friendly, making it suitable for both delicate and firm produce.

As global consumers increasingly demand ready-to-eat, pre-washed, and organic-certified produce, processors are upgrading from traditional manual washing to fully automated bubble washing systems.

1.1 Why Bubble Washing Matters in Modern Food Processing

- Соответствие безопасности пищевых продуктов

Regulatory agencies such as the FDA, EU Commission, and CFIA require food producers to minimize microbial contamination, pesticide residues, and physical debris. - Product Quality Preservation

Bubble washing prevents bruising, discoloration, and nutrient loss, especially important for export markets. - Операционная эффективность

Handles high volumes — from 500 kg/h for small plants к 10,000+ kg/h for large industrial facilities.

2. How a Bubble Washing Machine Works

А bubble washing machine vegetable and fruit uses air bubbles generated by a blower to gently agitate produce in water, loosening dirt and contaminants.

2.1 The Process Flow

- Loading

Produce enters via a conveyor or manual hopper. - Water Tank Immersion

Fruits and vegetables are fully submerged. - Bubble Injection

Compressed air enters through perforated pipes, creating turbulence. - Dirt Separation

Heavy particles settle, light debris floats away. - Final Rinse

Clean water sprays remove any residual contaminants. - Увольнять

A conveyor transfers produce to the next processing stage.

2.2 Key Science Behind Bubble Cleaning

- Hydrodynamic Effect: Bubbles create micro-currents that penetrate leaf folds.

- Surface Tension Reduction: Air bubbles reduce adhesion between dirt and produce skin.

- Oxygen Enrichment: Helps maintain freshness during cleaning.

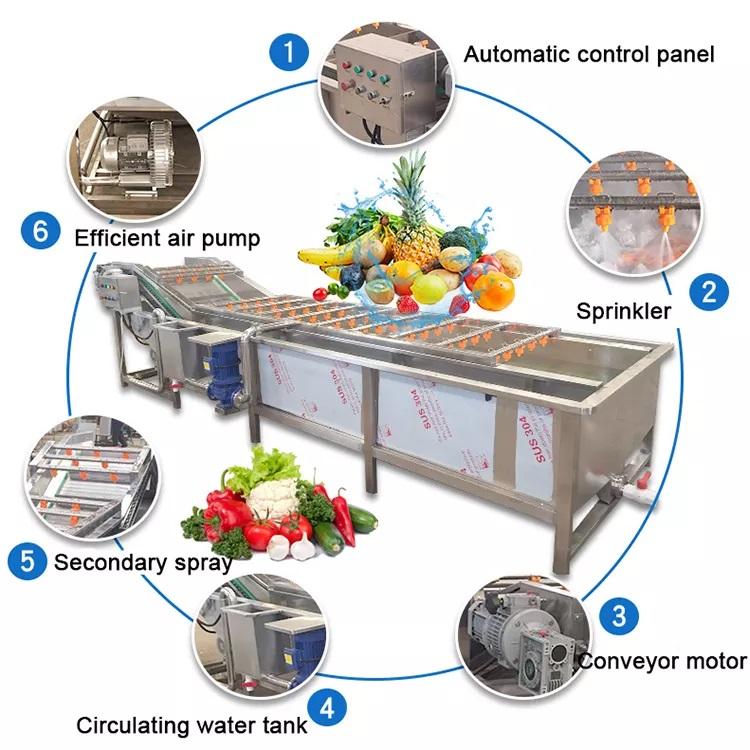

3. Machine Design & Компоненты

The bubble washing machine vegetable and fruit is engineered for долговечность, гигиена, и легкая очистка.

| Компонент | Функция |

|---|---|

| Water Tank | Holds the washing solution. |

| Воздуходувка | Generates air for bubble production. |

| Mesh Conveyor | Moves produce through the cleaning zone. |

| Sediment Trap | Collects heavy debris. |

| Overflow Outlet | Removes floating impurities. |

| Rinse Section | Provides final clean water spray. |

| Панель управления | Manages speed, air flow, and water circulation. |

Материал: SUS304 нержавеющая сталь (стандартный), SUS316 for highly acidic produce.

4. Таблица технических параметров

| Модель | Емкость (кг/ч) | Власть (кВт) | Water Volume (Л) | Размеры (мм) | Масса (кг) | Материал |

|---|---|---|---|---|---|---|

| ДТ-500 | 500 | 2.2 | 400 | 3000×1000×1300 | 280 | SUS304 |

| ДТ-1000 | 1000 | 3.7 | 600 | 4000×1200×1300 | 380 | SUS304 |

| ДТ-2000 | 2000 | 5.5 | 900 | 5000×1400×1350 | 520 | SUS304 |

| DT-3000 | 3000 | 7.5 | 1200 | 6000×1500×1400 | 650 | SUS304 |

| DT-5000 | 5000 | 11 | 1500 | 8000×1600×1450 | 950 | SUS304 |

5. Product Applications

- Leafy Greens: Латук, шпинат, kale, капуста.

- Root Vegetables: Морковь, картофель, radishes, beets.

- Fruits: Strawberries, grapes, яблоки, citrus.

- Травы: Mint, базилик, coriander.

- Medicinal Plants: Ginseng, chrysanthemum.

6. Benefits Over Other Washing Methods

| Особенность | Bubble Washing Machine | Spray Washing | Manual Washing |

|---|---|---|---|

| Damage to Produce | Very Low | Середина | Переменная |

| Cleaning Thoroughness | Высокий | Середина | Низкий |

| Трудовое требование | Низкий | Середина | Высокий |

| Water Use Efficiency | Высокий | Середина | Низкий |

7. Installation Guide

- Select Location – Level floor, near water & drainage.

- Install Utilities – Connect 3-phase power, water inlets, and drainage.

- Assembly – Attach blower, конвейер, and rinse sections.

- Testing – Run with water only to check for leaks.

8. Operation Tips

- Pre-rinse heavily soiled produce before loading.

- Adjust bubble intensity for delicate items.

- Keep water temperature low to maintain freshness.

9. Maintenance Schedule

| Частота | Action |

|---|---|

| Ежедневно | Drain & clean tank, rinse filters. |

| Еженедельно | Inspect blower and pump. |

| Ежемесячно | Remove scaling, sanitize tank. |

| Ежегодно | Заменить уплотнения, bearings. |

10. Вода & Energy Saving Features

- Recirculation system reuses up to 80% of water.

- Automatic debris removal extends water life.

- Variable blower speed reduces power use.

11. Тематические исследования

Случай 1 – Leafy Green Processor in California

- Емкость: 3000 кг/ч

- Результат: Reduced labor by 70%, water use by 40%.

- Рентабельность: Achieved in 14 месяцы.

Случай 2 – Berry Exporter in Chile

- Емкость: 2000 кг/ч

- Результат: Reduced bruising damage from 6% to under 1%.

12. Рыночные тенденции

- Растущий спрос на organic-certified washed produce.

- Increasing adoption in Азиатско-Тихоокеанский регион due to export markets.

- Интеграция с optical sorting machines.

13. Как выбрать правильную машину

- Capacity Requirements

- Тип продукта

- Доступность пространства

- Budget and ROI Goals

- Послепродажная поддержка

14. Price Ranges

- Маленький (500–1000 кг/ч): $2,500–5000 долларов США

- Середина (2000–3000 кг/ч): $6,000–$10,000

- Большой (5000+ кг/ч): $12,000- 20 000 долларов+

15. Extended FAQs

Q.: Can it be used for seafood?

А: Да, with proper corrosion protection.

Q.: Can it connect to peeling machines?

А: Да, commonly integrated in full processing lines.

Q.: Is ozone disinfection available?

А: Да, as an optional add-on.

16. Troubleshooting Guide

| Проблема | Возможная причина | Решение |

|---|---|---|

| Weak bubbles | Low blower pressure | Check blower filter |

| Poor cleaning | Overloaded tank | Reduce feed rate |

| Water overflow | Blocked drain | Clean outlet |

17. Заключение

А bubble washing machine vegetable and fruit is not just a cleaning device — it’s a производительность, качество, and safety investment. With the right model, you can increase throughput, улучшить гигиену, and reduce operational costs.