În industria alimentară în continuă evoluție, automatizarea joacă un rol crucial în satisfacerea cerințelor tot mai mari de igienă, consistență, si viteza. The mașină complet automată de făcut conuri de înghețată stă ca o mărturie a acestei revoluții tehnologice. Indiferent dacă conduceți o brutărie mică sau o unitate de producție alimentară la scară largă, adoptarea acestei mașini vă asigură că produceți conuri de înaltă calitate, cu forță de muncă minimă și eficiență maximă.

Aici, discutăm profund asupra caracteristicilor, aplicatii, Specificații tehnice, și beneficiile mașinii, acoperind, de asemenea, cuvintele cheie și sinonimele asociate cu coadă lungă pentru o mai bună înțelegere.

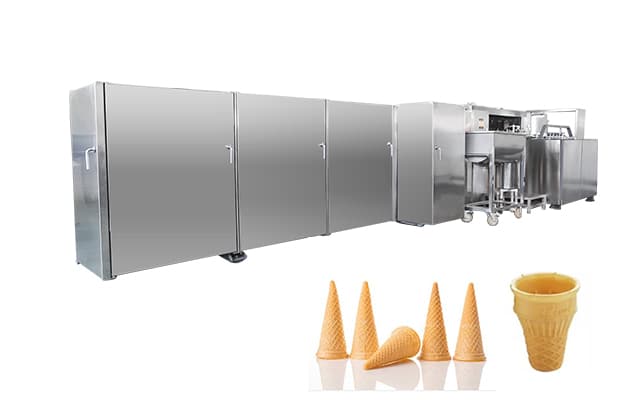

Linie automată de producție a cornetului de înghețată

The linie automată de producție a cornetului de înghețată este o soluție completă care automatizează fiecare pas de fabricare a conurilor - de la amestecarea aluatului, coacerea, rulare, până la stivuirea finală. Mărește semnificativ producția, menținând în același timp uniformitatea formei, dimensiune, și gust.

Componentele cheie ale liniei de producție:

- Sistem de amestecare a aluatului: Amestecă ingredientele într-o formă netedă, aluat consistent.

- Sistem de coacere: Utilizează plăci rotative de copt sau cuptoare tunel.

- Unitate de formare și laminare: Rulează automat foile coapte în conuri.

- Sistem de racire si stivuire: Răcește conurile și le stivuiește pentru ambalare.

Această soluție end-to-end permite producătorilor să crească producția, reducând în același timp dependența de munca manuală.

Mașină industrială pentru cornet de înghețată pentru un volum mare de ieșire

The mașină industrială pentru cornet de înghețată este proiectat pentru utilizare grea. Aceste mașini sunt construite cu corpuri robuste din oțel inoxidabil și au mai multe forme de coacere (din 12 la 60+ farfurii) pentru a satisface cerințele de producție variate.

Caracteristici:

- Potrivit pentru producerea conurilor de zahăr, conuri de waffle, și conuri crocante.

- Sistem de control PLC pentru operare și monitorizare ușoară.

- Control variabil de temperatură și viteză.

- Preîncălzire și coacere rapidă (la fel de jos ca 1.5 minute pe ciclu).

- Opțiune de a personaliza dimensiunea conului, grosime, și textură.

Designul industrial asigură durabilitate, igienă, și respectarea standardelor de siguranță alimentară.

Aparat electric de conuri de inghetata pentru eficienta energetica

În timp ce mașinile tradiționale se bazau adesea pe încălzirea pe bază de gaz, cel aparat electric de conuri de inghetata ofera un curatator, mai sigur, și opțiune mai eficientă din punct de vedere energetic. Aceste mașini sunt ideale pentru mediile în care utilizarea gazului este limitată sau nedorită.

Avantajele modelelor electrice:

- Control precis al temperaturii prin termostate digitale.

- Emisii reduse și niveluri de zgomot.

- Mai ușor de instalat și întreținut în comparație cu modelele pe gaz.

- Se potrivește mai bine pentru configurații interioare și închise.

Producătorii de conuri electrice sunt perfecte pentru producătorii conștienți de mediu care urmăresc producția durabilă.

Mașină de făcut conuri de vafe: Conuri crocante și personalizabile

Folosit adesea interschimbabil cu conurile obișnuite, conuri de waffle au o textura si un gust distinct. The mașină de făcut conuri de vafe se adresează în mod specific acestei nișe, permițând întreprinderilor să ofere opțiuni de conuri premium.

Opțiuni de personalizare a conului de vafe:

- Lungimea conului: 90mm–160 mm

- Diametrul de sus: 30mm–70mm

- Grosime: 1mm–3mm

- Model: Fagure sau spirală

Conurile de vafe atrag brandurile gourmet și magazinele de înghețată artizanală care doresc să-și diferențieze ofertele.

Mașină de coacere cu conuri de zahăr: Pentru iubitorii de conuri clasice

The mașină de copt cu conuri de zahăr este construit pentru a crea dulceața clasică, conuri crocante găsite în majoritatea setărilor comerciale. Aceste conuri sunt făcute cu un aluat dulce care este copt uniform într-un crocant, textura aurie.

Caracteristici:

- Distribuție uniformă a căldurii pe plitele de copt.

- Timp de coacere rapid (8-15 secunde pe con).

- Ejecție complet automată a conului.

- Deșeuri minime datorită dispersării uniforme a aluatului.

Conurile de zahăr continuă să domine piața globală a cornetelor de înghețată, făcând această mașină un element de bază în industrie.

Tabelul de specificații tehnice: Mașină complet automată pentru cornet de înghețată

Mai jos este un grafic cu specificații generale pentru un model popular de mașină complet automată pentru cornet de înghețată. Rețineți că specificațiile pot varia în funcție de model și producător.

| Specificații | Detalii |

|---|---|

| Numărul de model | DT-ICCM36 |

| Capacitatea de producție | 3000–6000 conuri/oră |

| Numărul de plăci de copt | 36 / 40 / 60 (personalizabil) |

| Lungimea conului | 90mm – 160 mm |

| Diametrul conului | 20mm – 60 mm |

| Timp de coacere pe ciclu | 1.5 - 2 minute |

| Sursa de alimentare | Electric / Gaz |

| Voltaj | 220V / 380V, 50Hz / 60Hz |

| Consum total de energie | 12 kw - 24 kW |

| Material | Oţel inoxidabil (Clasa alimentara 304) |

| Sistem de control PLC | Da (Panou HMI cu ecran tactil) |

| Dimensiuni | 3200mm x 1600mm x 2200mm |

| Greutate netă | Aproximativ. 2500 kg |

| Sistem de racire | Ventilatoare opționale răcite cu aer |

| Nivel de zgomot | ≤ 65 dB |

| Certificări | CE / ISO9001 / SGS |

Acest aspect tehnic îi ajută pe ingineri, cumpărători, și echipele de întreținere pentru a evalua adaptarea mașinii la nivelul lor de producție.

Mașină automată de formare a cornetului de înghețată: Forma perfectă de fiecare dată

The unitate de formare a conurilor în aceste mașini se asigură că fiecare con are forma perfectă de spirală. Mecanismele automate de formare previn spargerea, spori productivitatea, și permite un produs consistent.

Beneficii:

- Matrite personalizabile in forma de con (ascuţit, plat, curbat).

- Manipulare umană minimă - producție igienă.

- Brațele de rulare inteligente se adaptează la diferite materiale de conuri.

Acest lucru este deosebit de important pentru companiile care vând conuri de marcă care necesită o estetică consistentă.

Mașină de rulat conuri de înghețată de mare viteză

The unitate de rulare conică de mare viteză joacă un rol crucial în transformarea foilor plate coapte în forma emblematică de con. Viteza și precizia sunt primordiale în operațiunile cu randament ridicat.

Viteză & Caracteristici de eficiență:

- Poate rula 60-100 de conuri pe minut.

- Aliniere de precizie pentru a minimiza risipa de con.

- Compatibil cu stivuitoare de brațe robotizate pentru stivuire.

Mașinile echipate cu module de rulare de mare viteză pot tripla producția cu costuri mai mici cu forța de muncă.

Echipamente comerciale pentru conuri de înghețată pentru producție la scară largă

La operaţiile de scalare, echipamente comerciale pentru cornet de înghețată devine esentiala. Aceste mașini sunt destinate integrării în liniile de producție cu alte mașini de prelucrare a alimentelor, cum ar fi sistemele de ambalare și arome..

Capabilitati de integrare:

- Conectat cu benzi transportoare la stațiile de ambalare.

- Sisteme de coduri de bare și coduri QR pentru urmărirea loturilor.

- Sisteme de monitorizare în timp real a temperaturii, umiditate, și ieșire.

Astfel de integrări permit trasabilitatea deplină și eficiența în producția de alimente.

Mașină de fabricat conuri pentru uzul fabricii de alimente

Proiectat ținând cont de fabricile alimentare, aceste mașini oferă Conform GMP, usor de curatat, și operare automată caracteristici care reduc riscul și îmbunătățesc consistența rezultatelor.

Design pentru fabrici:

- Design de spălare cu forme de copt detașabile.

- Design modular pentru înlocuirea ușoară a pieselor.

- Sisteme de oprire de urgență și alarmă de defecțiuni.

Aceste mașini respectă reglementările stricte de siguranță alimentară, asigurarea fără riscuri, producție pe scară largă.

Avantajele utilizării mașinilor de fabricare a cornetului de înghețată complet automate

- Reducerea costului muncii: Intervenție umană minimă.

- Eficiență ridicată: Până la 6000 conuri/oră.

- Producție igienică: Îndeplinește standardele globale de siguranță alimentară.

- Personalizare: Dimensiunea conului, grosime, și modele.

- Interfață ușor de utilizat: HMI cu ecran tactil & comenzi PLC.

- Durabilitate: Construit din oțel inoxidabil rezistent la coroziune.

Aplicații în diferite sectoare

| Sector | Utilizare |

|---|---|

| Producători de înghețată | Producția în masă de conuri pentru înghețată ambalată sau cu cupă |

| Magazine de deserturi | Conuri personalizate sau premium în forme de vafe sau cornet de zahăr |

| Companii de export de alimente | Export în vrac de conuri cu conformitate internațională în materie de siguranță |

| Materiale pentru hoteluri și catering | Lanțul de aprovizionare al producției de conuri pentru hoteluri și evenimente |

| Lanțuri de franciză | Conuri de marcă uniformă în mai multe puncte de vânzare |

Sfaturi pentru alegerea mașinii potrivite pentru cornet de înghețată

- Varietate de conuri: Decideți dacă doriți vafe, zahăr, cu fundul plat, sau conuri ascuțite.

- Volumul de producție: Aliniați capacitatea cu producția dvs. zilnică sau orară.

- Sursa de energie: Alegeți între gaz și electric în funcție de configurația dvs.

- Nivel de automatizare: Automatizarea mai mare economisește forța de muncă și crește consistența.

- Serviciu & Garanție: Alegeți mașini cu garanție de 12-24 de luni și asistență locală de service.

Concluzie: Investește în viitorul producției de conuri

The mașină complet automată de făcut conuri de înghețată nu este doar un instrument – este o investiție strategică pentru companiile care își propun să conducă în calitate, eficienţă, și inovație. De la producție în loturi mici până la instalații la scară industrială, aceste mașini oferă performanțe de neegalat, precizie, și rentabilitate.

Dacă intenționați să vă simplificați producția de conuri, reduce costurile generale, și sporește calitatea produsului, adoptarea unei mașini de făcut cornet de înghețată complet automată este cea mai inteligentă mișcare înainte.