In the world of frozen desserts, presentation and flavor are everything. One of the most iconic elements of an ice cream experience is the conuri de waffle—crisp, golden, and freshly made. For businesses looking to boost their efficiency, attract more customers, și sporește calitatea produsului, investind într-o commercial waffle cone maker is a strategic move. This guide explores everything you need to know: tipuri, Caracteristici, cazuri de utilizare, buying advice, and even technical specifications.

Professional Ice Cream Cone Maker for Foodservice Industry

A professional ice cream cone maker is a high-output kitchen appliance designed to produce consistent, high-quality waffle cones. Unlike domestic models, commercial versions are built to withstand the rigors of daily, continuous operation in high-volume environments such as:

- Ice cream parlors

- Frozen yogurt shops

- Dessert cafes

- Camioane cu alimente

- Theme parks and fairs

- Hotel and resort buffets

The appeal of freshly made cones goes beyond aesthetics. The aroma, textură, and taste of freshly baked cones can dramatically increase customer satisfaction and even boost impulse purchases.

Heavy Duty Waffle Cone Machine for High-Volume Production

A heavy duty waffle cone machine is engineered to support long working hours and fast turnaround. Key features typically include:

- Fast heat-up time

- Non-stick cooking plates

- Digital or manual temperature controls

- Automatic timer with audible alert

- Cone-rolling tool or built-in roller

These machines are often made of stainless steel or cast iron, offering excellent durability and heat retention.

Benefits of Heavy-Duty Waffle Cone Machines:

| Caracteristică | Avantaj |

|---|---|

| Large cooking plates | Bigger cones or multiple small cones |

| Temperature precision | Consistent texture and browning |

| Fast output | Până la 120 conuri pe oră |

| Easy cleaning surfaces | Saves labor and reduces downtime |

| Dual plate options | Bake two cones at once |

Automatic Ice Cream Cone Making Machine: Labor-Saving Innovation

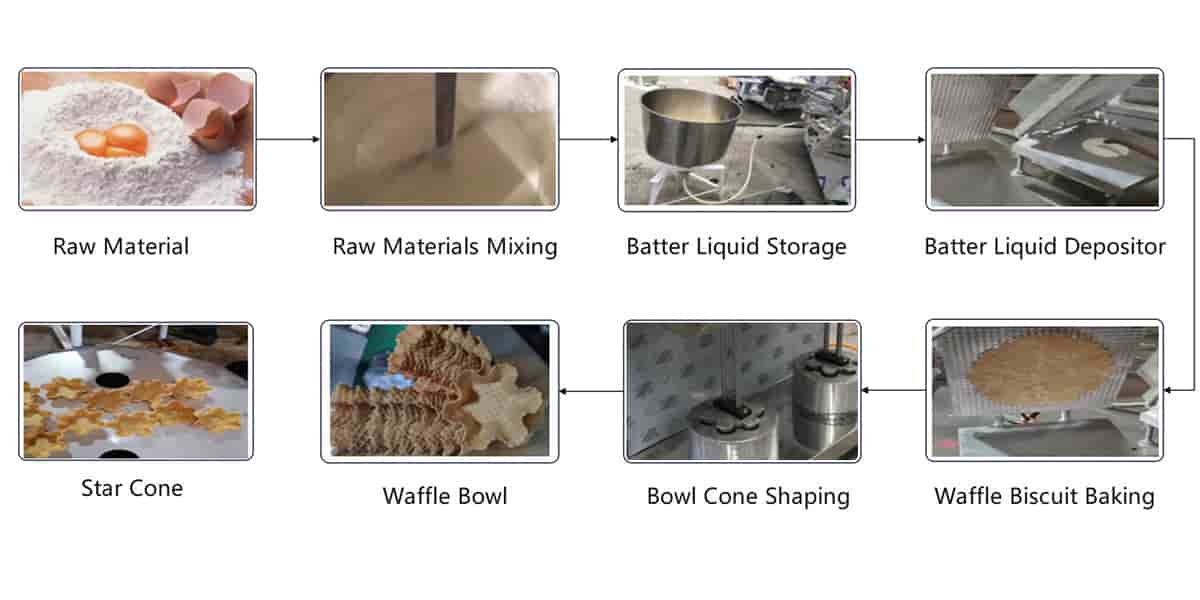

The automatic ice cream cone making machine is an upgraded version that automates key parts of the cone-making process. In full automation systems, cones are baked, shaped, and stacked without human intervention. While more expensive, these machines are ideal for large-scale producers or franchises looking to streamline their operations.

Semiautomat machines are more common in mid-size businesses. They automate baking but require manual rolling using a conical mold.

Avantaje:

- Uniform output

- Labor cost reduction

- Increased hygiene

- Higher production speed

Masă: Technical Specifications of Commercial Waffle Cone Makers

| Parametru | Specificație tipică |

|---|---|

| Model | WC-2S / WC-1A / WC-2D |

| Alimentare electrică | 220V / 50Hz or 110V / 60Hz |

| Consumul de energie | 1.2kW – 2.4kW |

| Heating Plate Material | Cast Iron / Aluminum with Teflon Coating |

| Plate Diameter | 180mm – 220mm |

| Diametrul conului (Top) | 50mm – 80mm |

| Lungimea conului | 110mm – 160 mm |

| Capacitatea de producție | 60 - 120 conuri/oră |

| Interval de temperatură | 50°C – 300°C (122°F – 572°F) |

| Sistem de control | Manual Knob / Digital Touch Panel |

| Timer | 0–5 minutes with alarm |

| Greutate netă | 15kg – 25kg |

| Dimensiuni (L×L×A) | 400×320×300 mm (variază în funcție de model) |

| Certificare | CE / UL / RoHS / ETL (varies by market) |

Stainless Steel Ice Cream Cone Baker: Built to Last

A stainless steel ice cream cone baker combines food-safe surfaces with industrial durability. Stainless steel is the gold standard in commercial kitchen appliances due to:

- Rezistență la coroziune

- Ușurință de curățare

- Aesthetic appeal

- Long service life

Look for machines that use 304-grade stainless steel, which offers superior performance in high-heat and moisture environments.

Industrial Waffle Cone Baking Equipment for Large Facilities

When operations scale up, it’s time to invest in industrial waffle cone baking equipment. These machines are suited for:

- Ice cream manufacturing plants

- Wholesale frozen dessert suppliers

- Export-oriented cone production units

Such equipment can produce hundreds to thousands of cones per hour. Some systems integrate conveyors, robotic rolling arms, and automated packaging.

Key Capabilities:

- Multiple lanes (2-12 baking heads)

- PLC touchscreen control system

- Oil spray automation

- Cooling and stacking conveyors

- Cone size customization

Electric Waffle Cone Maker vs. Gas-Powered Options

The majority of commercial cone makers are electric, but some industrial-scale units offer gas-powered heating.

Electric Models:

- Control precis al temperaturii

- Instalare ușoară

- More common for small to mid-size stores

Gas Models:

- Lower long-term operating costs (în unele regiuni)

- Faster heating

- Requires safe gas hookups and ventilation

Your choice depends on local energy prices, installation possibilities, and your production goals.

How to Use a Commercial Waffle Cone Maker (Pas cu pas)

Here’s a general workflow to operate a typical commercial waffle cone maker:

- Preheat the machine to the desired temperature (de exemplu., 180°C / 356° F.).

- Grease the plates lightly if needed.

- Se toarnă aluatul (usually about 1/4 ceaşcă) into the center of the plate.

- Închideți capacul and set the timer (60–90 seconds typical).

- Open the lid, remove the waffle sheet with a spatula.

- Roll the cone using a conical mold while still warm and pliable.

- Let cool on a rack until crisp.

Always refer to the manufacturer’s instructions, as baking time and temperature may vary by model.

Waffle Cone Batter Tips for Commercial Quality

The best machine can’t save a bad batter. To make perfect waffle cones:

- Use high-fat butter or oil for crispness

- Sugar content should be high enough to caramelize

- ouă add flavor and golden color

- Făină: Use cake flour for tenderness

- Rest the batter for at least 30 minutes before use

You can also customize with cocoa, matcha, red velvet, or charcoal powder to create signature cones.

Cleaning and Maintenance of Waffle Cone Makers

Proper maintenance ensures long-lasting use and food safety:

Curățare zilnică:

- Turn off and unplug the machine.

- Let it cool down slightly but clean while warm.

- Wipe the plates with a soft damp cloth—no metal scrapers!

- Use mild detergent if needed.

- Wipe exterior with a food-safe stainless steel cleaner.

Weekly or Periodic:

- Check power cords and controls for wear.

- Tighten any loose screws or hinges.

- Re-season cast iron plates (dacă este cazul).

Never immerse the machine in water or use harsh chemicals.

Choosing the Right Waffle Cone Maker for Your Business

When selecting the best machine, luați în considerare acești factori:

| Criterii | Recomandări |

|---|---|

| Daily Output Needed | 50–100 cones/hour: single plate machine |

| 100–300 conuri/oră: dual plate or automatic | |

| 1000+ conuri/oră: industrial line | |

| Dimensiunea conului | Choose adjustable mold machines |

| Sursa de energie | Electric for most, gas for factories |

| Ușurință de utilizare | Look for digital control and timer |

| Igienă & Safety Certs | CE, ETL, UL, food-grade coating |

| Buget | $200–$500 for small machines; $2000+ for automatic systems |

Concluzie: Invest in Efficiency and Flavor

A commercial waffle cone maker is not just a piece of equipment—it’s a value generator. It helps elevate your product, impress customers, streamline workflow, and improve margins. Whether you’re a startup ice cream shop or a large-scale dessert manufacturer, there’s a model out there tailored to your needs.