Introduction to Water Bottle Filling Machine

A water bottle filling machine is a core component of modern beverage and bottled water industries. These machines are responsible for efficiently and accurately filling various types of bottles with purified water, mineral water, or flavored water. Whether you run a small-scale bottling facility or a large-scale industrial plant, selecting the right water bottle filling machine is critical for quality, produtividade, e conformidade.

Neste guia abrangente, we will explore everything you need to know about water bottle filling machines, including their types, princípios de funcionamento, Parâmetros técnicos, customization options, and real-world RFQ examples. This guide is ideal for manufacturers, exportadores, startup founders, and engineers.

Understanding Automatic Water Bottle Filling Machine

What is an Automatic Water Bottle Filling Machine?

An automatic water bottle filling machine is designed to handle high-speed filling operations without the need for constant human intervention. It integrates bottle rinsing, liquid filling, and capping into one seamless process, often referred to as a “3-in-1 monoblock.”

Principais benefícios

- High production output

- Consistent filling accuracy

- Integrated cleaning systems (CIP/SIP)

- Minimal labor requirements

- PLC control with touchscreen interface

Aplicações

- Bottled mineral water

- Purified drinking water

- Sparkling water

- Flavored water

Types of Water Bottle Filling Machines

Based on Bottle Size and Production Capacity

Small Scale Water Bottle Filling Machine

Designed for startups, small businesses, and water shops.

Características:

- Capacidade: 200–1500 BPH (bottles per hour)

- Manual or semi-automatic models

- Ideal for 200ml–1L bottles

Medium Capacity Bottle Filling Machine

Suited for mid-level production plants.

Características:

- Capacidade: 2,000–8,000 BPH

- Automatic rinse-fill-cap cycle

- Optional labeling and packaging modules

Industrial Water Bottle Filling Machine

These are fully automatic high-capacity lines.

Características:

- Capacidade: 10,000–24,000 BPH

- Suitable for round, quadrado, or custom bottle shapes

- Heavy-duty construction with 24/7 operation support

Based on Bottle Type

- PET bottle filling machine

- Glass bottle filling machine

- HDPE bottle filling machine

- Gallon (5L–20L) bottle filling machine

Advanced Features in Liquid Bottle Filling Machine

Precision Filling Technology

Dependendo do tipo de máquina, various filling methods are used:

- Gravity filling (for still water)

- Overflow filling (for level accuracy)

- Vacuum filling (for glass bottles)

- Piston or servo filling (for flavored water with additives)

Capping Systems

- Screw capping

- Press capping

- Flip-top capping

- ROPP capping

Smart PLC Controls

- Siemens, Mitsubishi, or Delta PLC systems

- HMI touchscreen for parameter settings

- Real-time diagnostics

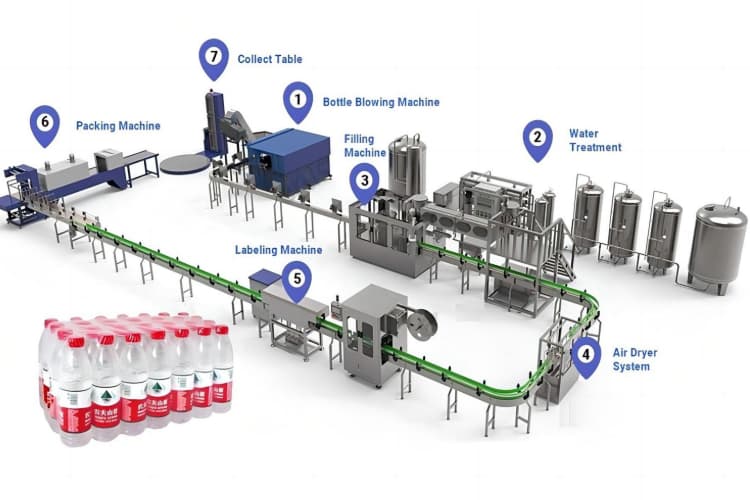

Integration with Other Equipment

- Bottle unscrambler

- Máquina de rotulagem

- Shrink sleeve applicator

- Date coder or laser printer

- Shrink wrap packaging

Technical Specifications of Water Bottle Filling Machines

| Especificação | Detalhes |

|---|---|

| Modelo | CGF18-18-6 / CGF24-24-8 / CGF32-32-10 |

| Capacidade (BPH) | 3,000 - 24,000 |

| Bottle Type | BICHO DE ESTIMAÇÃO, Glass, HDPE |

| Bottle Volume Range | 200ml – 2L |

| Rinsing Stations | 12–40 nozzles |

| Filling Accuracy | ±1% |

| Capping Stations | 6–15 heads |

| Main Material | SUS304 / SUS316 Stainless Steel |

| Requisitos elétricos | 380V, 3-fase, 50Hz |

| Pneumatic Requirement | 0.6–0,8 MPa |

| Painel de controle | Siemens PLC + Tela sensível ao toque IHM |

| Dimensões | 3200×2300×2200 mm (varia por modelo) |

| Peso | 3000–7000 kg |

Mineral Water Filling Machine with Integrated RO System

What is a Mineral Water Filling Machine?

This refers to machines used specifically for bottling mineral-rich water. These systems typically include water purification units like:

- Sand filters

- Carbon filters

- Reverse Osmosis (RO) sistemas

- UV sterilizers

- Ozone generators

Monoblock Machine Features

- Stainless steel 3-in-1 system

- Fully enclosed for hygiene

- HEPA filters for air purification

- Compatible with bottle sterilizers

Semi-Automatic Water Bottle Filling Machine: Low-Cost Option

When to Choose Semi-Automatic Models

- For small business operations

- Low daily output requirements

- Cost-saving scenarios

Core Features

- Foot-pedal or button-controlled filling

- One or two nozzles

- Manual bottle loading and unloading

- Simple maintenance

Saída:

- 300 para 1000 BPH

- Compatible with small and large bottles

Water Filling and Capping Machine: Combo Solutions

Advantages of Integrated Systems

- Seamless workflow

- Reduced downtime

- Better synchronization

- Manutenção mais fácil

Optional Add-ons

- Cap sterilizers

- Neck holding systems

- Servo-driven filling heads

- Custom conveyors

Gallon Bottle Filling Machine (20L/5 Gallon)

Principais recursos

- Automatic bottle decapper

- Inside and outside rinsing

- Leak detection system

- Capping with steam sterilization

Aplicações

- Commercial water stations

- Industrial water delivery systems

Saída: 100–1200 barrels/hour

Solicitações de cotação: Common Buyer Questions on Water Bottle Filling Machines

- What’s the MOQ?

- Usually 1 set

- Lead time?

- 20 para 45 days depending on model

- Can I use glass and PET bottles on the same machine?

- Sim, with custom molds and holders

- Which certifications are available?

- CE, ISO9001, Sgs, UL (a pedido)

- What spare parts are included?

- Gaskets, sensores, filling valves, capping heads

- Can I install the machine myself?

- Sim, with detailed manuals or optional on-site service

- Which PLC brand do you use?

- Siemens by default, others on request

- Does it support flavored or carbonated water?

- Custom versions available

- What bottle sizes are supported?

- 200ml to 2L standard, personalizável

- Is remote support available?

- Sim, via video or VPN-based diagnostics

Choosing the Right Water Bottle Filling Machine for Your Business

Key Factors to Consider

- Capacidade de saída

- Type of bottles used

- Filling media (still, flavored, or sparkling)

- Space availability

- Integration with purification system

Intervalo de custos (Reference)

| Tipo de máquina | Approximate Price Range |

| Semi-automático (small scale) | $1,500 - $5,000 |

| Automatic 3-in-1 (low capacity) | $8,000 - $20,000 |

| Industrial high-speed line | $25,000 - $100,000+ |

Top Manufacturers and Global Suppliers

- Máquina de alimentos DT (China)

- Krones AG (Alemanha)

- Sidel (França)

Industry Trends and Innovations

- IoT-enabled diagnostics and monitoring

- Energy-saving servo drives

- Tool-free changeover systems

- Integration with AI-based QC inspection

- Paperless documentation and traceability

Pensamentos finais

A water bottle filling machine is a critical investment in your production line. Choosing the right model based on capacity, bottle type, nível de automação, and budget will ensure smooth operations and high ROI. Whether you’re looking for an entry-level semi-auto machine or a complete high-speed filling line, there’s a solution tailored to your needs.

Always validate your supplier’s credentials, request full technical documents, and ask detailed RFQ questions before making a purchase.