1. Introdução

The frozen dessert market is expanding at an unprecedented rate. From local ice cream parlors to large fast-food chains, the humble ice cream cone remains a favorite among all demographics. As the demand for innovative cone designs and mass production grows, investindo em um ice cream cone maker machine has become a strategic move for entrepreneurs and investors alike.

This analyzes the economic viability of such an investment, providing insights into the market potential, expected returns, and strategies to maximize profitability.

2. Global Ice Cream Market Overview

- Valuation (2025): $93.2 bilhão (estimated by Statista)

- Growth rate: CAGR of 5.6% through 2030

- Key markets: EUA, Europa, China, Índia, Brazil

- Trends: Personalização, organic ingredients, premium cones, vegan options

Cones are a crucial element in this ecosystem—not just as a vessel but as an experience enhancer. Their production and variety significantly influence brand differentiation.

3. The Rising Demand for Ice Cream Cones

Consumers are moving away from cups to cones for a tactile, waste-free, and photo-worthy experience. Market data suggests:

- Cone-based servings account for over 60% of street-sold and parlor ice cream sales.

- Export demand for cones in regions like Africa, Sudeste Asiático, and the Middle East has grown due to rising temperatures and consumer spending.

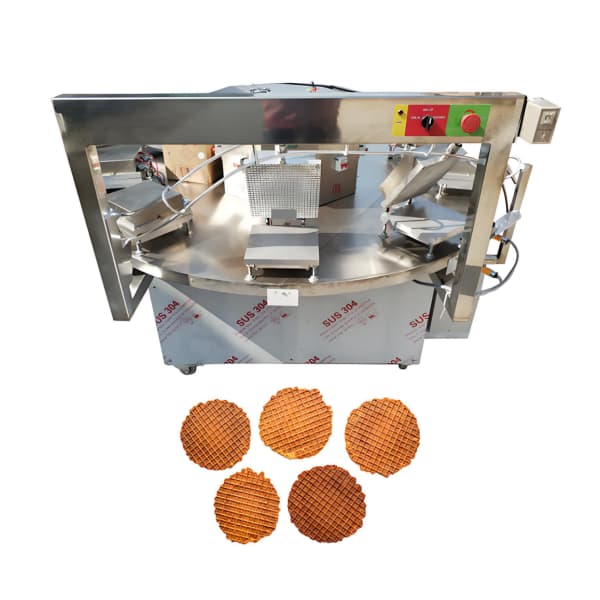

4. What is an Ice Cream Cone Maker Machine?

Um Ice Cream Cone Maker Machine is an industrial device that automates the production of ice cream cones from batter preparation to molding and baking. The machine can:

- Produce Cones de açúcar, Cones de wafer, egg roll cones, and even custom-designed cones

- Operate continuously for large-scale production

- Be fully automated or semi-automatic

Types of machines include:

- Rotary Cone Machines (high volume)

- Automatic Flat Cone Machines

- Roller Type Machines (suitable for hand-rolled cones)

5. Investment Rationale

1. Baixo custo de matéria-prima

Farinha, açúcar, óleo, and eggs are inexpensive and globally accessible.

2. High Demand

Retail and food service sectors constantly need cone supplies.

3. Escalabilidade

Start small and expand to fully automated lines with minimal disruption.

4. Long-Term Profitability

Machines have a lifespan of 7-10 years with proper maintenance, generating consistent ROI.

6. Profitability Analysis

Average Selling Price per Cone (Wholesale):

- $0.03 para $0.08, depending on region and size

Capacidade de produção:

- 2000 para 8000 cones/hora, dependendo do modelo

Saída diária (8-hour shift):

- Average: 16,000 para 64,000 cones

Daily Revenue Estimation:

- Low-end pricing: 16,000 x $0.03 = $480/day

- High-end pricing: 64,000 x $0.08 = $5,120/day

Monthly Revenue Potential (26 dias úteis):

- Faixa: $12,480 - $133,120

7. Cost Breakdown of an Ice Cream Cone Production Business

| Cost Item | Custo estimado (USD) |

|---|---|

| Cone Maker Machine (Auto) | $10,000 - $50,000 |

| Matérias-primas (Mensal) | $3,000 - $7,000 |

| Eletricidade & Utilitários | $1,000 - $2,000 |

| Trabalho (2–4 operators) | $1,500 - $4,000 |

| Embalagem | $800 - $2,000 |

| Rent (Opcional) | $500 - $2,000 |

| Manutenção (Anual) | $1,000 - $2,500 |

8. ROI Calculation: Example Case Study

Machine Price: $30,000

Receita mensal: $30,000

Monthly Operating Cost: $8,000

Monthly Net Profit: $22,000

Período de retorno: Less than 2 meses

Annual Net Profit Potential: $264,000+

Even with conservative numbers, ROI is achieved quickly—making it one of the most profitable food processing investments under $50,000.

9. Key Features and Technical Parameters

| Recurso | Especificação |

|---|---|

| Fonte de energia | 380V / 50Hz / 3 Fase |

| Método de aquecimento | LPG/Natural Gas or Electric |

| Capacidade | 2000–8000 unidades/hora |

| Faixa de tamanho de cone | 30mm – 180mm |

| Painel de controle CLP | Sim |

| Material | Aço inoxidável 304 |

| Controle de temperatura | Automático |

Machines can be customized with cone molds of different shapes and textures to suit branding needs.

10. Production Line Workflow

- Preparação de massa – Automated mixing system

- Moldagem & Cozimento – Heat plates shape and bake cones

- Rolar ou Dobrar – Based on desired style

- Resfriamento & Secagem – Cones are air-cooled to maintain crispness

- Empilhamento & Embalagem – Manual or robotic arms can be added

- Quality Check – Sensor-based or manual inspection

11. Market Entry Strategies

- B2B Supply Chain: Partner with ice cream manufacturers, padarias, and fast-food chains

- Export-Oriented Production: Tap into demand from Africa, o Oriente Médio, and South Asia

- Private Label Contracts: Manufacture cones for branded dessert companies

- Franchise Supply: Become the exclusive cone supplier for chain stores

12. Target Customer Segments

- Fabricantes de sorvete

- Local Ice Cream Kiosks

- Frozen Dessert Brands

- Hotel and Resort Caterers

- B2B Wholesale Distributors

- Export Agencies

13. Quality Standards and Compliance

To ensure market success and exports:

- Seguir HACCP e ISO 22000 para segurança alimentar

- Usar BPA-free, food-grade molds

- Ensure CE/UL certification for electrical safety

- Register with FDA or local food authority

14. Risks and Mitigation Strategies

| Risk | Solução |

|---|---|

| Equipment Downtime | AMC or in-house technician |

| Market Saturation | Product diversification (tigelas de waffle) |

| Regulatory Delays | Work with compliance consultant |

| Seasonal Demand Dip | Use for biscuit/wrap cone production |

15. Maintenance and Lifespan

Com manutenção regular:

- Expected lifespan: 7–10 anos

- Downtime/year: <3%

- Spare parts cost/year: <$1,000

Preventive maintenance includes:

- Limpeza diária

- Monthly lubrication of bearings

- Bi-annual electrical component check

16. Why Now is the Best Time to Invest

- Rising Global Temperatures: Boost ice cream sales

- Small Capital, High Returns

- Increased Demand for Artisanal Cones

- Boom in Export Markets for Cones

- Recession-Proof Business: Food treats remain popular even during downturns

17. Conclusão

Investir em um ice cream cone maker machine is not just about making cones—it’s about entering a scalable, rentável, and globally in-demand food manufacturing niche. Com o equipamento certo, marketing strategy, and cost control, you can generate substantial returns with low operational risk.

Whether you’re a food entrepreneur, an SME investor, or an export-focused manufacturer, this machine can be your gateway to a sweet return on investment.