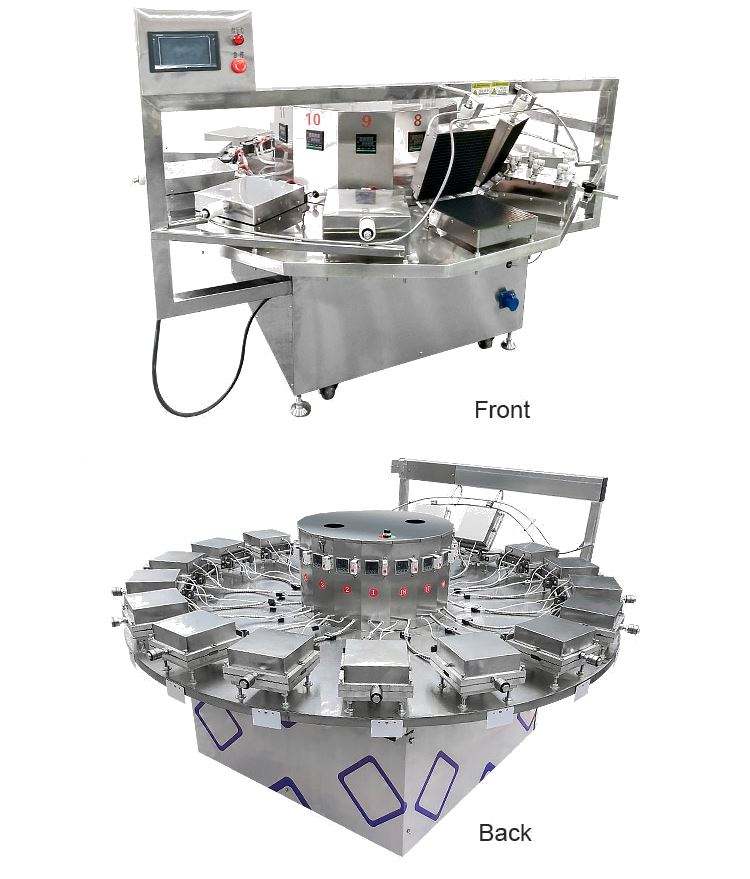

Máquina automática de casquinha de sorvete para produção comercial

Um máquina automática de casquinha de sorvete fornece uma solução perfeita para produção de cones em larga escala. A máquina mistura massa, assa uniformemente, e molda cones automaticamente. Ao contrário dos modelos manuais, máquinas automáticas reduzem trabalho, melhorar a higiene, e aumentar a produção.

Características da máquina automática de casquinha de sorvete

- Sistema de controle CLP para operação automática.

- Ajuste de temperatura para textura de cone precisa.

- Alta capacidade de produção, até 12,000 peças por hora.

- Opções de aquecimento a gás ou elétrico dependendo da preferência energética.

Parâmetros técnicos da máquina automática de casquinha de sorvete

| Modelo | Capacidade (peças/hora) | Poder (kW) | Tensão (V/Hz) | Tamanho do cone (milímetros) | Método de aquecimento | Dimensões (milímetros) | Peso (kg) |

|---|---|---|---|---|---|---|---|

| ACM-40 | 2,000 - 3,500 | 4.0 | 220V / 50Hz | 45–110 | Elétrica/Gás | 1600×1000×1300 | 420 |

| ACM-80 | 5,000 - 6,500 | 7.5 | 380V / 50Hz | 50–125 | Gás/Elétrico | 2500×1500×1700 | 820 |

| ACM-120 | 8,000 - 10,000 | 10.5 | 380V / 50Hz | 55–140 | Gás/Elétrico | 3500×1900×2000 | 1,450 |

Fabricante comercial de casquinha de sorvete para pequenas e médias lojas

UM fabricante de casquinha de sorvete comercial é ideal para pequenas e médias empresas. Estas máquinas combinam acessibilidade com capacidade de produção moderada.

Vantagens da máquina comercial de casquinha de sorvete

- Design compacto, economizando espaço na loja.

- Operação fácil de usar com controles simples.

- Produção moderada adequada para necessidades diárias de varejo.

- Menor investimento em comparação com modelos em escala industrial.

Especificações técnicas do fabricante de cone comercial

| Modelo | Capacidade (peças/hora) | Poder (kW) | Tensão (V/Hz) | Tamanho do cone (milímetros) | Dimensões (milímetros) | Peso (kg) |

|---|---|---|---|---|---|---|

| DT-6.9.15 | 600 - 1,200 | 2.5 | 220V / 50Hz | 45–100 | 1200×700×1000 | 200 |

| DT-18 | 1,200 - 2,000 | 3.5 | 220V / 50Hz | 50–120 | 1500×900×1100 | 320 |

Fabricante industrial de casquinha de sorvete para fábricas de grande escala

O fabricante de casquinha de sorvete industrial é projetado para fábricas que produzem cones a granel. Estas máquinas muitas vezes integram-se em linhas de produção completas, incluindo misturadores de massa, fornos de cozimento, dispositivos rolantes, transportadores de resfriamento, e unidades de embalagem.

Principais benefícios da máquina industrial de casquinha de sorvete

- Capaz de produzir 10,000 - 15,000 cones por hora.

- Totalmente automático com requisitos mínimos de mão de obra.

- Moldes de cone personalizáveis para vários tamanhos e texturas de cone.

- Sistemas de aquecimento energeticamente eficientes.

Parâmetros técnicos do fabricante de casquinha de sorvete industrial

| Modelo | Capacidade (peças/hora) | Poder (kW) | Tensão (V/Hz) | Tamanho do cone (milímetros) | Método de aquecimento | Dimensões (milímetros) | Peso (kg) |

|---|---|---|---|---|---|---|---|

| DT-150 | 12,000 - 14,000 | 14.0 | 380V / 50Hz | 60–150 | Gás/Elétrico | 4500×2200×2300 | 2,100 |

| DT-200 | 15,000 - 18,000 | 18.5 | 380V / 50Hz | 65–160 | Gás/Elétrico | 5500×2500×2500 | 2,800 |

Máquina para fazer cone de waffle e máquina para fazer cone de açúcar

O Máquina de fabricação de cone de waffle é um sinônimo frequentemente usado para fabricantes de cones projetados para produzir cones de waffle texturizados. De forma similar, o máquina de assar cone de açúcar se concentra na produção de doces, cones de açúcar crocantes. Ambas as máquinas funcionam com princípios semelhantes, mas diferem em designs de moldes e adaptações de receitas.

Características da máquina de fazer cone de waffle

- Projetos de moldes em relevo para textura tradicional de waffle.

- Espessura do cone ajustável.

- Recurso opcional de cobertura de chocolate.

Características da máquina para assar cone de açúcar

- Produz fino, cones crocantes.

- Cozimento uniforme com controle automatizado de temperatura.

- Produção em alta velocidade para demanda comercial.

Fabricante de copos de wafer de sorvete e máquina formadora de cone comestível

Além dos cones, muitas empresas também usam um fabricante de copos de wafer de sorvete ou máquina formadora de cone comestível. Estas máquinas ampliam a variedade de produtos produzindo copos, tigelas, ou recipientes comestíveis de formato personalizado.

Vantagens do fabricante de copos de wafer

- Expande a oferta de produtos além dos cones tradicionais.

- Fornece recipientes comestíveis resistentes e atraentes.

- Aumenta a lucratividade atendendo aos mercados de sobremesas premium.

Manutenção da máquina de casquinha de sorvete

A manutenção adequada garante desempenho consistente e prolonga a vida útil da máquina.

- Limpeza diária: Remova os resíduos de massa das assadeiras.

- Lubrificação Regular: Aplique lubrificantes seguros para alimentos nas peças móveis.

- Verificação do sistema de aquecimento: Inspecione os componentes elétricos ou de gás regularmente.

- Calibração: Mantenha controles precisos de temperatura e tempo.

Escolhendo a máquina de casquinha de sorvete certa

Ao investir em um fabricante de cones, considerar:

- Capacidade de produção – Loja pequena vs.. fábrica industrial.

- Tipo de aquecimento – O gás é mais barato para grande produção; elétrico é mais limpo.

- Variedade de cone – Cones de açúcar, Cones de waffle, ou copos de wafer.

- Orçamento & Espaço – Pegada e investimento da máquina.

- Suporte pós-venda – Garantir que o fornecedor ofereça suporte técnico e peças de reposição.

Tendências futuras na tecnologia de fabricação de casquinha de sorvete

- Sistemas de controle inteligentes – Monitoramento IoT para rastreamento de desempenho.

- Produção Ecológica – Redução do consumo de energia e das emissões.

- Personalização – Crescente demanda por cones aromatizados ou moldados.

- Integração – Fabricantes de cones integrados em linhas automatizadas de sobremesas.

Escolha-nos fabricante de máquina de sorvete DT Food Machine

O fabricante de casquinha de sorvete revolucionou a indústria de sobremesas congeladas ao permitir produtos de alta qualidade, higiênico, e produção em larga escala de cones. De fabricantes automáticos de casquinha de sorvete para grandes fábricas máquinas comerciais de cone de waffle para lojas locais, essas máquinas fornecem uma ampla gama de soluções para atender diversas necessidades de negócios. Considerando parâmetros técnicos, metas de produção, e recursos da máquina, as empresas podem selecionar o equipamento certo para aumentar a eficiência e a lucratividade.