Na indústria de processamento de alimentos em constante evolução, a automação desempenha um papel crucial no atendimento às crescentes demandas por higiene, consistência, e velocidade. O Máquina de fazer casquinha de sorvete totalmente automática permanece como um testemunho desta revolução tecnológica. Esteja você administrando uma pequena padaria ou uma instalação de produção de alimentos em grande escala, adotar esta máquina garante a produção de cones de alta qualidade com mínimo trabalho e máxima eficiência.

Aqui, discutimos profundamente os recursos, formulários, Especificações técnicas, e benefícios da máquina, ao mesmo tempo que cobre suas palavras-chave de cauda longa e sinônimos relacionados para melhor compreensão.

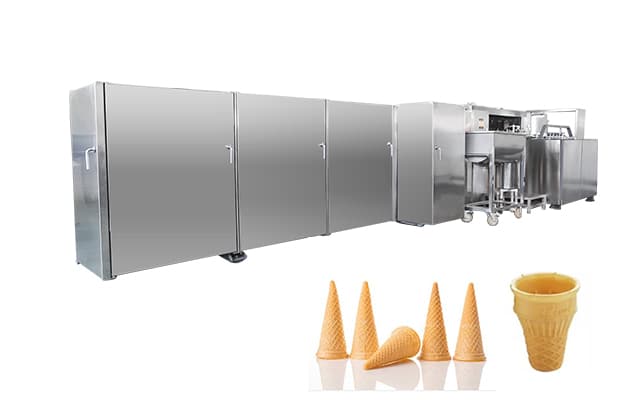

Linha de produção automática de casquinha de sorvete

O linha de produção automática de casquinha de sorvete é uma solução completa que automatiza todas as etapas da fabricação de cones - desde a mistura da massa, cozimento, rolando, até o empilhamento final. Aumenta significativamente a produção, mantendo a uniformidade na forma, tamanho, e gosto.

Componentes-chave da linha de produção:

- Sistema de mistura de massa: Mistura os ingredientes até ficar homogêneo, massa consistente.

- Sistema de cozimento: Usa placas rotativas ou fornos de túnel.

- Unidade de formação e laminação: Rola automaticamente folhas assadas em cones.

- Sistema de resfriamento e empilhamento: Resfria os cones e os empilha para embalar.

Esta solução completa permite que os fabricantes aumentem a produção e reduzam a dependência do trabalho manual.

Máquina industrial de casquinha de sorvete para produção de alto volume

O máquina industrial de casquinha de sorvete foi projetado para uso pesado. Estas máquinas são construídas com corpos robustos de aço inoxidável e apresentam vários moldes de cozimento (de 12 para 60+ pratos) para acomodar diferentes demandas de produção.

Características:

- Adequado para produzir cones de açúcar, Cones de waffle, e cones crocantes.

- Sistema de controle PLC para fácil operação e monitoramento.

- Controles variáveis de temperatura e velocidade.

- Pré-aquecimento e cozimento rápidos (tão baixo quanto 1.5 minutos por ciclo).

- Opção para personalizar o tamanho do cone, grossura, e textura.

O design industrial garante durabilidade, higiene, e cumprimento das normas de segurança alimentar.

Máquina elétrica de casquinha de sorvete para eficiência energética

Embora as máquinas tradicionais muitas vezes dependessem de aquecimento a gás, o máquina elétrica de casquinha de sorvete oferece um limpador, mais seguro, e opção mais eficiente em termos energéticos. Estas máquinas são ideais para ambientes onde o uso de gás é limitado ou indesejável.

Vantagens dos modelos elétricos:

- Controle preciso de temperatura por meio de termostatos digitais.

- Emissões e níveis de ruído reduzidos.

- Mais fácil de instalar e manter em comparação com modelos a gás.

- Mais adequado para configurações internas e fechadas.

Os fabricantes de cones elétricos são perfeitos para fabricantes ambientalmente conscientes que buscam uma produção sustentável.

Máquina de fazer cone de waffle: Cones Crocantes e Personalizáveis

Frequentemente usado de forma intercambiável com cones regulares, Cones de waffle tem uma textura e sabor distintos. O Máquina de fabricação de cone de waffle atende especificamente a este nicho, permitindo que as empresas ofereçam opções de cone premium.

Opções de personalização de cone de waffle:

- Comprimento do cone: 90mm–160mm

- Diâmetro superior: 30mm–70mm

- Grossura: 1mm–3mm

- Padrão: Favo de mel ou espiral

Os cones de waffle atraem marcas gourmet e sorveterias artesanais que querem diferenciar suas ofertas.

Máquina para assar cone de açúcar: Para amantes de cone clássico

O máquina de assar cone de açúcar é construído para criar o doce clássico, cones crocantes encontrados na maioria dos ambientes comerciais. Esses cones são feitos com uma massa doce que é assada uniformemente e fica crocante, textura dourada.

Características:

- Distribuição uniforme de calor nas placas de cozimento.

- Tempo de cozimento rápido (8–15 segundos por cone).

- Ejeção de cone totalmente automatizada.

- Desperdício mínimo devido à dispersão uniforme da massa.

As casquinhas de açúcar continuam a dominar o mercado global de casquinhas de sorvete, tornando esta máquina um produto básico na indústria.

Tabela de especificações técnicas: Máquina de casquinha de sorvete totalmente automática

Abaixo está um gráfico de especificações gerais para um modelo popular de máquina de casquinha de sorvete totalmente automática. Observe que as especificações podem variar de acordo com o modelo e fabricante.

| Especificação | Detalhes |

|---|---|

| Número do modelo | DT-ICCM36 |

| Capacidade de produção | 3000–6000 cones/hora |

| Número de placas de cozimento | 36 / 40 / 60 (personalizável) |

| Comprimento do cone | 90mm – 160 mm |

| Diâmetro do Cone | 20mm – 60 mm |

| Tempo de cozimento por ciclo | 1.5 - 2 minutos |

| Fonte de energia | Elétrico / Gás |

| Tensão | 220V / 380V, 50Hz / 60Hz |

| Consumo total de energia | 12 KW - 24 kW |

| Material | Aço inoxidável (Grau Alimentar 304) |

| Sistema de controle CLP | Sim (Painel IHM com tela sensível ao toque) |

| Dimensões | 3200mm x 1600 mm x 2200 mm |

| Peso líquido | Aprox. 2500 kg |

| Sistema de resfriamento | Ventiladores refrigerados a ar opcionais |

| Nível de ruído | ≤ 65 dB |

| Certificações | CE / ISO9001 / Sgs |

Este layout técnico ajuda os engenheiros, compradores, e equipes de manutenção para avaliar a adequação da máquina ao seu local de produção.

Máquina formadora automática de casquinha de sorvete: Forma perfeita sempre

O unidade formadora de cone nessas máquinas garante que cada cone tenha o formato espiral perfeito. Mecanismos de formação automatizados evitam quebras, aumentar a produtividade, e permitir um produto consistente.

Benefícios:

- Moldes em formato de cone personalizáveis (apontado, plano, curvado).

- Manuseio humano mínimo — produção higiênica.

- Os braços rolantes inteligentes adaptam-se a diferentes materiais de cone.

Isto é especialmente importante para empresas que vendem cones de marca que exigem uma estética consistente..

Máquina laminadora de casquinha de sorvete de alta velocidade

O unidade de laminação de cone de alta velocidade desempenha um papel crucial na transformação das folhas planas assadas no icônico formato de cone. Velocidade e precisão são fundamentais em operações de alto rendimento.

Velocidade & Recursos de eficiência:

- Pode rolar de 60 a 100 cones por minuto.

- Alinhamento preciso para minimizar o desperdício do cone.

- Compatível com selecionadores de braços robóticos para empilhamento.

Máquinas equipadas com módulos de laminação de alta velocidade podem triplicar a produção com menores custos de mão de obra.

Equipamento comercial de casquinha de sorvete para produção em larga escala

Ao dimensionar operações, equipamento comercial de casquinha de sorvete torna -se essencial. Estas máquinas destinam-se à integração em linhas de produção com outras máquinas de processamento de alimentos, como sistemas de embalagem e aromatização..

Capacidades de integração:

- Ligado a correias transportadoras para estações de embalagem.

- Sistemas de código de barras e código QR para rastreamento de lote.

- Sistemas de monitoramento de temperatura em tempo real, umidade, e saída.

Essas integrações permitem total rastreabilidade e eficiência na fabricação de alimentos.

Máquina de fazer cone para uso em fábrica de alimentos

Projetado com fábricas de alimentos em mente, essas máquinas oferecem Compatível com GMP, fácil de limpar, e operação automatizada recursos que reduzem riscos e melhoram a consistência da saída.

Design para Fábricas:

- Design de lavagem com formas de cozimento removíveis.

- Design modular para fácil substituição de peças.

- Sistemas de parada de emergência e alarme de falha.

Estas máquinas cumprem rigorosas normas de segurança alimentar, garantindo sem riscos, produção em grande escala.

Vantagens de usar máquinas de fabricação de casquinhas de sorvete totalmente automáticas

- Redução de custos trabalhistas: Intervenção humana mínima.

- Alta eficiência: Até 6000 cones/hora.

- Produção Higiênica: Atende aos padrões globais de segurança alimentar.

- Personalização: Tamanho do cone, grossura, e padrões.

- Interface amigável: IHM com tela sensível ao toque & Controles de PLC.

- Durabilidade: Construído com aço inoxidável resistente à corrosão.

Aplicações em diferentes setores

| Setor | Uso |

|---|---|

| Fabricantes de sorvete | Produção em massa de cones para sorvetes embalados ou em colher |

| Lojas de sobremesas | Cones personalizados ou premium em formato de waffle ou cone de açúcar |

| Empresas de exportação de alimentos | Exportação a granel de cones com conformidade de segurança internacional |

| Suprimentos para hotelaria e restauração | Cadeia de fornecimento de produção de cones para hotéis e eventos |

| Redes de Franquias | Cones de marca uniformes em vários pontos de venda |

Dicas para escolher a máquina certa de casquinha de sorvete

- Variedade de cone: Decida se você quer waffle, açúcar, fundo plano, ou cones pontiagudos.

- Volume de produção: Alinhe a capacidade com sua produção diária ou horária.

- Fonte de energia: Escolha entre gás e eletricidade com base na sua configuração.

- Nível de automação: Maior automação economiza trabalho e aumenta a consistência.

- Serviço & Garantia: Opte por máquinas com garantia de 12 a 24 meses e suporte de manutenção local.

Conclusão: Invista no futuro da fabricação de cones

O Máquina de fazer casquinha de sorvete totalmente automática não é apenas uma ferramenta — é um investimento estratégico para empresas que pretendem liderar em qualidade, eficiência, e inovação. Desde a produção de pequenos lotes até instalações em escala industrial, essas máquinas oferecem desempenho incomparável, precisão, e lucratividade.

Se você está planejando agilizar sua produção de cones, reduzir custos indiretos, e melhorar a qualidade do produto, adotar uma máquina de fazer casquinha de sorvete totalmente automática é o avanço mais inteligente.