Introdução à máquina de fazer crepe

UM Máquina de fazer crepe é uma máquina profissional de processamento de alimentos projetada para produzir crepes de forma eficiente, consistentemente, e higienicamente. Crepes, conhecido por sua textura fina e versatilidade, são populares em cafés, barracas de comida de rua, lojas de sobremesas, restaurantes de fast-food, hotéis, e fábricas de alimentos industriais em todo o mundo. À medida que a demanda do consumidor continua a crescer, a produção manual de crepe não é mais suficiente para empresas que exigem alto rendimento, qualidade padronizada, e eficiência de custos.

É aqui que o máquina comercial de fazer crepe, máquina de crepe automática, e máquina industrial de fazer crepe tornam-se ferramentas essenciais. Essas máquinas ajudam as empresas a melhorar a produtividade, reduzir custos trabalhistas, e entregar crepes uniformes em grande escala.

O que é uma máquina de fazer crepe?

UM Máquina de fazer crepe é um equipamento alimentar especializado que automatiza o processo de espalhamento da massa, aquecimento, culinária, e às vezes virando crepes. Dependendo do nível de automação, pode variar de máquinas de crepe elétricas semiautomáticas para linhas de produção de crepe industrial totalmente automáticas.

Nomes alternativos comuns e palavras-chave de cauda longa incluem:

- Máquina automática de fazer crepe

- Máquina de crepe comercial

- Máquina de crepe elétrica para empresas

- Máquina de crepe industrial

- Máquina de produção de crepe

- Fabricante profissional de crepes

- Máquina de fazer crepe

Todos estes termos referem-se a equipamentos projetados para produzir crepes com espessura consistente, tamanho, e textura.

Como funciona uma máquina de fazer crepe?

O processo de trabalho de um Máquina de fazer crepe é simples, mas altamente eficiente:

- Alimentação de massa

A massa de crepe é despejada manualmente ou alimentada automaticamente na máquina através de um funil ou sistema de dosagem. - Espalhamento de massa

Um tambor giratório, rolo espalhador, ou placa de aquecimento plana distribui uniformemente a massa em uma fina camada circular. - Aquecimento e Cozinha

A máquina utiliza aquecimento elétrico ou a gás para cozinhar o crepe a uma temperatura controlada. - Virando ou descascando

Dependendo do modelo, o crepe pode ser virado automaticamente ou retirado do tambor após o cozimento. - Resfriamento e Coleta

Os crepes acabados são coletados manualmente ou transferidos para uma esteira para resfriamento e embalagem.

Este processo automatizado garante cozimento uniforme, saída estável, e elevados padrões de segurança alimentar.

Tipos de máquinas para fazer crepe

1. Máquina de fazer crepe manual e semiautomática

UM máquina semiautomática de fazer crepe geralmente requer derramamento manual da massa e remoção do crepe, mas automatiza o aquecimento e a distribuição. Estas máquinas são ideais para:

- Pequenos cafés

- Caminhões de comida

- Vendedores de comida de rua

- Empresas iniciantes

Eles são compactos, fácil de operar, e acessível.

2. Máquina comercial de fazer crepe

UM máquina comercial de fazer crepe foi projetado para uso diário contínuo. Ele oferece:

- Maior capacidade de produção

- Materiais duráveis de qualidade alimentar

- Controle preciso da temperatura

- Desempenho estável

Este tipo de fabricante de crepe para negócios é comumente usado em restaurantes, correntes de sobremesa, e shoppings.

3. Máquina de fazer crepe totalmente automática

UM máquina de fazer crepe totalmente automática integra alimentação de massa, espalhando, culinária, e descarregar em um sistema. As vantagens incluem:

- Requisito mínimo de mão de obra

- Alta consistência

- Produção contínua

- Adequado para crepes de tamanho padrão

Essas máquinas são perfeitas para operações alimentícias de médio a grande porte.

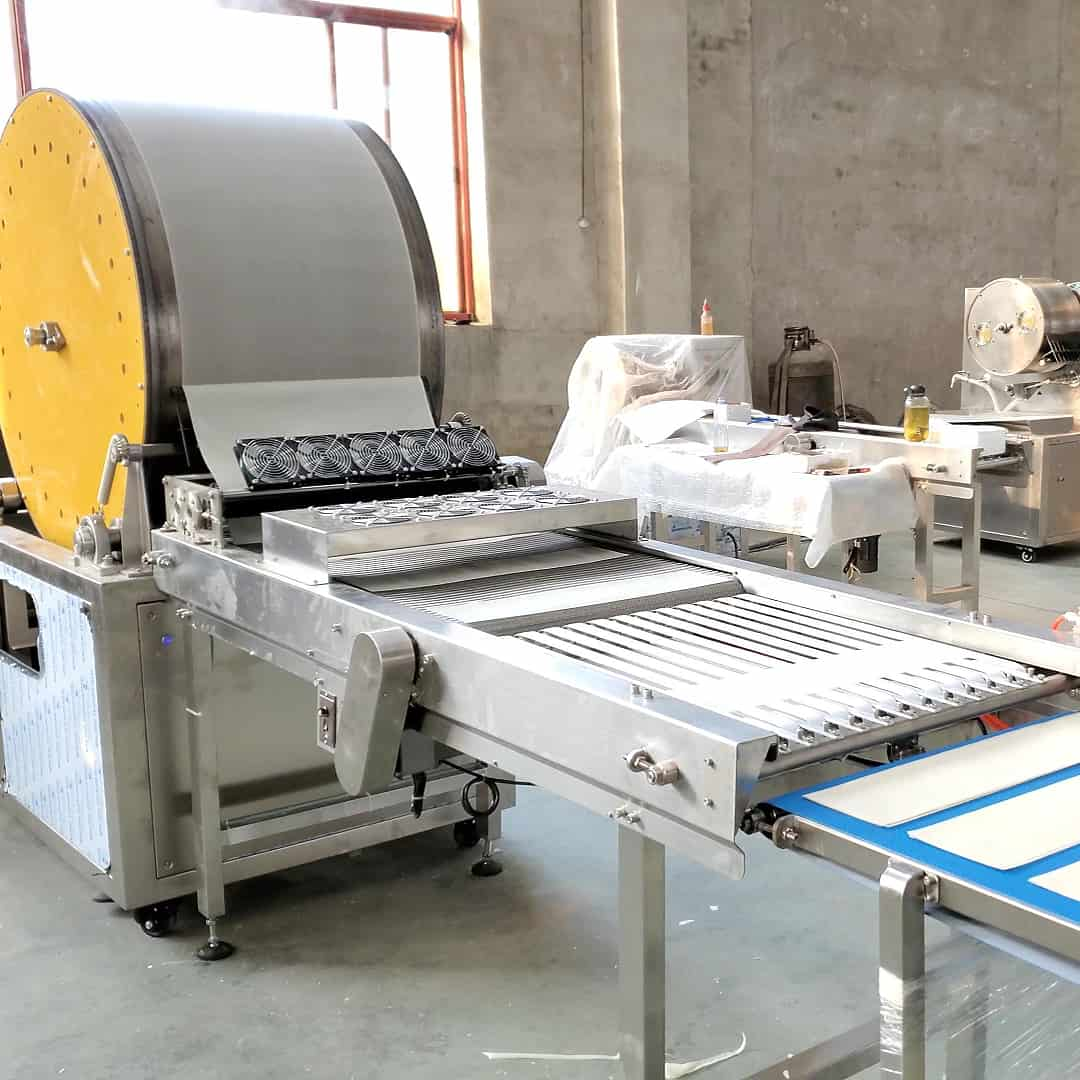

4. Máquina industrial de fazer crepe

Um máquina industrial de fazer crepe é projetado para produção em grande escala e fábricas de alimentos. Muitas vezes funciona como parte de um linha de produção de crepe e pode ser integrado com resfriamento, empilhamento, e sistemas de embalagem.

Os principais recursos incluem:

- Alta capacidade de produção

- Sistema de controle PLC

- Cozimento contínuo em tambor

- Fácil limpeza e manutenção

Principais recursos de uma máquina de fazer crepe

Um produto de alta qualidade Máquina de fazer crepe normalmente inclui os seguintes recursos:

- Estrutura de aço inoxidável de qualidade alimentar

- Controle preciso de temperatura

- Sistema uniforme de distribuição de massa

- Superfície de cozimento antiaderente

- Aquecimento com eficiência energética

- Operação estável e segura

- Fácil limpeza e manutenção

Modelos avançados também podem incluir:

- Controle de tela de toque PLC

- Espessura do crepe ajustável

- Diâmetro ajustável

- Sistema de empilhamento automático

Aplicações da máquina de fazer crepe

O Máquina de fazer crepe tem uma ampla gama de aplicações em diferentes setores:

Indústria de serviços de alimentação

- Cafés e padarias

- Lojas de sobremesas

- Restaurantes de fast food

- Hotéis e resorts

Comida de rua e varejo

- Caminhões de comida

- Mercados noturnos

- Quiosques de shopping

Indústria de Processamento de Alimentos

- Produção de crepe congelado

- Embalagem de crepe pronto para consumo

- Cozinhas centrais

- Empresas de catering

Porque os crepes podem ser doces ou salgados, o máquina de crepe comercial suporta diversas opções de menu.

Vantagens de usar uma máquina de fazer crepe

1. Maior eficiência de produção

Comparado com cozimento manual, a máquina de fazer crepe aumenta significativamente a produção e a velocidade.

2. Qualidade consistente do produto

A temperatura e o espalhamento automatizados garantem espessura e textura uniformes do crepe.

3. Custos de mão -de -obra reduzidos

Um operador pode gerenciar várias máquinas, reduzindo despesas com pessoal.

4. Melhor segurança alimentar

Materiais de qualidade alimentar e processos controlados atendem aos padrões de higiene.

5. Escalabilidade para o crescimento dos negócios

De pequenas lojas a fábricas industriais, máquinas de crepe suportam produção escalonável.

Máquina de fazer crepe vs cozimento manual de crepe

| Aspecto | Culinária Manual de Crepe | Máquina de fazer crepe |

|---|---|---|

| Saída | Baixo | Alto |

| Consistência | Instável | Uniforme |

| Custo trabalhista | Alto | Baixo |

| Higiene | Dependente do operador | Controlado |

| Escalabilidade | Limitado | Excelente |

Esta comparação mostra claramente por que as empresas preferem um máquina de fazer crepe comercial ou industrial.

Como escolher a máquina certa para fazer crepe

Ao selecionar um Máquina de fazer crepe, Considere os seguintes fatores:

Capacidade de produção

Determine quantos crepes por hora seu negócio exige.

Nível de automação

Escolha entre semiautomático, automático, ou máquinas industriais.

Fonte de energia

As máquinas elétricas de fazer crepes são mais limpas e fáceis de controlar, embora os modelos a gás possam reduzir os custos operacionais em algumas regiões.

Tamanho e espessura do crepe

Certifique-se de que a máquina suporta o diâmetro e a espessura do crepe desejados.

Suporte pós-venda

Suporte técnico confiável e disponibilidade de peças de reposição são cruciais.

Manutenção e Limpeza de Máquina de Fazer Crepe

A manutenção adequada garante longa vida útil e desempenho estável:

- Limpe a superfície de cozimento diariamente

- Verifique os elementos de aquecimento regularmente

- Inspecione componentes elétricos

- Lubrifique as peças móveis, se necessário

- Siga as orientações do fabricante

Um bem conservado máquina de fazer crepe pode operar com eficiência por muitos anos.

Tendências de mercado de máquinas de fazer crepe

O mercado global de Máquinas para fazer crepes está crescendo devido:

- Aumento da demanda por comida de rua

- Expansão das cadeias de sobremesas

- Maior automação no processamento de alimentos

- Crescimento dos mercados de alimentos congelados e prontos para consumo

As tendências futuras incluem:

- Sistemas de controle inteligente

- Projetos que economizam energia

- Máquinas multifuncionais compactas

- Integração com linhas de embalagem

Perguntas frequentes comuns sobre máquina de fazer crepe

Uma máquina de fazer crepe é fácil de operar?

Sim, a maioria das máquinas é projetada para operação simples com treinamento mínimo.

Uma máquina pode produzir diferentes tipos de crepes?

Sim, ajustando receitas e configurações de massa.

Uma máquina automática de fazer crepes é adequada para pequenas empresas?

Absolutamente. Muitos modelos automáticos compactos são ideais para startups.

Por que investir em uma máquina de fazer crepe?

UM Máquina de fazer crepe é um investimento inteligente para qualquer empresa envolvida na produção de crepe. Quer você administre um pequeno café ou uma grande fábrica de alimentos, usando um máquina de fazer crepe comercial ou industrial ajuda você a melhorar a eficiência, Garanta qualidade consistente, reduzir custos trabalhistas, e expanda seu negócio com sucesso.

Com a crescente popularidade dos crepes em todo o mundo, Escolhendo o direito máquina automática de fazer crepe pode dar à sua empresa uma forte vantagem competitiva e rentabilidade a longo prazo.