No mundo das sobremesas congeladas, apresentação e sabor são tudo. Um dos elementos mais icônicos de uma experiência de sorvete é o Cone Waffle– nítido, dourado, e recém-feito. Para empresas que buscam aumentar sua eficiência, atrair mais clientes, e melhorar a qualidade do produto, investindo em um fabricante comercial de cones é um movimento estratégico. Este guia explora tudo o que você precisa saber: tipos, características, casos de uso, conselhos de compra, e até especificações técnicas.

Fabricante profissional de casquinha de sorvete para indústria alimentícia

UM fabricante profissional de casquinha de sorvete é um eletrodoméstico de alto rendimento projetado para produzir, cones de waffle de alta qualidade. Ao contrário dos modelos domésticos, versões comerciais são construídas para suportar os rigores do dia a dia, operação contínua em ambientes de alto volume, como:

- Salões de sorvete

- Lojas de iogurte congeladas

- Cafés de sobremesas

- Caminhões de comida

- Parques temáticos e feiras

- Buffets de hotéis e resorts

O apelo dos cones recém-feitos vai além da estética. O aroma, textura, e o sabor dos cones recém-assados podem aumentar drasticamente a satisfação do cliente e até mesmo impulsionar as compras por impulso.

Máquina de cone de waffle para serviço pesado para produção de alto volume

UM máquina de cone de waffle resistente foi projetado para suportar longas horas de trabalho e retorno rápido. Os principais recursos normalmente incluem:

- Tempo de aquecimento rápido

- Placas de cozinha antiaderentes

- Controles de temperatura digitais ou manuais

- Temporizador automático com alerta sonoro

- Ferramenta de rolamento cônico ou rolo embutido

Essas máquinas geralmente são feitas de aço inoxidável ou ferro fundido, oferecendo excelente durabilidade e retenção de calor.

Benefícios das máquinas de cone de waffle para serviços pesados:

| Recurso | Vantagem |

|---|---|

| Grandes placas de cozinha | Cones maiores ou vários cones pequenos |

| Precisão de temperatura | Textura e escurecimento consistentes |

| Saída rápida | Até 120 cones por hora |

| Superfícies de fácil limpeza | Economiza mão de obra e reduz o tempo de inatividade |

| Opções de placa dupla | Asse dois cones de uma vez |

Máquina automática para fazer casquinha de sorvete: Inovação que economiza trabalho

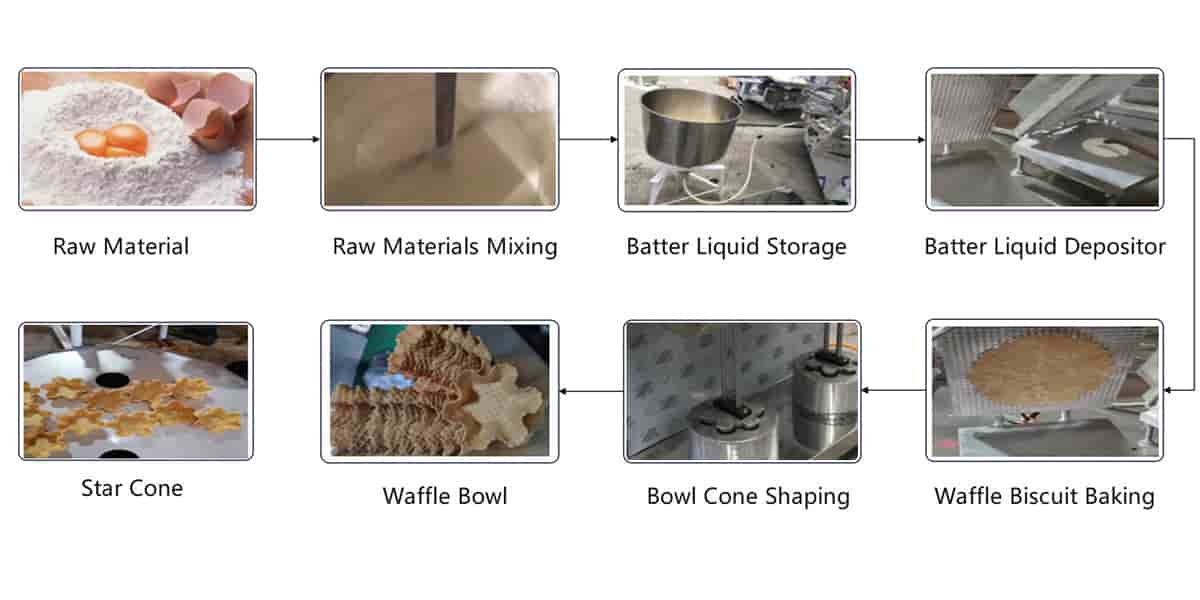

O máquina automática de fazer casquinha de sorvete é uma versão atualizada que automatiza partes importantes do processo de fabricação de cones. Em sistemas de automação completos, cones são assados, em forma, e empilhados sem intervenção humana. Embora mais caro, essas máquinas são ideais para produtores ou franquias de grande escala que buscam agilizar suas operações.

Semi-automático máquinas são mais comuns em empresas de médio porte. Eles automatizam o cozimento, mas exigem laminação manual usando um molde cônico.

Vantagens:

- Saída uniforme

- Redução de custos trabalhistas

- Maior higiene

- Maior velocidade de produção

Mesa: Especificações técnicas de fabricantes comerciais de cones de waffle

| Parâmetro | Especificação típica |

|---|---|

| Modelo | WC-2S / WC-1A / WC-2D |

| Fonte de energia | 220V / 50Hz ou 110V / 60Hz |

| Consumo de energia | 1.2kW – 2,4 kW |

| Material da placa de aquecimento | Ferro fundido / Alumínio com revestimento de Teflon |

| Diâmetro da placa | 180mm – 220 mm |

| Diâmetro do Cone (Principal) | 50mm – 80 mm |

| Comprimento do cone | 110mm – 160 mm |

| Capacidade de produção | 60 - 120 cones/hora |

| Faixa de temperatura | 50°C – 300 °C (122°F – 572°F) |

| Sistema de controle | Botão manual / Painel de toque digital |

| Temporizador | 0–5 minutos com alarme |

| Peso líquido | 15quilograma – 25kg |

| Dimensões (L × W × H.) | 400×320×300mm (varia por modelo) |

| Certificação | CE / UL / RoHS / ETL (varia de acordo com o mercado) |

Padeiro de casquinha de sorvete de aço inoxidável: Construído para durar

UM padeiro de casquinha de sorvete de aço inoxidável combina superfícies seguras para alimentos com durabilidade industrial. O aço inoxidável é o padrão ouro em eletrodomésticos de cozinha comercial devido a:

- Resistência à corrosão

- Facilidade de limpeza

- Apelo estético

- Longa vida útil

Procure máquinas que usem 304-grau de aço inoxidável, que oferece desempenho superior em ambientes de alto calor e umidade.

Equipamento industrial de cozimento de cone de waffle para grandes instalações

Quando as operações aumentam, é hora de investir equipamento industrial de cozimento de cone de waffle. Estas máquinas são adequadas para:

- Fábricas de sorvetes

- Fornecedores de sobremesas congeladas no atacado

- Unidades de produção de cone voltadas para exportação

Esses equipamentos podem produzir centenas a milhares de cones por hora. Alguns sistemas integram transportadores, braços rolantes robóticos, e embalagem automatizada.

Principais capacidades:

- Várias pistas (2-12 cabeças de cozimento)

- Sistema de controle com tela sensível ao toque PLC

- Automação de pulverização de óleo

- Transportadores de resfriamento e empilhamento

- Personalização do tamanho do cone

Fabricante de cone de waffle elétrico vs. Opções movidas a gás

A maioria dos fabricantes comerciais de cones são elétricos, mas algumas unidades em escala industrial oferecem aquecimento a gás.

Modelos Elétricos:

- Controle preciso da temperatura

- Fácil instalação

- Mais comum em lojas de pequeno e médio porte

Modelos de gás:

- Custos operacionais mais baixos a longo prazo (em algumas regiões)

- Aquecimento mais rápido

- Requer conexões seguras de gás e ventilação

Sua escolha depende dos preços locais de energia, possibilidades de instalação, e suas metas de produção.

Como usar um fabricante comercial de cone de waffle (Passo a passo)

Aqui está um fluxo de trabalho geral para operar uma típica máquina comercial de cone de waffle:

- Pré -aquecer a máquina à temperatura desejada (Por exemplo, 180°C / 356° f).

- Graxa as placas levemente, se necessário.

- Despeje a massa (geralmente sobre 1/4 xícara) no centro da placa.

- Feche a tampa e ajuste o cronômetro (60–90 segundos típico).

- Abra a tampa, remova a folha de waffle com uma espátula.

- Role o cone usando um molde cônico enquanto ainda quente e flexível.

- Deixe esfriar em uma gradinha até ficar crocante.

Consulte sempre as instruções do fabricante, pois o tempo e a temperatura de cozimento podem variar de acordo com o modelo.

Dicas para massa de cone de waffle para qualidade comercial

A melhor máquina não consegue salvar uma massa ruim. Para fazer cones de waffle perfeitos:

- Use manteiga ou óleo com alto teor de gordura para crocância

- Teor de açúcar deve ser alto o suficiente para caramelizar

- Ovos adicione sabor e cor dourada

- Farinha: Use farinha de bolo para dar maciez

- Descanse a massa por pelo menos 30 minutos antes de usar

Você também pode personalizar com cacau, matcha, Veludo vermelho, ou pó de carvão para criar cones exclusivos.

Limpeza e manutenção de fabricantes de cones de waffle

A manutenção adequada garante uso duradouro e segurança alimentar:

Limpeza diária:

- Desligue e desconecte a máquina.

- Deixe esfriar um pouco, mas limpe enquanto estiver quente.

- Limpe as placas com um pano úmido macio-sem raspadores de metal!

- Use detergente neutro se necessário.

- Limpe o exterior com um limpador de aço inoxidável adequado para alimentos.

Semanal ou Periódico:

- Verifique os cabos de alimentação e os controles quanto a desgaste.

- Aperte todos os parafusos ou dobradiças soltas.

- Retemperar placas de ferro fundido (se aplicável).

Nunca mergulhe a máquina em água ou use produtos químicos agressivos.

Escolhendo o fabricante de cone de waffle certo para o seu negócio

Ao selecionar a melhor máquina, considere esses fatores:

| Critérios | Recomendações |

|---|---|

| Produção diária necessária | 50–100 cones/hora: máquina de placa única |

| 100–300 cones/hora: placa dupla ou automática | |

| 1000+ cones/hora: linha industrial | |

| Tamanho do cone | Escolha máquinas de molde ajustáveis |

| Fonte de energia | Elétrico para a maioria, gás para fábricas |

| Facilidade de uso | Procure controle digital e temporizador |

| Higiene & Certificados de segurança | CE, ETL, UL, revestimento de qualidade alimentar |

| Orçamento | $200–$500 para máquinas pequenas; $2000+ para sistemas automáticos |

Conclusão: Invista em eficiência e sabor

UM fabricante comercial de cones não é apenas um equipamento – é um gerador de valor. Ajuda a elevar seu produto, impressionar os clientes, agilizar o fluxo de trabalho, e melhorar as margens. Quer você seja uma sorveteria iniciante ou um fabricante de sobremesas em grande escala, existe um modelo adaptado às suas necessidades.