A demanda global por manteiga de amendoim natural, manteiga de amêndoa, e os spreads de nozes mistas têm aumentado acentuadamente nos últimos anos. Como as empresas alimentícias, pequenas fábricas de processamento, e startups de manteiga de nozes expandem sua produção, investindo em um Máquina elétrica comercial de moedor de manteiga de amendoim e amêndoa torna -se essencial. Esta máquina é o equipamento principal por trás do suave, cremoso, e pastas de nozes de alta qualidade vendidas em supermercados, padarias, restaurantes, e plataformas de varejo on-line.

Hoje explicamos tudo o que você precisa saber sobre como escolher, usando, e mantendo um máquina comercial de moedor de manteiga de nozes, se você está produzindo pasta de amendoim, manteiga de amêndoa, pasta de gergelim, manteiga de caju, ou outras pastas especiais de nozes. Você aprenderá sobre os recursos da máquina, princípios de funcionamento, capacidade de produção, vantagens, campos de aplicação, dicas de compra, Insights de palavras-chave de cauda longa, e fatores técnicos que afetam a qualidade do produto final.

1. O que é uma máquina moedora elétrica comercial de manteiga de amendoim e amêndoa?

UM Máquina elétrica comercial de moedor de manteiga de amendoim e amêndoa é um equipamento industrial projetado para moer amendoim torrado, amêndoas, ou outras nozes em uma pasta lisa e uniforme. Muitos modelos adotam um estrutura do moinho coloidal com corte de alta velocidade, moagem, e mistura entre o estator e o rotor.

2. Princípio de funcionamento da máquina: Como o moedor cria uma pasta de nozes ultrafina

O processo de moagem depende rotação de alta velocidade entre o estator e o rotor dentro do moinho coloidal. Quando amendoins ou amêndoas torrados são colocados na tremonha, eles passam pela câmara de moagem onde:

- Cisalhamento forte

- Vibração de alta frequência

- Moagem ultrafina

- Força centrífuga

trabalhar simultaneamente.

Esta combinação reduz as partículas de nozes a 2–50 mícrons, proporcionando uma textura suave e sedosa semelhante às marcas comerciais premium de manteiga de nozes.

Principais benefícios do projeto do moinho coloidal

- Finura de moagem estável

- Configurações de finura ajustáveis

- Suporte contínuo à produção

- Dissipação de calor eficiente

- Longa vida útil para peças resistentes ao desgaste

Estas características fazem com que seja amplamente utilizado em fábricas de comida, startups de manteiga de nozes, Cozinhas comerciais, e linhas de processamento em pequena escala.

3. Principais aplicações da máquina comercial de moagem de manteiga de nozes

Um produto de alta qualidade moedor de porca elétrico comercial pode processar uma ampla gama de materiais além de amendoins e amêndoas.

Produtos de nozes

- Manteiga de amendoim / pasta de amendoim

- Manteiga de amêndoa

- Creme de avelã

- Manteiga de caju

- Pastas de pistache

- Pastas mistas de nozes

Pastas de sementes

- Pasta de gergelim (tahine)

- Pasta de semente de girassol

- Pasta de linhaça

Outros materiais alimentares

- Pasta de pimenta

- Pasta de gengibre

- Pasta de alho

- Pasta de chocolate

- Geléia & purê de frutas

- Leite de soja e outros alimentos líquidos

Esta flexibilidade torna o moedor uma solução de processamento multifuncional para muitas aplicações da indústria alimentícia.

4. Características de uma máquina moedora elétrica comercial de manteiga de amendoim e amêndoa de alta qualidade

Ao investir em equipamentos de moagem industrial, é essencial avaliar o design da máquina, qualidade dos materiais, e estabilidade operacional. Uma máquina confiável geralmente inclui:

4.1 Construção em aço inoxidável de alta qualidade

Grau de comida 304 ou 316 aço inoxidável garante:

- Conformidade com higiene e segurança

- Resistência à corrosão

- Durabilidade a longo prazo

4.2 Potente motor industrial

Uma máquina comercial de moedor de amendoim normalmente usa:

- 2.2 KW - 11 motores kW

- Controle de frequência de velocidade variável

- Sistemas de proteção contra superaquecimento

4.3 Controle de finura ajustável

Os operadores podem ajustar a textura de saída ajustando:

- Folga estator-rotor

- Velocidade de rotação

- Taxa de alimentação

4.4 Capacidade de produção contínua

Grandes processadores de alimentos preferem máquinas com:

- Ciclo de trabalho longo

- Sistemas refrigerados a água

- Rolamentos robustos e cabeçotes de retificação

4.5 Limpeza fácil & Manutenção

Uma máquina com cabeças de moagem removíveis e superfícies lisas de aço inoxidável reduz o tempo de inatividade e o esforço de limpeza.

5. Por que os fabricantes de alimentos escolhem máquinas industriais de moagem de manteiga de nozes

5.1 Alta eficiência e grande produção

Os moedores comerciais de manteiga de nozes apoiam as capacidades de produção de:

- 50 kg/h para pequenas oficinas

- Até 2000 kg/h para grandes fábricas de alimentos

5.2 Textura e qualidade consistentes

O tamanho uniforme das partículas garante:

- Sensação suave na boca

- Emulsificação estável

- Melhor vida útil do produto

5.3 Versatilidade para Diferentes Produtos

Uma única máquina pode lidar:

- Amendoim

- Amêndoas

- Caju

- Sésamo

- Nibs de cacau

- Pimentão e alho

5.4 Custos trabalhistas mais baixos

Sistemas de alimentação automática e operação contínua reduzem a necessidade de trabalho manual.

6. Especificações Técnicas (Modelos Típicos)

Abaixo está um exemplo de tabela de especificações técnicas frequentemente usada para máquinas comerciais de moagem de manteiga de amendoim e amêndoa.

| Modelo | Poder (kW) | Tensão | Capacidade (kg/hora) | Finura | Peso (kg) |

|---|---|---|---|---|---|

| JTM-80 | 2.2 kW | 220/380V | 50–80 kg/h | 50–100 malha | 150 kg |

| JTM-110 | 4 kW | 380V | 100–150 kg/h | 50–100 malha | 185 kg |

| JTM-130 | 7.5 kW | 380V | 300–500 kg/h | 50–150 malha | 300 kg |

| JTM-180 | 11 kW | 380V | 800–1200 kg/h | 50–150 malha | 450 kg |

Os fabricantes podem oferecer tensão personalizada ou sistemas de refrigeração a água para operações contínuas.

7. Dicas de instalação para uma máquina comercial de moagem de manteiga de nozes

A instalação adequada garante desempenho estável e longa vida útil.

7.1 Escolha um estábulo, Superfície nivelada

A máquina deve ser instalada em um plano, plataforma sem vibração.

7.2 Garanta conexões elétricas adequadas

Usar:

- Tensão correta

- Aterramento

- Dispositivos de proteção contra sobrecarga

7.3 Conectar resfriamento de água (Se aplicável)

Isso mantém a temperatura de moagem estável, prevenindo:

- Separação de óleo

- Cheiro de queimado

- Mudanças de cor

7.4 Rolamentos pré-lubrificados

Adicione lubrificação apropriada antes de começar.

7.5 Faça um teste com água ou amendoim

Para verificar:

- Finura de moagem

- Rotação suave

- Nenhum ruído incomum

8. Como operar uma máquina moedora elétrica comercial de manteiga de amendoim e amêndoa

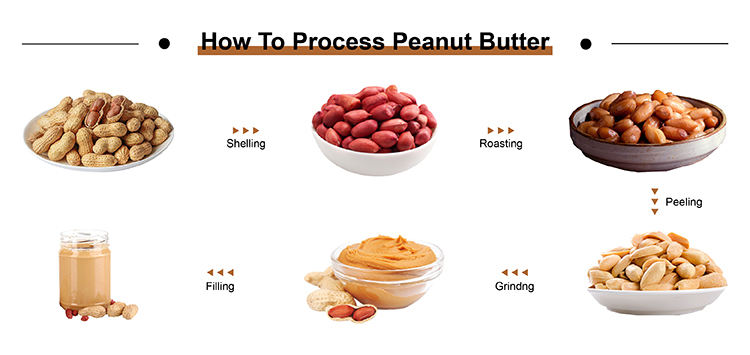

Etapa 1: Assando as nozes

Os amendoins e as amêndoas devem estar totalmente torrados:

- Remova a umidade

- Melhorar o sabor

- Melhore a eficiência da moagem

Etapa 2: Classificação & Resfriamento

Remover pedras, conchas, e impurezas.

Etapa 3: Alimentando nozes no funil

Use alimentação contínua para obter textura consistente.

Etapa 4: Ajustar finura

Altere a folga do estator-rotor de acordo com as necessidades do produto.

Etapa 5: Iniciar processo de moagem

A manteiga de nozes sai macia e quente.

Etapa 6: Segunda Moagem (Opcional)

Para manteiga de amêndoa ultrafina ou manteiga de amendoim cremosa, muitos processadores executam moagem em dois estágios.

9. Guia de manutenção para máquinas trituradoras de manteiga de nozes

A manutenção regular aumenta a vida útil da máquina e a consistência do produto.

Manutenção Diária

- Limpe a câmara de moagem

- Remover resíduos

- Verifique se há superaquecimento

- Limpe o corpo de aço inoxidável

Manutenção Semanal

- Aperte os parafusos

- Inspecione as conexões elétricas

- Verifique os níveis de lubrificação

Manutenção mensal

- Inspecione o desgaste do estator e do rotor

- Substitua as vedações se necessário

- Teste o desempenho do motor

Um moedor bem conservado pode operar de forma confiável para 8–10 anos.

10. Como escolher a melhor máquina moedora elétrica comercial de manteiga de amendoim e amêndoa

Ao selecionar equipamentos, Considere os seguintes fatores:

10.1 Capacidade de produção

Sua produção diária ou horária determina o modelo de máquina necessário.

10.2 Requisito de finura

Produtos como o creme de amêndoa requerem uma moagem mais fina do que a pasta de amendoim tradicional.

10.3 Potência e qualidade do motor

Motores industriais garantem operação contínua.

10.4 Qualidade do material

Escolha aço inoxidável de qualidade alimentar para conformidade com a segurança.

10.5 Disponibilidade de suporte pós-venda

Prefira fornecedores que ofereçam:

- Peças de reposição

- Orientação on-line

- Suporte de instalação

10.6 Orçamento e ROI

Pequenos processadores podem começar com um modelo de 50–100 kg/h, enquanto os grandes fabricantes precisam de linhas de 500–2.000 kg/h.

11. Vantagens de usar um moedor industrial de manteiga de nozes em sua linha de produção

✔ Maior consistência de produção

✔ Melhor sabor e textura

✔ Custos trabalhistas reduzidos

✔ Escalabilidade para crescimento dos negócios

✔ Padrões de produção seguros e sanitários

✔ Uso multifuncional para diferentes nozes e sementes

12. Quem precisa de uma máquina moedora elétrica comercial de manteiga de amendoim e amêndoa?

Esta máquina é ideal para:

- Produtores de manteiga de amendoim

- Fábricas de manteiga de amêndoa

- Startups de processamento de nozes

- Fabricantes de salgadinhos

- Fornecedores de ingredientes alimentares

- Padarias e fábricas de sobremesas

- Molho & oficinas de produção de pasta

- Pequenas cozinhas comerciais que produzem manteiga de nozes fresca

Máquina elétrica comercial de moedor de manteiga de amendoim e amêndoa

UM Máquina elétrica comercial de moedor de manteiga de amendoim e amêndoa é um dos investimentos mais valiosos para empresas que processam amendoim, amêndoas, castanha de caju, ou gergelim em pastas de alta qualidade. Quer você administre uma startup ou uma fábrica de alimentos em grande escala, escolher um moedor industrial confiável de manteiga de nozes melhorará sua produtividade, qualidade do produto, e eficiência geral do negócio.

Se precisar de ajuda para selecionar o modelo certo ou personalizar uma linha completa de produção de manteiga de nozes, Também posso ajudá-lo a escrever uma página completa do produto, Lista de perguntas da RFQ, ou versão em espanhol a qualquer momento.