Introdução

Nuggets de frango se tornaram um dos fast food mais populares do mundo – apreciados tanto por crianças quanto por adultos. De restaurantes e redes de fast-food a supermercados de alimentos congelados, nuggets de frango estão por toda parte. Por trás desse crocante, suculento, e lanche dourado é um avançado linha de produção de nugget de frango, projetado para garantir eficiência, higiene, e qualidade de produto consistente.

Para Fabricantes de alimentos com o objetivo de expandir seus negócios ou iniciar um novo projeto de alimentos congelados, entendendo como o linha de produção de nugget de frango obras é essencial. Este artigo irá guiá-lo através de todos os aspectos da produção de nugget de frango – desde a preparação da matéria-prima até a embalagem – incluindo a composição da máquina, Parâmetros técnicos, e como escolher o melhor fornecedor.

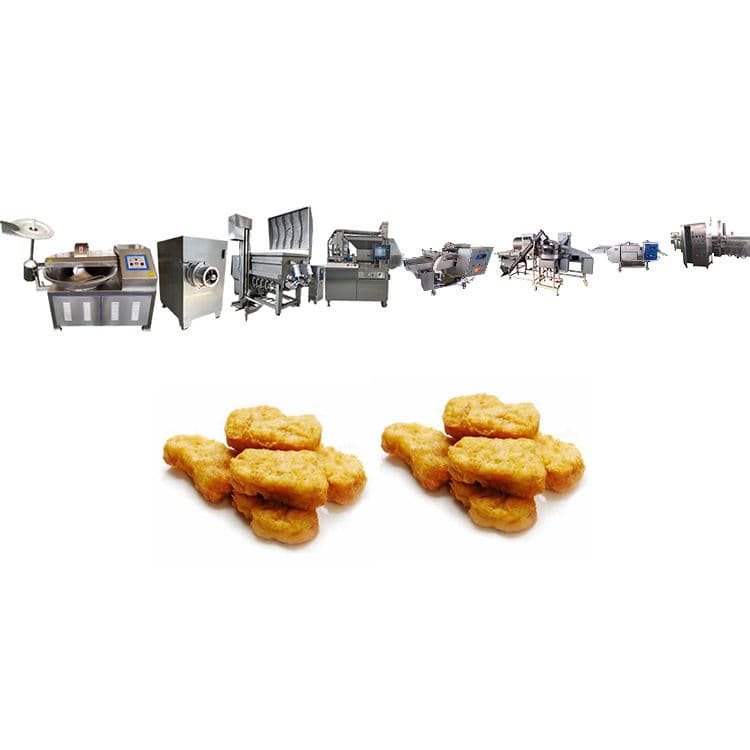

1. O que é uma linha de produção de nugget de frango?

UM linha de produção de nugget de frango é um sistema totalmente automático ou semiautomático que processa carne de frango em uniforme, revestido, e nuggets fritos prontos para congelar ou embalar. A linha integra múltiplas máquinas para realizar cada etapa do processo de forma eficiente e higiênica, garantindo qualidade consistente e capacidade de produção em massa.

A linha de produção normalmente inclui:

- Equipamento de corte e mistura de carne

- Máquina formadora

- Máquinas de bater e empanar

- Sistemas de fritura e resfriamento

- Unidades de congelamento e embalagem

Uma linha totalmente automatizada pode produzir centenas de quilos de nuggets de frango por hora com operação manual mínima.

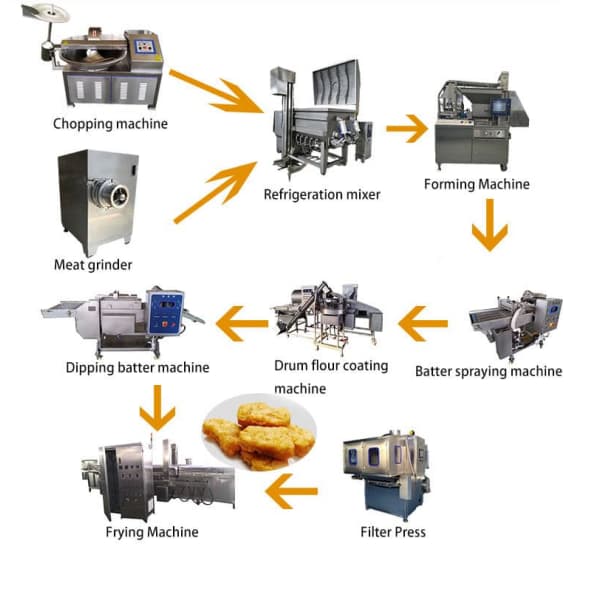

2. Principais componentes de uma linha de produção de nugget de frango

2.1 Sistema de corte e mistura de carne

Esta seção envolve cortar o peito de frango ou a carne da coxa em pedaços menores e misturá-los com temperos, amido, e agentes ligantes.

- Máquinas usadas: Moedor de carne, cortador de tigela, e misturador a vácuo.

- Função: Garante textura e sabor uniformes da pasta de frango.

2.2 Máquina formadora de nugget de frango

A máquina formadora molda a pasta de frango misturada em formas de pepita (oval, retangular, coração, ou formas personalizadas).

- Vantagens: Moldes ajustáveis, alta precisão, peso uniforme.

- Saída: 100–600 kg/h dependendo do modelo.

2.3 Máquinas para bater e empanar

Essas máquinas cobrem os nuggets com massa e pão ralado para obter aquela textura crocante característica.

- Máquina de bater: Aplica uma fina camada de massa líquida uniformemente.

- Máquina de empanar: Cobre nuggets com migalhas secas.

- Recurso: Reciclagem automática de massa e migalhas para reduzir o desperdício.

2.4 Sistema de pré-fritura e fritura profunda

A fritura dá aos nuggets a cor marrom dourada e mantém o sabor.

- Pré-fritura: Fritura curta em baixa temperatura para fixar o revestimento.

- Fritar: Fritura final para crocância e sabor.

- Faixa de temperatura: 160°C-180 °C.

- Sistema de filtragem de óleo: Mantém o óleo limpo e prolonga a vida útil do óleo.

2.5 Transportador de resfriamento

Depois de fritar, pepitas são resfriadas para remover o excesso de óleo e se preparar para congelar.

- Tipo de resfriamento: Resfriamento a ar ou resfriamento a água.

- Propósito: Evite a aderência e mantenha a integridade do produto.

2.6 Sistema de congelamento

Nuggets de frango congelados são mais fáceis de embalar e armazenar.

- Máquina: Congelador espiral ou freezer túnel.

- Temperatura: -35°C a -40°C para congelamento rápido.

- Tempo: 20–30 minutos dependendo do tamanho da pepita.

2.7 Máquina de embalagem

Etapa final – embalar os nuggets congelados para venda ou exportação.

- Tipos: Embalagem a vácuo ou embalagem tipo travesseiro.

- Opcional: Enchimento de nitrogênio para prolongar a vida útil.

3. Parâmetros técnicos da linha de produção de nugget de frango

| Modelo | Capacidade (kg/hora) | Poder (kW) | Dimensões (eu) | Material | Tensão |

|---|---|---|---|---|---|

| DT-CN100 | 100–150 | 30 | 12 × 2 × 2.3 | SUS304 | 380V / 50Hz |

| DT-CN300 | 300–500 | 55 | 18 × 2.5 × 2.5 | SUS304 | 380V / 50Hz |

| DT-CN600 | 600–800 | 85 | 25 × 3 × 2.8 | SUS304 | 380V / 50Hz |

| DT-CN1000 | 1000+ | 110 | 30 × 3.5 × 3 | SUS304 | 380V / 50Hz |

Todas as máquinas do linha de produção de nugget de frango são feitos de aço inoxidável de qualidade alimentar (SUS304) para durabilidade, higiene, e fácil limpeza.

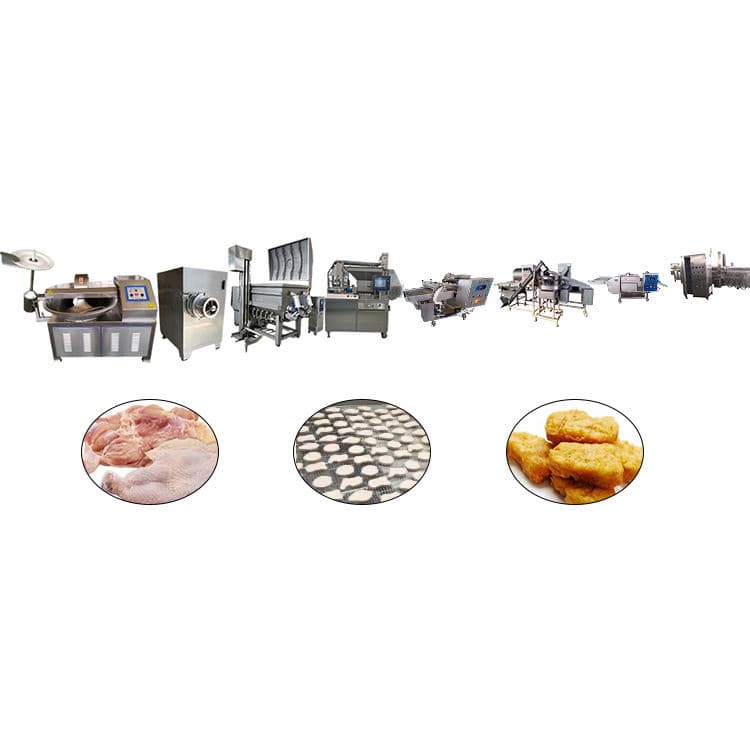

4. Fluxo de Trabalho da Linha de Produção de Nugget de Frango

- Preparação de Matéria Prima: A carne de frango é cortada, picado, e misturado com temperos.

- Formando: A máquina formadora pressiona a pasta em formato de pepita.

- Espancamento: Nuggets são revestidos com massa usando um sistema de batedura contínua.

- Empanado: Migalhas de pão são aplicadas para dar textura.

- Pré-fritura: Fritura leve para fixar o revestimento.

- Fritar: Fritura final para cor e sabor.

- Resfriamento: Óleo e umidade são removidos.

- Congelando: Nuggets são congelados rapidamente para preservar o frescor.

- Embalagem: Nuggets congelados prontos para venda são embalados e selados.

Cada etapa do linha de produção de nugget de frango é sincronizado com transportadores e sensores para produção contínua e controle preciso.

5. Vantagens de uma linha de produção de nugget de frango totalmente automática

- Alta eficiência: A operação automatizada minimiza o trabalho e aumenta a produção.

- Qualidade consistente: O controle preciso garante formato uniforme, peso, e revestimento.

- Economia de energia: Sistemas avançados de aquecimento e circulação de óleo reduzem o desperdício de energia.

- Manutenção fácil: O design modular e a construção em aço inoxidável simplificam a limpeza.

- Personalizável: Tamanho da pepita, forma, e a espessura do revestimento pode ser facilmente ajustada.

- Em conformidade com os padrões de segurança alimentar: Atende aos requisitos HACCP e CE.

6. Aplicações da Linha de Produção de Nugget de Frango

Esta linha de produção é adequada para:

- Fabricantes de alimentos congelados

- Fornecedores de fast-food

- Fornecedores de refeições escolares ou restaurantes

- Grandes fábricas de processamento de alimentos

Também pode processar produtos similares como:

- Pepitas de peixe

- Nuggets de vegetais

- Rissóis de carne

- Tempura ou salgadinhos revestidos

7. Como escolher a linha de produção certa de nugget de frango

Ao selecionar um linha de produção de nugget de frango, considere esses fatores:

- Capacidade de produção: Escolha a linha que corresponde às suas necessidades diárias de produção.

- Nível de automação: Decida entre sistemas semiautomáticos e totalmente automáticos.

- Espaço disponível: Certifique-se de que sua fábrica possa acomodar o comprimento e a altura do equipamento.

- Orçamento e custo de energia: Compare o consumo de energia e a eficiência.

- Confiabilidade do fornecedor: Trabalhe com fabricantes com experiência comprovada e serviço global.

8. Por que escolher a DT Food Machine como seu fornecedor

DT Food Machine Co., Ltda. é um fabricante e exportador líder de máquinas de processamento de alimentos com mais de 15 anos de experiência. Somos especializados em completo linhas de produção de nugget de frango e outros equipamentos alimentares, como linhas de pepitas de peixe, linhas de salgadinhos fritos, e linhas de produção de batatas fritas.

Nossas vantagens:

- Soluções Personalizadas: Projetos sob medida para fábricas de pequeno e grande porte.

- Experiência Global de Exportação: Clientes em mais 50 países.

- Suporte pós-venda: Instalação, treinamento, e serviço de peças de reposição.

- Preço competitivo: Fornecimento direto da fábrica com garantia de qualidade.

Ao escolher a DT Food Machine, você garante um desempenho confiável, excelente qualidade, e forte suporte técnico para seu projeto de nugget de frango.

9. Perguntas frequentes (Perguntas frequentes)

Q1: Qual é a capacidade de produção de uma linha de produção de nugget de frango?

UM: Dependendo do modelo, a capacidade varia de 100 kg/h para 1000+ kg/hora.

Q2: A linha pode produzir diferentes formatos de pepitas?

UM: Sim. Os moldes podem ser personalizados para diferentes formatos e tamanhos de pepitas.

Q3: Qual é o consumo de energia?

UM: A potência varia de 30 kw para 110 kW dependendo da capacidade e configuração.

Q4: É fácil limpar as máquinas?

UM: Sim. Todas as máquinas são feitas de aço inoxidável com peças fáceis de remover para limpeza.

Q5: A DT Food Machine pode fornecer instalação e treinamento?

UM: Sim. Nossos engenheiros podem orientá-lo on-line ou visitar seu local para instalação e treinamento.

10. Linha de produção de nugget de frango

UM linha de produção de nugget de frango é um investimento essencial para os fabricantes de alimentos que desejam produzir produtos de alta qualidade, consistente, e produtos lucrativos. Com automação total, sistemas de revestimento avançados, e fritadeiras energeticamente eficientes, a linha de produção garante operação suave e produção superior.

Se você está planejando iniciar ou atualizar seu negócio de nugget de frango, Máquina de alimentos DT oferece soluções chave na mão que combinam tecnologia, qualidade, e suporte — ajudando você a permanecer à frente na competitiva indústria de processamento de alimentos.