1. Introdução

O máquina de lavar bolhas vegetais e frutas é um equipamento avançado projetado para limpar produtos frescos usando uma combinação de imersão em água e agitação de bolhas de ar. Este método de limpeza é gentil, eficiente, and environmentally friendly, tornando-o adequado para produtos delicados e firmes.

As global consumers increasingly demand pronto para comer, pré-lavado, and organic-certified produce, os processadores estão atualizando da lavagem manual tradicional para a lavagem totalmente automatizada sistemas de lavagem de bolhas.

1.1 Por que a lavagem com bolhas é importante no processamento moderno de alimentos

- Conformidade com a segurança alimentar

Regulatory agencies such as the FDA, Comissão da UE, e CFIA exigem que os produtores de alimentos minimizem a contaminação microbiana, resíduos de pesticidas, e detritos físicos. - Product Quality Preservation

Bubble washing prevents bruising, descoloração, e perda de nutrientes, especially important for export markets. - Eficiência Operacional

Handles high volumes — from 500 kg/h para plantas pequenas para 10,000+ kg/h for large industrial facilities.

2. How a Bubble Washing Machine Works

UM bubble washing machine vegetable and fruit usa bolhas de ar geradas por um soprador para agitar suavemente os produtos na água, loosening dirt and contaminants.

2.1 O Fluxo do Processo

- Carregando

Produce enters via a conveyor or manual hopper. - Imersão em tanque de água

Fruits and vegetables are fully submerged. - Injeção de bolhas

Compressed air enters through perforated pipes, criando turbulência. - Separação de Sujeira

Partículas pesadas assentam, detritos leves flutuam. - Enxágue final

Sprays de água limpa removem quaisquer contaminantes residuais. - Descarga

Um transportador transfere os produtos para a próxima etapa de processamento.

2.2 Key Science Behind Bubble Cleaning

- Efeito Hidrodinâmico: Bolhas criam microcorrentes que penetram nas dobras das folhas.

- Surface Tension Reduction: Bolhas de ar reduzem a adesão entre a sujeira e produzem pele.

- Enriquecimento de oxigênio: Helps maintain freshness during cleaning.

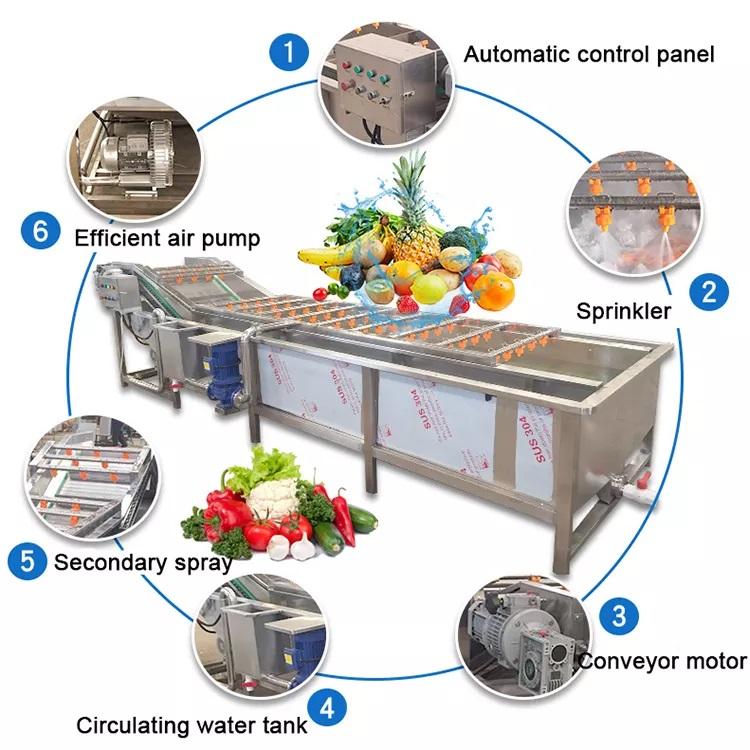

3. Projeto de Máquina & Componentes

O bubble washing machine vegetable and fruit é projetado para durabilidade, higiene, e fácil limpeza.

| Componente | Função |

|---|---|

| Tanque de água | Holds the washing solution. |

| Soprador de ar | Generates air for bubble production. |

| Transportador de malha | Moves produce through the cleaning zone. |

| Armadilha de sedimentos | Coleta detritos pesados. |

| Saída de transbordamento | Removes floating impurities. |

| Seção de enxágue | Provides final clean water spray. |

| Painel de controle | Gerencia a velocidade, fluxo de ar, e circulação de água. |

Material: Aço inoxidável SUS304 (padrão), SUS316 for highly acidic produce.

4. Tabela de Parâmetros Técnicos

| Modelo | Capacidade (kg/hora) | Poder (kW) | Volume de água (L) | Dimensões (milímetros) | Peso (kg) | Material |

|---|---|---|---|---|---|---|

| DT-500 | 500 | 2.2 | 400 | 3000×1000×1300 | 280 | SUS304 |

| DT-1000 | 1000 | 3.7 | 600 | 4000×1200×1300 | 380 | SUS304 |

| DT-2000 | 2000 | 5.5 | 900 | 5000×1400×1350 | 520 | SUS304 |

| DT-3000 | 3000 | 7.5 | 1200 | 6000×1500×1400 | 650 | SUS304 |

| DT-5000 | 5000 | 11 | 1500 | 8000×1600×1450 | 950 | SUS304 |

5. Aplicações de produtos

- Folhas verdes: Alface, espinafre, couve, repolho.

- Vegetais de raiz: Cenouras, batatas, rabanetes, beterraba.

- Frutas: Morangos, uvas, maçãs, cítrico.

- Ervas: Hortelã, manjericão, coentro.

- Plantas Medicinais: Ginseng, crisântemo.

6. Benefits Over Other Washing Methods

| Recurso | Máquina de lavar bolhas | Lavagem por spray | Lavagem manual |

|---|---|---|---|

| Danos à produção | Muito baixo | Médio | Variável |

| Limpeza completa | Alto | Médio | Baixo |

| Exigência de mão -de -obra | Baixo | Médio | Alto |

| Eficiência no uso da água | Alto | Médio | Baixo |

7. Guia de instalação

- Selecione o local – Piso nivelado, perto da água & drenagem.

- Instalar utilitários – Connect 3-phase power, entradas de água, e drenagem.

- Conjunto – Anexe o soprador, transportador, e enxágue as seções.

- Teste – Run with water only to check for leaks.

8. Dicas de operação

- Pre-rinse heavily soiled produce before loading.

- Adjust bubble intensity for delicate items.

- Keep water temperature low to maintain freshness.

9. Cronograma de Manutenção

| Freqüência | Ação |

|---|---|

| Diário | Ralo & tanque limpo, filtros de lavagem. |

| Semanalmente | Inspecione o soprador e a bomba. |

| Mensal | Remover dimensionamento, higienizar tanque. |

| Anual | Substitua as vedações, rolamentos. |

10. Água & Recursos de economia de energia

- Sistema de recirculação reutiliza até 80% de água.

- Remoção automática de detritos prolonga a vida da água.

- Velocidade variável do ventilador reduz o uso de energia.

11. Estudos de caso

Caso 1 – Leafy Green Processor in California

- Capacidade: 3000 kg/hora

- Resultado: Mão de obra reduzida por 70%, uso de água por 40%.

- ROI: Alcançado em 14 meses.

Caso 2 – Berry Exporter in Chile

- Capacidade: 2000 kg/hora

- Resultado: Reduced bruising damage from 6% para baixo 1%.

12. Tendências de mercado

- Aumento da demanda por organic-certified washed produce.

- Aumentando a adoção em Ásia-Pacífico devido aos mercados de exportação.

- Integração com máquinas de classificação óptica.

13. Como escolher a máquina certa

- Requisitos de capacidade

- Tipo de produto

- Disponibilidade de espaço

- Metas de orçamento e ROI

- Suporte pós-venda

14. Faixas de preço

- Pequeno (500–1000 kg/h): $2,500–US$ 5.000

- Médio (2000–3000 kg/h): $6,000–$ 10.000

- Grande (5000+ kg/hora): $12,000–$20.000+

15. Perguntas frequentes estendidas

Q: Can it be used for seafood?

UM: Sim, with proper corrosion protection.

Q: Can it connect to peeling machines?

UM: Sim, commonly integrated in full processing lines.

Q: Is ozone disinfection available?

UM: Sim, como um complemento opcional.

16. Guia de solução de problemas

| Problema | Possível causa | Solução |

|---|---|---|

| Bolhas fracas | Baixa pressão do soprador | Verifique o filtro do soprador |

| Limpeza ruim | Tanque sobrecarregado | Reduzir a taxa de alimentação |

| Transbordamento de água | Dreno bloqueado | Saída limpa |

17. Conclusão

UM bubble washing machine vegetable and fruit is not just a cleaning device — it’s a produtividade, qualidade, e investimento em segurança. Com o modelo certo, you can increase throughput, melhorar a higiene, and reduce operational costs.