1. Pengenalan kepada Mesin Pembuatan Tomato Tomato

A mesin pembuatan puree tomato adalah peranti perindustrian penting yang digunakan untuk menghancurkan, pemanasan, dan menapis tomato ke lancar, Bentuk separa cecair-biasanya dikenali sebagai puri tomato. Ia digunakan secara meluas di kilang pemprosesan makanan, dapur komersial, dan unit pembotolan permulaan untuk sos, Ketchups, dan produk kalengan.

2. Mengapa melabur dalam mesin pembuatan puri tomato?

Melabur dalam Mesin Puri Tomato menawarkan beberapa manfaat untuk perniagaan:

- Kecekapan tinggi: Proses beratus kilo sejam

- Menjimatkan kos: Mengurangkan kebergantungan pada buruh manual

- Output kebersihan: Memenuhi piawaian keselamatan makanan antarabangsa

- Penyesuaian: Ketebalan dan suhu laras

- Keuntungan: Puri mempunyai permintaan pasaran yang tinggi di sektor B2B dan B2C

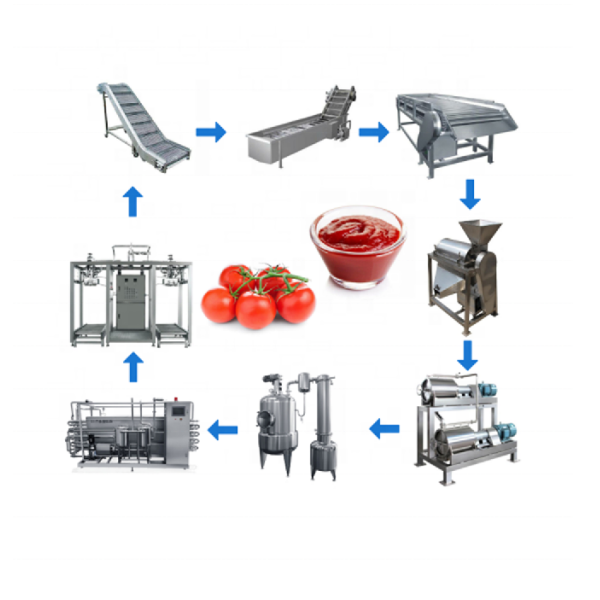

3. Prinsip Kerja Mesin Puri Tomato

Mesin membuat tomato tomato biasa berfungsi melalui prinsip berikut:

- Memberi makan: Tomato segar diberi makan melalui corong.

- Mencuci dan menyusun: Tomato dibersihkan dengan jet air bertekanan tinggi.

- Menghancurkan: Penghancur memecahkan tomato menjadi pulpa.

- Memanaskan: Pulpa dipanaskan untuk mengaktifkan enzim.

- Pulping dan penapisan: Benih dan kulit dipisahkan menggunakan penapis.

- Konsentrasi (pilihan): Kandungan air disejat untuk membuat puri yang lebih tebal.

- Pensterilan dan pengisian: Final Puree dipasteur dan dibungkus.

4. Komponen utama barisan pengeluaran puri tomato

| Komponen | Penerangan |

|---|---|

| Lif | Mengangkut tomato ke mesin basuh |

| Mesin basuh gelembung | Mengeluarkan kotoran dan kekotoran |

| Penghantar penyisihan | Menyusun berasaskan manual atau sensor |

| Penghancur | Memecahkan tomato menjadi pulpa |

| Preheater | Mengekalkan suhu penyahaktifan enzim |

| Pulper dan finisher | Menapis tekstur puri dan menghilangkan pepejal |

| Penyejat | Pilihan - mengurangkan kandungan air |

| Sterilizer | Membunuh bakteria dan patogen |

| Mesin pengisian | Pek puri ke dalam balang, kantung, atau tin |

5. Jenis Mesin Membuat Puri Tomato

a) Mesin Tomato Skala Kecil

Direka untuk pemula dan pemproses berasaskan rumah (10-50 kg/jam)

b) Unit berskala sederhana

Sesuai untuk dapur komuniti atau kilang kecil (100-500 kg/jam)

c) Garis perindustrian berskala besar

Sesuai untuk pengeluaran besar -besaran (1,000 kg/jam dan ke atas)

6. Jadual Spesifikasi Teknikal

| Model | Kapasiti | kuasa (kW) | Bahan | Jenis output | Dimensi |

|---|---|---|---|---|---|

| TPPM-50 | 50 kg/j | 2.2 kW | Mereka 304 Keluli tahan karat | Separa pasang | 1000× 600 × 900 mm |

| TPPM-100 | 100 kg/j | 3.5 kW | Mereka 304 | Halus | 1200× 700 × 1100 mm |

| TPPM-300 | 300 kg/j | 5.5 kW | Mereka 304 | Tertumpu | 1500× 900 × 1300 mm |

| TPPM-1000 | 1000 kg/j | 11 kW | Mereka 316 | Puree gred perindustrian | 2000× 1200 × 1500 mm |

7. Proses Pengeluaran Puree Tomato: Langkah demi langkah

- Pemilihan Tomato

- Mencuci dan membasmi kuman

- Mengupas dan menghancurkan

- Pemanasan

- Penapisan pulpa

- Konsentrasi

- Pensterilan

- Pembungkusan

8. Varieti tomato Sesuai untuk Puri

- Tomato Roma - Fleshy, biji yang lebih sedikit

- San Marzano - Manis dan rendah kelembapan

- Heinz 1370 - Sesuai untuk sos tomato dan puri

- Tomato plum -kos efektif dan tersedia secara meluas

9. Cara Memilih Mesin Puri Tomato yang Betul

Pertimbangkan kriteria ini:

- Kapasiti Berdasarkan jumlah harian anda

- Bahan (Mereka 304 vs 316) Bergantung pada rintangan asid

- Tahap automasi (manual, Semi-Auto, penuh-auto)

- Penggunaan elektrik dan air

- Sokongan selepas jualan

10. Aplikasi biasa puri tomato

- Sos pizza

- Paste asas

- Penyediaan kari

- Pengeluaran sos tomato

- Bahan makanan dalam tin

- Puri gred eksport di dalam kantung

11. Garis panduan pemasangan dan persediaan

- Keperluan ruang: Sekurang -kurangnya 20m² untuk garis kecil

- kuasa: 220V/380V tiga fasa

- Bekalan air: Saluran air bersih dengan penapisan

- Sistem saliran: Outlet efluen yang betul

- Latihan pengendali: Pengendalian dan keselamatan makanan asas

- Pengudaraan: Diperlukan di kawasan pemanasan

12. Analisis kos dan anggaran ROI

| Item | Kos (USD) |

|---|---|

| Mesin kecil (50 kg/jam) | $2,500 - $4,000 |

| Mesin sederhana (300 kg/jam) | $6,000 - $9,000 |

| Garis penuh (1,000 kg/jam) | $25,000 - $40,000 |

| Mesin pembungkusan | $3,000 - $8,000 |

| Buruh, utiliti (bulanan) | $1,000 - $3,000 |

Anggaran ROI:

- Tempoh bayaran balik: ~ 6-12 bulan

- Margin keuntungan setiap kg: $0.50- $ 1.50

- Break-Even Volume: ~ 5-10 tan

13. Petua Penyelenggaraan Mesin Tomato Puree

- Penapis bersih dan muncung setiap hari

- Pelincir bahagian bergerak setiap 2 minggu

- Sistem Pemanasan Descale Bulanan

- Ganti meterai getah setiap tahun

- Pemeriksaan elektrik suku tahunan

14. Cabaran dalam pengeluaran puri tomato

- Bermusim bahan mentah

- Keasidan tinggi → masalah kakisan

- Berbuih semasa preheating

- Risiko pencemaran semasa pembungkusan

- Pematuhan peraturan

15. Trend pasaran dan peluang perniagaan

- Meningkat Permintaan Global untuk Sauce Sedia-To-Cook

- Pertumbuhan jenama makanan label peribadi

- Peluang eksport di Timur Tengah dan Afrika

- Kelompok pemprosesan tomato muncul di India, Nigeria, Filipina

16. Penyelesaian Pembungkusan Tomato Puree

- Botol kaca - Penggunaan runcit

- Pek Tetra - Kehidupan jangka panjang

- Kantung berlapis - Ekonomi

- Tin logam - pukal dan eksport

17. Pematuhan peraturan dan kebersihan

- Ikuti Garis Panduan HACCP

- Memastikan FDA / CE / ISO peralatan yang disahkan

- Sanitize Sumber Water

- Mengekalkan log pembersihan harian

- Gunakan bahagian kenalan gred makanan (Mereka 304 atau lebih tinggi)

18. Soalan Lazim Mengenai Mesin Puri Tomato

Q1: Bolehkah saya menggunakan mesin untuk buah -buahan lain?

A: Ya. Beberapa mesin menyokong mangga, epal, atau cabai.

S2: Apakah Rak Kehidupan Puree?

A: 6-18 bulan berdasarkan pembungkusan dan pengawet.

Q3: Adakah pemasangan dimasukkan?

A: Beberapa pembekal menyediakan pemasangan dan latihan di seluruh dunia.

Q4: Bagaimana jika saya mahu menghasilkan saus tomat?

A: Anda boleh menambah tangki pencampuran dan perasa ke garisan.

19. Pembekal Global Teratas Mesin Puri Tomato

- DT Food Machine Co., Ltd. - mengetuai garis puree modular

- Pemprosesan Makanan Bertuzzi (Itali)

- Fenco (Itali)

- JBT Corporation (Amerika Syarikat)

20. Pemikiran dan Cadangan Akhir

Memulakan Perniagaan Tomato Puri dengan Jentera yang Betul adalah pelaburan pintar dalam ekonomi makanan yang semakin meningkat hari ini. Dengan perancangan pasaran yang betul, Sumber bahan mentah, dan peralatan berkualiti, Usahawan dapat mengubah tumbuh tomato menjadi produk yang menguntungkan.

Sama ada anda menubuhkan a unit pemprosesan kecil atau skala a garis puree tomato gred kilang, Pilihan mesin akan menentukan kejayaan anda. Untuk sokongan yang dijamin dan harga yang kompetitif, DT Food Machine Co., Ltd. adalah rakan kongsi yang dipercayai di seluruh dunia.