Cekap, tepat, dan pembungkusan pasta yang boleh dipercayai adalah salah satu langkah terpenting dalam rantaian pengeluaran pasta kering. A Mesin Pembungkusan Pasta memainkan peranan penting dalam kualiti produk, rayuan rak, dan keuntungan keseluruhan kilang. Sama ada pengilang berurusan dengan spageti, Macaroni, fusilli, penne, atau produk pasta bersaiz campuran, Sistem pembungkusan pasta yang direka dengan baik memastikan beratnya pantas, pengisian bersih, pengedap kuat, dan kehilangan produk yang minimum.

Panduan ini menyediakan struktur yang sama sekali baru dan dinaik taraf berbanding dengan versi terdahulu yang dianjurkan sebagai manual pembeli profesional. Ia meliputi komponen mesin utama, aliran kerja, teknologi, Kata kunci ekor panjang, dan nasihat pemilihan praktikal untuk pemproses makanan, pengedar, dan kilang pasta.

1. Apa itu mesin pembungkusan pasta? (Gambaran keseluruhan asas)

A Mesin Pembungkusan Pasta adalah peralatan khusus yang direka untuk menimbang, mengisi, membentuk, dan menyegel pasta kering ke dalam beg atau kantung. Ia menggabungkan:

- Sistem Penimbang Pasta Automatik

- Unit pembentukan beg

- Mengisi dispenser

- Mekanisme pengedap haba

- Modul pengekodan dan pelabelan

Moden garisan pembungkusan pasta automatik boleh disatukan dengan peralatan pengeringan hulu, penghantar, lif, Pemeriksa, dan pengesan logam untuk membuat berterusan, sistem pembungkusan automatik sepenuhnya.

Variasi panjang ekor biasa:

- Mesin Pembungkusan Spaghetti

- Peralatan pembungkusan makaroni

- Mesin Bagging Pasta Automatik

- Pasta menimbang dan mengisi sistem

- peralatan pengedap kantung pasta

- garis pembungkusan pasta kering

- Mesin pembungkusan pasta vffs (Bentuk menegak mengisi meterai)

2. Mengapa kilang pasta moden memerlukan penyelesaian pembungkusan pasta automatik

2.1 Kadar ralat berat dan rendah yang konsisten

Pembungkusan manual sering membawa kepada berat badan yang tidak tepat, yang meningkatkan kerugian hadiah.

Penggunaan Mesin Lanjutan Weighers Multi-Head dengan ketepatan ketepatan yang tepat sehingga ± 0.2 g.

2.2 Kelajuan pengeluaran yang lebih cepat

Barisan pembungkusan automatik boleh dicapai:

- 30-70 beg/min (Mesin Pembungkusan Pasta Mid-Range)

- Hingga 120 beg/min (penyelesaian pembungkusan pasta berkelajuan tinggi)

Kecekapan ini menjadikan mereka sesuai untuk pengeksport dan pengeluar pasta berskala besar.

2.3 Struktur gred makanan yang bersih

Mesin digunakan:

- Keluli tahan karat 304/316

- Tiub pembentukan tertutup

- Reka bentuk kawalan habuk

- Bahagian kenalan gred makanan

Ini memastikan pematuhan FDA, CE, ISO, HACCP, dan standard keselamatan makanan lain.

2.4 Kos buruh yang lebih rendah dan risiko operasi

Satu pengendali dapat menguruskan keseluruhan garis pembungkusan pasta automatik, mengurangkan kesilapan manusia dan risiko pencemaran.

3. Jenis Mesin Pembungkusan Pasta (Diklasifikasikan untuk kilang yang berbeza)

Berikut adalah format klasifikasi yang sama sekali berbeza berbanding dengan artikel lama-lebih berorientasikan kejuruteraan dan praktikal.

3.1 Bentuk menegak mengisi meterai (VFFS) Mesin Pembungkusan Pasta

The Bentuk menegak mengisi mesin pasta meterai adalah penyelesaian yang paling popular untuk pembungkusan pasta kering dalam beg bantal atau kantung gusset.

Ciri -ciri:

- Filem automatik menarik dan membentuk

- Ketepatan berat sebelum mengisi

- Pengedap haba cepat

- Bekerja dengan OPP/CPP, Haiwan kesayangan/pe, Filem lamina aluminium

Sesuai untuk:

- Spaghetti

- Penne

- Fusilli

- Pasta patah

- Bentuk pasta campuran

Kata kunci ekor panjang termasuk: Pek pasta VFFS, mesin pembungkusan menegak pasta, Sistem pasta FFS

3.2 Mesin Pembungkusan Pasta Pouch Premade

Direka untuk beg zip, Doypacks, dan kantung berdiri.

Kelebihan:

- Lebih banyak penampilan premium

- Sesuai untuk format pembungkusan yang fleksibel

- Pilihan zip reclosable

Kes penggunaan biasa:

- Jenama pasta runcit

- Pengeksport pasta premium

- Kilang pasta kecil dan pertengahan

3.3 Pasta separa automatik yang menimbang dan mesin pembungkus

Sistem hibrid menggabungkan penempatan beg manual dengan berat dan pengedap automatik.

Disyorkan untuk:

- Permulaan

- Kilang-kilang volum rendah

- Bengkel pasta kecil

Contoh panjang ekor: Mesin Bagging Pasta Separa Automatik, Mesin Pembungkusan Pasta Belanjawan

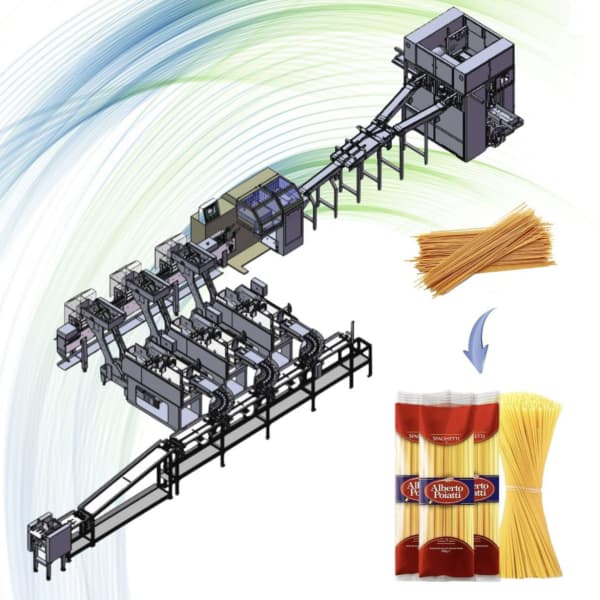

3.4 Garis pembungkusan pasta automatik sepenuhnya dengan integrasi penghantar

Ini adalah penyelesaian yang paling maju dan merangkumi:

- Lif Bucket Z-Type

- Pasta Multi-Head lebih berat

- Unit pembentukan menegak

- Penghantar produk siap

- Pengesan logam (pilihan)

- Checkweigher (pilihan)

- Sistem pembungkusan kadbod automatik (pilihan)

Kata kunci dilindungi: garis pembungkusan pasta automatik sepenuhnya, automasi pembungkusan pasta kering, pasta pengisian dan pengedap pasta

4. Struktur teknikal mesin pembungkusan pasta (Penjelasan peringkat kejuruteraan)

Berikut adalah kerosakan profesional yang sesuai untuk pembeli, jurutera, dan jabatan perolehan.

4.1 Sistem seberat pelbagai kepala

- Feeder bergetar

- Dulang pemakanan linear

- Sel beban

- Unit pemprosesan pusat

- Mekanisme corong drop

Memastikan ketepatan dan mengurangkan kepingan pasta yang rosak.

4.2 Sistem pembentukan beg

- Bekas bahu filem

- Tiub membentuk menegak

- Sistem lipatan tepi

- Struktur pengedap bawah

4.3 Mekanisme pengisian

Bergantung pada jenis pasta, mesin menggunakan:

- Gravity Drop Chute

- Pengumpan putar untuk pasta rapuh

- Makan Makan untuk Pasta Panjang

4.4 Mekanisme pengedap

Pasta kering memerlukan kuat, Pengedap Hermetik:

- Pembalut menegak

- Pembalut mendatar

- Pilihan nitrogen flushing

- Kawalan suhu automatik

Beg yang dipenuhi nitrogen memanjangkan hayat rak dan mencegah kelembapan.

4.5 Sistem kawalan (Plc + Panel sentuh HMI)

- Tetapan parameter visual

- Diagnostik ralat

- Paparan data pengeluaran

- Filem Roll Auto-Alignment

Serasi dengan Siemens, Omron, Schneider, atau sistem delta.

5. Alur kerja mesin pembungkusan pasta (Langkah demi langkah)

- Makan pasta melalui penghantar

- Berat automatik

- Filem menarik dan membentuk beg

- Mengisi pasta kering ke dalam beg

- Pengedap haba

- Pengekodan dan percetakan

- Output beg

- Pemeriksaan berkualiti

- Pembungkusan kadbod (pilihan)

- Palletizing (pilihan)

6. Format pembungkusan Mesin pembungkusan pasta dapat mengendalikan

- Beg bantal

- Gusset Bag

- Beg bawah blok

- Pouch berdiri

- Pouch Zipper

- Beg vakum (pilihan)

- Beg telus PE

- Kantung filem OPP berlamina

7. Aplikasi yang ideal dan pengguna sasaran

Bahagian ini menggunakan format berasaskan senario untuk berbeza dari artikel sebelumnya.

Senario 1: Pengilang pasta berorientasikan eksport

Keperluan:

- 100-120 beg/min

- Pengedap kuat

- Automasi Karton

Penyelesaian: Barisan pembungkusan pasta berkelajuan tinggi automatik sepenuhnya

Senario 2: Jenama pasta label peribadi pasar raya

Keperluan:

- Premium Stand-Up Pouch

- Pembungkusan zip

- Reka bentuk yang menarik

Penyelesaian: Sistem Pengisian Pasta Premade Pouch

Senario 3: Kilang Pasta Tempatan atau Pengeluar Artisan

Keperluan:

- Mesra bajet

- Jejak kecil

- Jumlah pengeluaran yang lebih rendah

Penyelesaian: Mesin Bagging Pasta Separa Automatik

8. Parameter teknikal utama (Jadual Rujukan Am)

| Item | Spesifikasi biasa |

|---|---|

| Kelajuan pembungkusan | 30-120 beg/min |

| Ketepatan berat | ± 0.2-1.0 g |

| Lebar beg | 80-250 mm |

| Panjang beg | 120-400 mm |

| Ketebalan filem | 40-100 μm |

| kuasa | 2.5-4.5 kW |

| Voltan | 220V/380V Pilihan |

| Bahan pembungkusan | Naik/pe, Haiwan kesayangan/al/pe, Filem berlamina |

9. Cara Memilih Mesin Pembungkusan Pasta Terbaik (Panduan Pembeli)

9.1 Tentukan jenis pasta

- Spaghetti → memerlukan format beg panjang

- Penne / Fusilli → Memerlukan Multi-Head Weigher

- Pasta patah kecil → memerlukan reka bentuk anti-dust

9.2 Pilih format pembungkusan

- Beg Bantal → VFFS

- Pouch Stand-Up → Premade Pouch Mesin

- Beg Zipper → Peralatan Pembungkusan Pouch

9.3 Pertimbangkan jumlah pengeluaran

- Output kecil → separa automatik

- Sederhana → Mesin Pembungkusan Pasta Menegak Standard

- Perindustrian → Barisan Pembungkusan Pasta Bersepadu sepenuhnya

9.4 Pertimbangkan pengembangan masa depan

Pilih reka bentuk modular dengan antara muka untuk:

- Pengesan logam

- Cartoners

- Nitrogen Flushing

- Pemeriksa

10. Soalan yang sering ditanya (Liputan kata kunci panjang lengkap)

Q1: Apakah mesin terbaik untuk pembungkusan spageti?

A Mesin Pembungkusan Spaghetti dengan tiub pembentukan panjang dan sistem pemakanan manual atau auto sangat sesuai.

S2: Bolehkah mesin pek mesin yang berbeza?

Ya. Pengendalian pelbagai kepala Macaroni, penne, fusilli, Rigatoni, Kerang, dan pasta patah.

Q3: Filem apa yang paling sesuai dengan mesin pemangkas pasta?

Sebilangan besar kilang pasta menggunakan filem OPP/CPP atau PE/PE berlapis berlapis.

Q4: Cara Mencegah Kerosakan Pasta Semasa Pembungkusan?

Gunakan Feeder Gravity Gentle dan ketinggian drop yang dioptimumkan.

S5: Bolehkah saya menambah nitrogen siram?

Ya -Banyak Mesin pengedap pasta Pembungkusan peta sokongan.

S6: Berapa banyak pengendali yang diperlukan?

Barisan pembungkusan pasta automatik sepenuhnya memerlukan satu pengendali.

11. Kesimpulan - Mengapa melabur dalam mesin pembungkusan pasta moden?

Prestasi tinggi Mesin Pembungkusan Pasta meningkatkan kelajuan, mengurangkan kos buruh, meningkatkan keselamatan makanan, dan menguatkan daya saing mana -mana jenama pasta. Sama ada anda memerlukan penyelesaian pembungkusan pasta separa automatik yang padat atau garis pembungkusan pasta perindustrian yang lengkap, Peralatan automatik moden menjamin hasil yang konsisten dan keuntungan jangka panjang.