1. Pengenalan: Apakah barisan pengeluaran mi segera dengan mesin pembungkusan ?

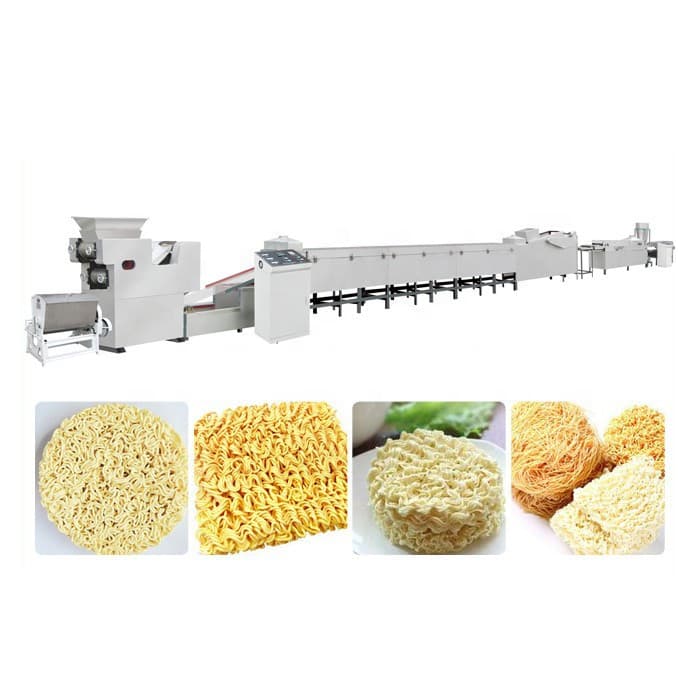

An Barisan pengeluaran mi segera dengan mesin pembungkusan Adakah automatik sepenuhnya, Sistem skala industri yang direka untuk menghasilkan, Masak, kering, dan pakej mi segera dengan cekap dan kebersihan. Barisan pengeluaran ini penting bagi pengeluar yang ingin memenuhi permintaan global yang semakin meningkat sambil mengekalkan konsistensi produk, keselamatan, dan kestabilan rak.

Garis lengkap ini termasuk peringkat untuk pencampuran doh, mengukus, pemotongan mi dan membentuk, menggoreng atau mengeringkan udara, penyejukan, dan pembungkusan automatik bersepadu.

2. Permintaan global dan trend pasaran

Pasaran mi segera telah menyaksikan pertumbuhan eksponen di seluruh Asia, Afrika, Amerika Latin, dan Eropah Timur. Menurut World Instan Association (Yang lain), lebih daripada 120 bilion hidangan dimakan secara global setiap tahun.

Trend utama:

- Pertumbuhan dalam mi cawan dan mi bukan goreng

- Peningkatan permintaan untuk pembungkusan automatik

- Pengembangan ke mi bebas yang lebih sihat dan gluten

- Integrasi dengan Kawalan kualiti yang didorong oleh AI

3. Jenis mi segera

Barisan pengeluaran anda boleh disesuaikan untuk menghasilkan pelbagai jenis mi:

- Mi segera goreng (paling biasa)

- Mi kukus dan kering (Pilihan yang lebih sihat)

- Mi cawan (pra-pakej dalam mangkuk atau cawan)

- Mi mi (Blok longgar dalam kerajang/kertas/plastik)

Setiap jenis mi memerlukan sedikit perubahan dalam komponen pemprosesan dan pembungkusan.

4. Gambaran keseluruhan proses pengeluaran

Aliran kerja pengeluaran mi segera biasanya mengikuti langkah -langkah ini:

- Bahan pencampuran (tepung, air, garam, aditif)

- Pelepasan doh dan pengkompaunan

- Mengukus lembaran mi

- Memotong dan membentuk helai mi

- Menggoreng atau mengeringkan

- Penyejukan dan penjajaran

- Berat dan pembungkusan dengan sachet perasa

- Pengedap dan pelabelan

- Tinju kadbod dan palletizing

5. Komponen teras barisan pengeluaran mi segera

| Nama komponen | Fungsi |

|---|---|

| Pengadun Doh | Bentuk adunan seragam dari bahan |

| Roller kompaun | Lembaran dan adunan padat |

| Penghantar mengukus | Mengukus mi untuk memasak mereka di tengah hari |

| Peranti pemotongan | Memotong mi menjadi helai halus |

| Penggoreng atau pengering | Membuang kelembapan, Meningkatkan kehidupan rak |

| Penghantar Penyejuk | Menurunkan suhu sebelum pembungkusan |

| Feeder perasa | Dispenses sachets perasa |

| Mesin pembungkusan automatik | Bungkus dan anjing laut |

| Pengesan logam | Memastikan pematuhan keselamatan makanan |

| Pengekodan & Sistem pelabelan | Mencetak nombor tamat tempoh dan batch |

6. Kerosakan terperinci: Dari adunan hingga pembungkusan akhir

6.1 Penyediaan doh dan pencampuran

Pengadun vakum berkelajuan tinggi menggabungkan tepung gandum, Air Alkali, dan nutrien pilihan di bawah tekanan terkawal, membentuk adunan elastik.

6.2 Lembaran dan rolling

Pelbagai penggelek memampatkan doh ke dalam lembaran dengan ketebalan laras.

6.3 Seksyen pengukus

Mengukus kanji gelatinizes, membentuk tekstur mi yang dikehendaki. Suhu ~ 100 ° C..

6.4 Pemotongan dan keriting

Lembaran kukus dipotong menjadi helai dan bergulung ke dalam bentuk bergelombang ciri menggunakan pisau berputar.

6.5 Penggoreng atau pengeringan udara panas

Goreng minyak sawit pada ~ 150-160 ° C selama 90-120 saat, atau kering udara untuk produk yang sedar kesihatan.

6.6 Zon penyejuk

Disejukkan udara ke suhu ambien untuk mengelakkan pemeluwapan dalam pembungkusan tertutup.

6.7 Penyisipan berat dan sachet

Setiap blok mi dipasangkan dengan serbuk rasa, Sachet minyak, atau sayur -sayuran dehidrasi.

6.8 Sistem pembungkusan automatik

Mi dan sachet dibungkus dalam cawan atau dibalut aliran menggunakan FFS mendatar atau menegak maju (Form-fill-seal) sistem.

7. Jenis mesin pembungkusan untuk mi segera

7.1 Mesin bungkus aliran mendatar

- Sesuai untuk pek plastik jenis bantal

- Kelajuan: 100-300 pek/minit

7.2 Mesin pembungkusan mi cawan/mangkuk

- Mengendalikan bekas dengan penutup

- Bersepadu dengan pengedap dan pelabelan

7.3 Mesin FFS menegak

- Hebat untuk sachet perasa

- Beg Bentuk, mengisi, dan anjing laut secara automatik

7.4 Mesin karton dan bundling

- Kumpulan berkemas ke dalam kotak runcit

- Pilihan mengecut-pembungkus yang tersedia

8. Pertimbangan Bahan Pembungkusan dan Rak Kehidupan

| Jenis Bahan | Penerangan | Faedah |

|---|---|---|

| Filem bopp/pp | Biasa untuk mi yang dibangkitkan | Kos rendah, halangan kelembapan |

| Cawan kertas + Tudung Foil | Digunakan untuk mi cawan | Microwave selamat, Stackable |

| Kantung berbilang lapisan | Untuk paket perasa | Penghalang yang tinggi, Memelihara aroma |

Kehidupan rak biasanya berkisar 6 bulan ke 12 bulan, bergantung pada kandungan minyak dan bahan pembungkusan.

9. Spesifikasi teknikal barisan pengeluaran

Jadual berikut membentangkan terperinci Spesifikasi Teknikal Untuk purata barisan pengeluaran mi segera berskala perindustrian dengan mesin pembungkusan:

| Spesifikasi | Nilai/julat |

|---|---|

| Kapasiti pengeluaran | 30,000 - 300,000 pek/hari |

| Kelajuan output | 80-300 kek mi/min |

| Jilid pencampuran doh | 50-500 kg/batch |

| Suhu mengukus | 98-105 ° C. |

| Menggoreng suhu minyak (Mi goreng) | 150-165 ° C. |

| Pengeringan temp (Mi bukan goreng) | 75-95 ° C. |

| Kelajuan mesin pembungkusan | 80-200 pek/min |

| Bekalan kuasa | 380V / 50Hz / 3 Fasa |

| Jumlah penggunaan kuasa | 100-250 kW (Bergantung pada skala) |

| Bahan mesin | Keluli tahan karat SUS304 gred makanan |

| Tekanan udara (untuk pembungkusan) | 0.6-0.8 MPa |

| Penggunaan air | 2-4 m³/jam |

| Panjang garis | 20M -70m (berdasarkan kapasiti & susun atur) |

Semua bahagian bersentuhan dengan makanan FDA, CE, dan ISO 22000 piawaian.

10. Susun atur dan perancangan ruang

Perancangan susun atur kilang yang betul membantu memastikan kecekapan aliran kerja, keselamatan makanan, dan kemudahan pembersihan. Garis mi segera berskala sederhana (Mis., 150,000 pek/hari) biasanya memerlukan:

- Kawasan kilang: 800-1,500 m²

- Zon:

- Penerimaan bahan mentah & penyimpanan

- Doh pemprosesan dan kawasan pengukus

- Bahagian pengeringan atau penggoreng

- Penyejukan & zon pembungkusan

- Pembungkusan akhir & penghantaran

- Pertimbangan:

- Aliran linear dari produk mentah hingga siap

- Kemasukan/keluar berasingan untuk bahan mentah dan kakitangan

- Sistem saliran untuk cip mudah (Bersih di tempat)

- Kelembapan terkawal di kawasan pengeringan

11. Keperluan tenaga dan utiliti

Anggaran tenaga dan utiliti yang betul adalah penting untuk belanjawan dan kejuruteraan tumbuhan.

| Sumber | Anggaran penggunaan (Per 1000 kg) |

|---|---|

| Elektrik | 150-250 kWh |

| Wap | 300-500 kg |

| Air | 2-4 m³ |

| Udara termampat | 5-10 m³/jam |

| Minyak menggoreng (jika digunakan) | 0.8-1.2 kg per kg blok mi |

Anda boleh mengoptimumkan penggunaan menggunakan:

- Sistem pemulihan haba

- Pembakar kecekapan tinggi

- Motor yang dikawal oleh VFD

- Pemanaskan solar

12. Sistem automasi dan kawalan

Barisan mi segera moden sangat automatik, Mengintegrasikan sistem kawalan PLC dan HMI untuk memastikan konsistensi dan pemantauan:

Ciri-ciri Utama:

- Panel kawalan skrin sentuh (HMI)

- Integrasi SCADA Untuk analisis masa nyata

- Sistem Pengurusan Resipi

- Diagnostik Jauh IoT

- Sensor untuk tekanan, suhu, kelajuan

- Penggera automatik dan pengesanan kesalahan

Pengendali boleh beralih antara produk, Laraskan parameter, atau memantau makluman penyelenggaraan terus dari skrin.

13. Kapasiti dan skalabiliti barisan pengeluaran

Barisan pengeluaran boleh didapati dalam pelbagai konfigurasi yang sesuai dengan setiap saiz perniagaan:

| Skala Pengeluaran | Kapasiti output (Pek/hari) | Sesuai untuk |

|---|---|---|

| Skala kecil | 20,000-50,000 | Kedai mi tempatan, PKS |

| Skala sederhana | 80,000-150,000 | Pengilang makanan serantau |

| Skala besar | 200,000-300,000+ | Pengeksport, Jenama Global |

Talian boleh ditingkatkan oleh:

- Menambah lebih banyak terowong pengeringan/menggoreng

- Menaik taraf ke unit pembungkusan berbilang kepala

- Memasang lengan pick-and-place robot

14. Prosedur penyelenggaraan dan pembersihan

Penyelenggaraan yang betul memastikan umur panjang, Kebersihan, dan prestasi.

Tugas harian:

- Bersih extruder mati dan ruang mengukus

- Tiriskan dan menapis minyak goreng (jika berkenaan)

- Sanitisasi pisau pemotongan dan tali pinggang penghantar

Tugas mingguan:

- CIP: Paip bersih di tempat, garisan wap

- Perubahan minyak dalam kotak gear, Motor Grasing

- Penapis udara dan pembersihan penapis air

Tugas bulanan:

- Menentukur sensor dan sistem PLC

- Ganti tali pinggang atau lembaran Teflon yang haus

Gunakan detergen makanan yang selamat dan Salutan anti-mikrob untuk mengelakkan pencemaran.

15. Perakuan Keselamatan dan Pematuhan Makanan

Barisan pengeluaran mi segera anda mesti mematuhi piawaian berikut:

| Pensijilan | Penerangan |

|---|---|

| CE | Pematuhan Keselamatan dan Jentera Eropah |

| ISO 22000 / HACCP | Sistem Pengurusan Keselamatan Makanan |

| FDA / Lfgb | Keselamatan bahan untuk permukaan makanan |

| GMP | Amalan pembuatan yang baik |

| Laporan SGS/BV | Pengesahan peralatan dan kebersihan bebas |

Pengilang perlu membekalkan dokumentasi penuh termasuk:

- Skema elektrik

- Manual Pengguna dan Pembersihan

- Jadual Penyelenggaraan

- Senarai alat ganti

16. Pengeluar utama dan pembekal global

Semasa memilih pembekal, pertimbangkan:

- Pengalaman dan reputasi

- Ketersediaan alat ganti

- Latihan dan sokongan

- Keupayaan penyesuaian

Pembekal global teratas:

- Kejuruteraan Nissin (Jepun)

- Kumpulan Bühler (Switzerland)

- Kumpulan Pavan / Gea (Itali)

- DT Food Machine Co., Ltd. (China)

- Jentera Makanan Anko (Taiwan)

- Sistem Makanan Unitherm (Amerika Syarikat)

17. Kos Pelaburan dan Analisis ROI

Pelaburan bergantung pada skala output, tahap automasi, dan konfigurasi.

| Jenis baris | Anggaran kos (USD) |

|---|---|

| Skala kecil | $50,000- $ 100,000 |

| Skala sederhana | $150,000- $ 300,000 |

| Skala besar | $400,000- $ 800,000+ |

Faktor ROI:

- Permintaan pasaran tempatan

- Margin keuntungan setiap pek

- Penjimatan kos buruh

- Kos pembungkusan seunit

Kebanyakan kilang Mendapatkan pelaburan dalam masa 12-24 bulan.

18. Kajian kes dan aplikasi perindustrian

Kajian kes 1: Vietnam - garis skala sederhana

- Output: 120,000 pek/hari

- Pembungkusan: Pek bantal dengan selimut tiga

- ROI: 16 bulan

Kajian kes 2: Kenya-Talian Bukan Goreng

- Output: 30,000 mi cawan/hari

- Dikuasakan oleh sistem pemanasan solar

- ROI: 22 bulan

Kajian kes 3: Mexico-Talian eksport berskala besar

- Output: 300,000 pek/hari

- Integrasi SCADA sepenuhnya automatik

- Eksport ke Amerika Syarikat dan Kanada

19. Masalah biasa dan penyelesaian masalah

| Isu | Sebab | Penyelesaian |

|---|---|---|

| Helai mi patah | Pemotong yang berlebihan atau membosankan | Laraskan ketegangan kepingan, ganti bilah |

| Degradasi minyak | Digunakan semula terlalu banyak kitaran | Gunakan sensor automatik atau sensor minyak |

| Pembungkusan misalignment | Kegagalan masa atau sensor | Sensor semula dan penyegerakan penghantar |

| Mi melekat dalam penggoreng | Gelatinisasi kanji yang tidak betul | Mendaftar semula suhu mengukus |

20. RFQ - Soalan Lazim

Q1: Bolehkah saya menyesuaikan bentuk dan saiz kek mi?

Ya. Anda boleh menyesuaikan acuan, Plat mati, dan saiz pemotong.

S2: Apakah perbezaan antara mi goreng dan bukan goreng dalam jentera?

Mi goreng memerlukan penggoreng, Penapis Minyak, dan tudung ekzos; mi bukan goreng Gunakan terowong kering udara yang lebih lama dan pengoptimuman stim.

Q3: Berapa lama pemasangan mengambil?

Biasanya 30-60 hari, termasuk latihan.

Q4: Bolehkah satu baris menghasilkan kedua -dua cawan dan pek bantal?

Ya, dengan modul pembungkusan yang boleh ditukar ganti.

S5: Adakah bahasa tempatan disokong dalam sistem kawalan?

Ya, Panel HMI boleh diprogramkan pelbagai bahasa.

S6: Bolehkah perasa dimasukkan secara automatik?

Ya. Dispenser sachet Mengendalikan pelbagai paket setiap pek.

Q7: Berapakah kadar penggunaan minyak?

Kira -kira 0.8-1.2 kg minyak per kg mi Untuk jenis goreng.

Q8: Adakah mudah untuk menukar produk atau saiz?

Ya. Kebanyakan baris membenarkan Perubahan bebas alat Dalam 30-60 minit.

Q9: Apa jenis buruh yang diperlukan?

Garis 150,000 Pek/hari mungkin perlu 6-10 pengendali per shift.

Q10: Apa sokongan penyelenggaraan yang ada?

Tawaran pengeluar Diagnostik Jauh, alat ganti, dan Lawatan di tapak.

21. Inovasi masa depan dalam pemprosesan mi segera

- Kamera pemeriksaan berkuasa AI untuk mengesan kecacatan dalam masa nyata

- Penggerak pintar dengan pengurusan minyak adaptif

- Bahan pembungkusan mesra alam Seperti filem biodegradable

- Sistem plug-and-play modular untuk pengembangan yang cepat

- Lengan robot untuk kadbod dan palletizing

- Sambungan IoT untuk penyelenggaraan ramalan

22. Kesimpulan: Mengapa melabur selaras dengan pembungkusan bersepadu?

Bersepadu sepenuhnya barisan pengeluaran mi segera dengan mesin pembungkusan tawaran:

- Produktiviti dan margin keuntungan yang lebih tinggi

- Dikurangkan buruh manual dan kesilapan manusia

- Keselamatan makanan dan kebolehkesanan makanan yang lebih baik

- ROI yang lebih cepat dengan operasi berskala

- Kelebihan daya saing di pasaran domestik dan eksport

Sama ada anda permulaan atau jenama makanan global, Pelaburan ini adalah tulang belakang kejayaan dalam industri mi segera hari ini.