1. Pengenalan

Instant noodles are one of the most popular fast foods across the globe, with billions of servings consumed annually. Behind this massive consumption is a complex, berkapasiti tinggi, and precise system — the instant noodle making machine. This machine automates the entire process, from dough mixing to steaming, memotong, menggoreng atau mengeringkan, dan pembungkusan, total named Barisan pengeluaran mi segera.

2. What Is an Instant Noodle Making Machine?

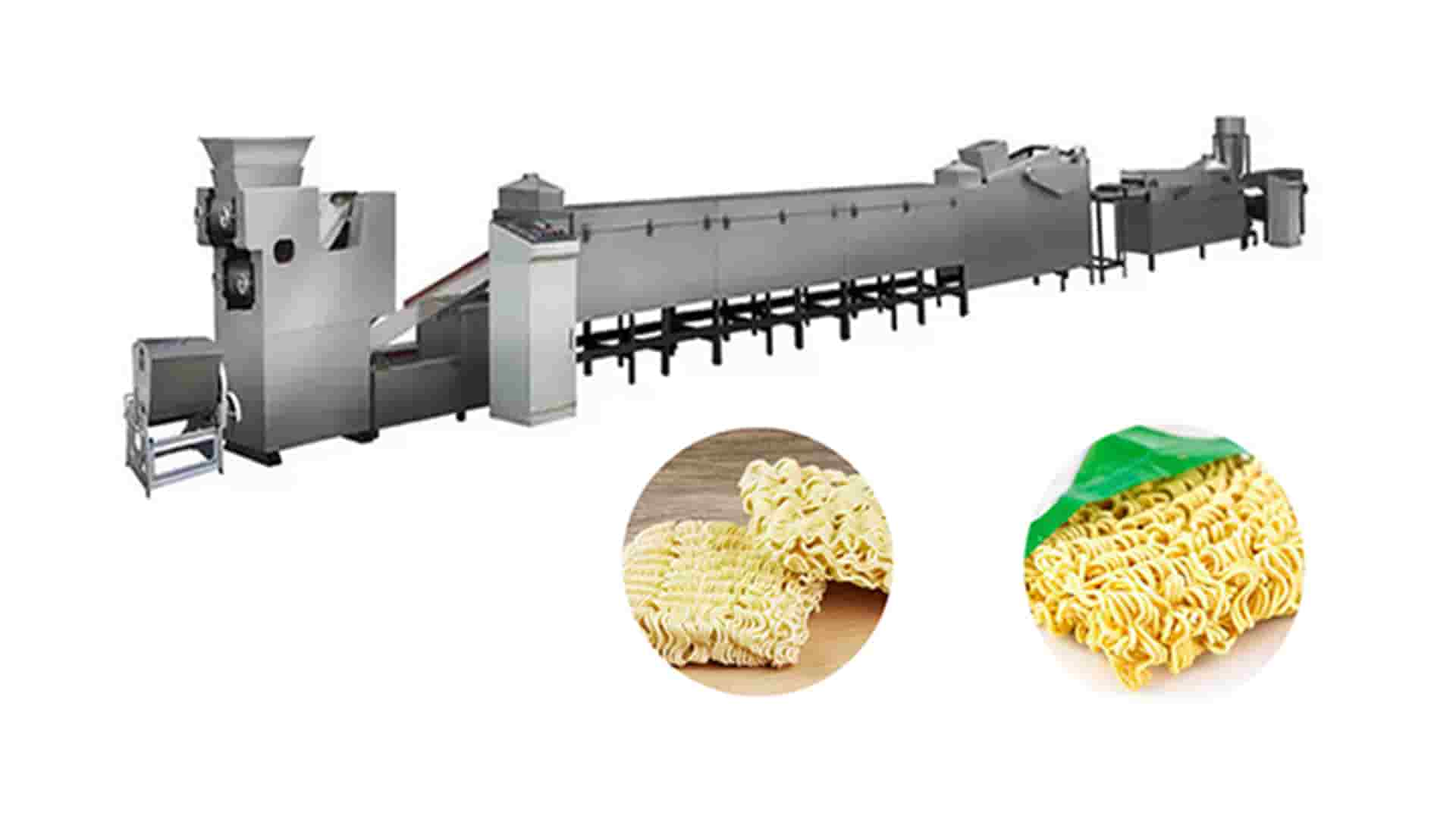

An instant noodle making machine is an industrial food processing machine used to manufacture noodles that are pre-cooked and dried so that they can be rehydrated easily in boiling water. These machines are designed to handle bulk production while ensuring consistency in texture, rasa, dan kualiti.

Ciri -ciri:

- Fully automatic processing

- Continuous production line

- Customizable sizes and shapes of noodles

- Compatible with oil-frying or hot-air drying processes

- Low human labor requirement

3. Types of Instant Noodle Making Machines

There are two major types of instant noodle making machines, each designed for specific production goals:

3.1 Fried Instant Noodle Machine

- Produces oil-fried instant noodles.

- Includes an oil-frying tunnel.

- Gives the noodles a crisp texture and longer shelf life.

3.2 Non-fried (Hot Air-Dried) Mesin mi segera

- Uses hot air drying instead of oil frying.

- Healthier alternative.

- Usually costs more due to drying tunnel and energy consumption.

4. Key Components and Their Functions

| Komponen | Penerangan |

|---|---|

| Pengadun Doh | Mixes flour, air, and additives into dough. |

| Compound Rolling Machine | Presses the dough into thin sheets. |

| Continuous Rolling System | Gradually flattens the dough to the desired thickness. |

| Slitter & Pemotong | Cuts the sheet into noodle strands. |

| Steam Tunnel | Cooks the noodles using high-pressure steam. |

| Shaper | Shapes noodles into blocks. |

| Frying or Drying Tunnel | Cooks the noodles (menggoreng) or dries them (pengeringan udara). |

| Penghantar Penyejuk | Cools down the noodles before packaging. |

| Unit pembungkusan | Automates the packing process. |

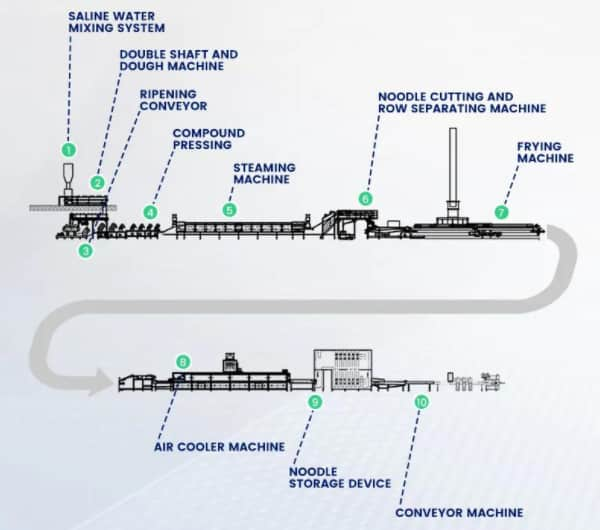

5. Working Principle of an Instant Noodle Production Line

- Mixing Stage: Flour and water are mixed to create a uniform dough.

- Lembaran: Dough is compressed into sheets via rollers.

- Slitting: The dough sheet is cut into thin noodle strips.

- Mengukus: Noodle strips pass through a steam tunnel to precook them.

- Membentuk: Noodles are folded or molded into blocks.

- Memasak: Blocks are either fried in oil or dried using hot air.

- Penyejukan: The noodle blocks are cooled on conveyors.

- Pembungkusan: Finished noodle blocks are wrapped and sealed.

6. Technical Parameters and Specifications

| Parameter | Spesifikasi |

|---|---|

| Kapasiti | 20,000 kepada 300,000 packs/8h |

| Bekalan kuasa | 380V, 50Hz / boleh disesuaikan |

| Jumlah penggunaan kuasa | 60 KW - 180 kW depending on size |

| Floor Space Requirement | 60–300 m² |

| Operator Needed | 3–5 people |

| Bahan | Keluli tahan karat (Gred makanan 304) |

| Suhu menggoreng | 140–160°C |

| Suhu pengeringan (Udara panas) | 80–110°C |

| Noodle Size | Boleh disesuaikan: 40g–100g blocks |

| Tahap automasi | Full-automatic / Separa automatik |

7. Panduan Pemasangan

7.1 Site Preparation

- Ensure concrete flooring with drainage.

- Provide 3-phase electrical wiring.

- Water inlet and outlet pipelines must be installed.

- Allocate sufficient space for machine layout.

7.2 Langkah pemasangan

- Unpack all modules and place according to layout plan.

- Connect electric circuits and water supply.

- Assemble conveyors, steam tunnels, and frying/drying systems.

- Semak semua bolt, pendawaian, and motors before starting.

- Run empty trial to confirm functionality.

7.3 Keperluan Keselamatan

- Ground the equipment properly.

- Ensure no water spillage near electric panels.

- Equip the area with fire extinguishers.

8. Arahan operasi

- Panaskan the system (fryer/dryer and steam tunnel).

- Load ingredients into the mixer (tepung + air + aditif).

- Start rolling, slitting, mengukus, membentuk, and frying/drying sequentially.

- Observe the quality of output and adjust speed/temperature.

- Switch on packaging unit to pack finished products.

- Shutdown procedure: turn off heating, run cool-down conveyor, power off.

9. Petua Penyelenggaraan dan Pembersihan

- Setiap hari: Clean flour residue, oil tanks, and conveyors.

- Mingguan: Pelincir bahagian bergerak; check steam pipes for blockages.

- Bulanan: Inspect motors and sensors; clean fryer/dryer thoroughly.

- Annually: Menentukur sensor suhu; replace worn belts and blades.

10. Common Troubleshooting Issues

| Masalah | Penyelesaian |

|---|---|

| Dough too dry/wet | Adjust water-flour ratio |

| Noodle breaks during cutting | Check cutter sharpness and speed |

| Uneven cooking | Check steam tunnel for blockages |

| Oil foaming in fryer | Replace old oil, maintain correct temperature |

| Packaging error | Inspect sealing unit or alignment |

11. Choosing the Right Instant Noodle Machine for Your Factory

Selecting the right instant noodle making machine depends on various factors including production goals, belanjawan, available space, and the target market. Here’s a comprehensive guide to help you choose the best fit:

11.1 Define Your Production Needs

- Kapasiti: Estimate the number of noodle blocks per hour/day.

- Fried vs. Non-fried: Decide whether you want to produce traditional fried noodles or healthier air-dried versions.

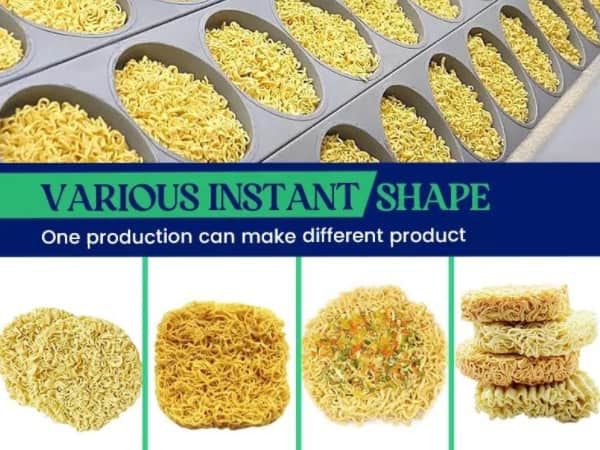

- Penyesuaian: Will you produce various flavors, saiz, or noodle shapes?

11.2 Evaluate Machine Types

| Jenis mesin | Sesuai untuk | Nota |

|---|---|---|

| Fully-Automatic Line | Large factories with high volume | Less labor-intensive |

| Semi-Automatic Line | Mid-sized enterprises | Requires some manual labor |

| Compact Line | Startups and R&D units | Lower output but space-saving |

11.3 Sokongan Pengilang

- Does the manufacturer provide on-site installation and training?

- Is there a warranty and post-sales support?

- Can they customize the machine layout?

Petua: Consider working with a reliable food machinery supplier like Mesin Makanan DT, known for turnkey instant noodle production lines.

12. Applications and End-Products

Instant noodle machines are versatile and can be used to produce various noodle types and packaging styles:

12.1 Jenis mi segera

- Classic curly fried noodles (block shape)

- Straight air-dried noodles (Japanese-style)

- Mi cawan

- Rice noodles or gluten-free variants (with modification)

12.2 Market Applications

- Supermarket chain suppliers

- Export manufacturers

- OEM/Private label noodle brands

- School and disaster-relief food production

- Military and emergency supplies

12.3 Pilihan pembungkusan

- Plastic/paper wrapping for blocks

- Pre-packed cups with flavor sachets

- Vacuum sealing for export-grade noodles

13. Advantages of Automating Instant Noodle Production

Automating your noodle production offers multiple benefits:

13.1 Peningkatan kecekapan

- Higher output with less manpower

- Berterusan 24/7 operation with minimal downtime

13.2 Consistency and Quality Control

- Uniform taste, saiz, dan tekstur

- Reduced human error in mixing and cutting

13.3 Kebersihan dan keselamatan

- Stainless steel food-grade materials

- Closed systems reduce contamination risk

13.4 Penjimatan kos

- Lower labor costs over time

- Minimal ingredient waste

13.5 Skalabiliti

- Easy to upgrade from 10,000 kepada 300,000 packs/day by adding modules

14. Compliance and Safety Standards

When investing in an instant noodle making machine, make sure it complies with national and international food safety standards:

14.1 Materials and Construction

- All food-contact parts should be made from SUS 304 Keluli tahan karat.

- Electrical components should be CE/UL certified.

14.2 Sanitation Standards

- Easy disassembly for cleaning

- Drainage system to prevent water accumulation

14.3 Pensijilan antarabangsa

- Persijilan CE (Eropah)

- ISO 9001 quality management system

- FDA food safety guidelines (if exporting to the US)

- SGS/BV inspection for export quality control

15. Kesimpulan

The instant noodle making machine is a powerful, serba boleh, and profitable solution for businesses looking to enter or expand in the instant food industry. Whether you are producing traditional fried noodles or venturing into healthier non-fried alternatives, the technology today can fully automate the process with high precision, Kebersihan, dan kebolehpercayaan.

Dengan memahami komponen, installation steps, spesifikasi teknikal, and maintenance procedures, you’ll be well-positioned to make an informed investment. Whether you’re a small-scale startup or a large international brand, a customized instant noodle production line can help you meet growing consumer demands while ensuring product quality and factory efficiency.

For more information or to inquire about a tailored solution, hubungi Mesin Makanan DT, a professional manufacturer of instant noodle machinery with global service and support.

Appendix: Sample Layout for an Automatic Instant Noodle Production Line

- Pengadun Doh

- Vertical Dough Feeder

- Compound Rolling Machine

- Continuous Rolling System

- Slitter and Cutter

- Steam Cooking Tunnel

- Block Shaper

- Frying or Drying Tunnel

- Penghantar Penyejuk

- Weight Checker

- Mesin pembungkusan

Appendix: Instant Noodle Production Line Technical Sheet

| Parameter | Nilai |

|---|---|

| Model | DTM-IN200 |

| Kapasiti output | 200,000 packs/8h |

| Total Length | 42 meter |

| Installed Power | 135 kW |

| Electricity Requirement | 380V, 50Hz, 3 phase |

| Suhu menggoreng | 150°C ± 5°C |

| Oil Consumption | 100–200L/day |

| Dryer Temp (Non-Fried) | 85–110°C |

| Kelajuan pembungkusan | 100–150 packs/min |

| Cooling Time | 3–5 minutes |

| Operator Needed | 3–5 people |

| Berat Mesin | Lebih kurang. 10 tons |