1. Pengenalan

Pasaran pencuci mulut beku berkembang pada kadar yang belum pernah terjadi sebelumnya. Dari panti ais krim tempatan ke rantai makanan segera yang besar, kerucut ais krim yang rendah hati tetap menjadi kegemaran di kalangan semua demografi. Memandangkan permintaan untuk reka bentuk kon yang inovatif dan pengeluaran besar -besaran berkembang, melabur dalam mesin pembuat kerucut ais krim telah menjadi langkah strategik bagi usahawan dan pelabur.

Ini menganalisis daya maju ekonomi pelaburan sedemikian, memberikan pandangan tentang potensi pasaran, Pulangan yang dijangkakan, dan strategi untuk memaksimumkan keuntungan.

2. Gambaran Keseluruhan Pasaran Ice Cream Global

- Penilaian (2025): $93.2 bilion (Dianggarkan oleh Statista)

- Kadar pertumbuhan: CAGR OF 5.6% melalui 2030

- Pasaran utama: Amerika Syarikat, Eropah, China, India, Brazil

- Trend: Penyesuaian, Bahan -bahan organik, Cone Premium, Pilihan Vegan

Cones adalah elemen penting dalam ekosistem ini -bukan hanya sebagai kapal tetapi sebagai penambah pengalaman. Pengeluaran dan pelbagai mereka mempengaruhi pembezaan jenama yang ketara.

3. Permintaan yang semakin meningkat untuk kerucut ais krim

Pengguna bergerak jauh dari cawan ke kerucut untuk sentuhan, bebas sisa, dan pengalaman yang layak foto. Data pasaran mencadangkan:

- Servis berasaskan kerucut akaun lebih 60% jualan ais krim yang dijual dan salon.

- Permintaan eksport untuk kerucut di kawasan seperti Afrika, Asia Tenggara, dan Timur Tengah telah berkembang kerana peningkatan suhu dan perbelanjaan pengguna.

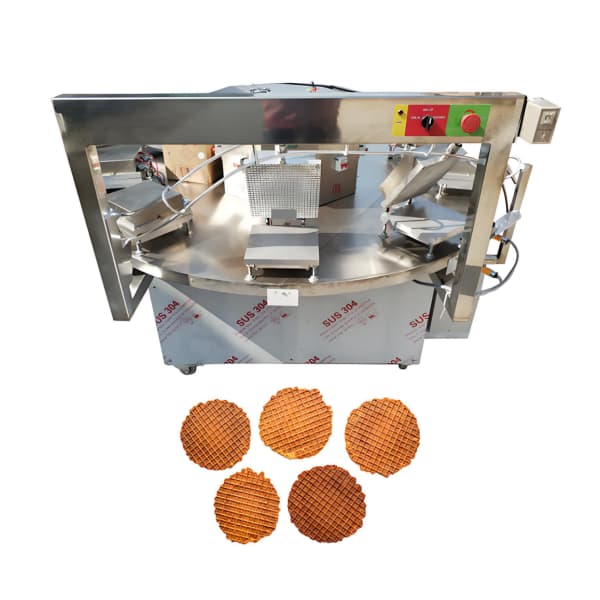

4. Apa itu mesin pembuat ais krim?

An Mesin pembuat kerucut ais krim adalah peranti perindustrian yang mengautomasikan pengeluaran kerucut ais krim dari penyediaan adunan hingga membentuk dan membakar. Mesin boleh:

- Menghasilkan Cone Gula, Wafer Cones, Kon roll telur, Dan bahkan Kon yang direka khas

- Beroperasi secara berterusan untuk pengeluaran berskala besar

- Menjadi automatik atau separa automatik sepenuhnya

Jenis mesin termasuk:

- Mesin Rotary Cone (Jumlah yang tinggi)

- Mesin kerucut rata automatik

- Mesin jenis roller (Sesuai untuk kerucut tangan)

5. Rasional Pelaburan

1. Kos bahan mentah yang rendah

Tepung, gula, minyak, dan telur murah dan boleh diakses secara global.

2. Permintaan yang tinggi

Sektor perkhidmatan runcit dan makanan yang sentiasa memerlukan bekalan kon.

3. Skalabiliti

Mulakan kecil dan berkembang ke garisan automatik sepenuhnya dengan gangguan yang minimum.

4. Keuntungan jangka panjang

Mesin mempunyai jangka hayat 7-10 tahun dengan penyelenggaraan yang betul, Menjana ROI yang konsisten.

6. Analisis keuntungan

Purata harga jualan setiap kon (Borong):

- $0.03 kepada $0.08, Bergantung pada rantau dan saiz

Kapasiti pengeluaran:

- 2000 kepada 8000 Cone/jam, Bergantung pada model

Output harian (8-Peralihan jam):

- Purata: 16,000 kepada 64,000 kon

Anggaran Hasil Harian:

- Harga akhir rendah: 16,000 x $0.03 = $480/hari

- Harga mewah: 64,000 x $0.08 = $5,120/hari

Potensi pendapatan bulanan (26 hari bekerja):

- Julat: $12,480 - $133,120

7. Pecahan kos perniagaan pengeluaran ais krim

| Item kos | Anggaran kos (USD) |

|---|---|

| Mesin Maker Cone (Auto) | $10,000 - $50,000 |

| Bahan mentah (Bulanan) | $3,000 - $7,000 |

| Elektrik & Utiliti | $1,000 - $2,000 |

| Buruh (2-4 pengendali) | $1,500 - $4,000 |

| Pembungkusan | $800 - $2,000 |

| Sewa (Pilihan) | $500 - $2,000 |

| Penyelenggaraan (Setiap tahun) | $1,000 - $2,500 |

8. Pengiraan ROI: Contoh kajian kes

Harga Mesin: $30,000

Hasil bulanan: $30,000

Kos operasi bulanan: $8,000

Keuntungan bersih bulanan: $22,000

Tempoh bayaran balik: Kurang daripada 2 bulan

Potensi keuntungan bersih tahunan: $264,000+

Walaupun dengan nombor konservatif, ROI dicapai dengan cepat -menjadikannya salah satu pelaburan pemprosesan makanan yang paling menguntungkan di bawah $50,000.

9. Ciri -ciri utama dan parameter teknikal

| Ciri | Spesifikasi |

|---|---|

| Bekalan kuasa | 380V / 50Hz / 3 Fasa |

| Kaedah Pemanasan | LPG/gas asli atau elektrik |

| Kapasiti | 2000-8000 PC/jam |

| Julat saiz kerucut | 30mm - 180mm |

| Panel Kawalan PLC | Ya |

| Bahan | Keluli tahan karat 304 |

| Kawalan suhu | Automatik |

Mesin boleh disesuaikan dengan acuan kerucut bentuk dan tekstur yang berbeza untuk memenuhi keperluan penjenamaan.

10. Aliran kerja talian pengeluaran

- Penyediaan adunan - Sistem pencampuran automatik

- Membentuk & Baking - Plat haba membentuk dan membakar kerucut

- Bergulir atau melipat - Berdasarkan gaya yang dikehendaki

- Penyejukan & Pengeringan -Cones disejukkan udara untuk mengekalkan kesakitan

- Menyusun & Pembungkusan - Lengan manual atau robot boleh ditambah

- Pemeriksaan berkualiti -Pemeriksaan berasaskan sensor atau manual

11. Strategi kemasukan pasaran

- Rantaian bekalan B2B: Bekerjasama dengan pengeluar ais krim, Bakeri, dan rantai makanan segera

- Pengeluaran berorientasikan eksport: Kesan permintaan dari Afrika, Timur Tengah, dan Asia Selatan

- Kontrak label peribadi: Kon pengilang untuk syarikat pencuci mulut berjenama

- Bekalan francais: Menjadi pembekal kon eksklusif untuk kedai rantai

12. Sasaran segmen pelanggan

- Pengilang ais krim

- Kios ais krim tempatan

- Jenama pencuci mulut beku

- Katerer Hotel dan Resort

- Pengedar borong B2B

- Agensi eksport

13. Piawaian dan pematuhan yang berkualiti

Untuk memastikan kejayaan dan eksport pasaran:

- Ikuti HACCP dan ISO 22000 untuk keselamatan makanan

- Gunakan BPA-bebas, acuan gred makanan

- Pastikan pensijilan CE/UL untuk keselamatan elektrik

- Daftar dengan FDA atau Pihak Berkuasa Makanan Tempatan

14. Strategi risiko dan mitigasi

| Risiko | Penyelesaian |

|---|---|

| Downtime peralatan | AMC atau Juruteknik Dalam Negeri |

| Ketepuan pasaran | Kepelbagaian produk (mangkuk wafel) |

| Kelewatan pengawalseliaan | Bekerjasama dengan perunding pematuhan |

| Permintaan bermusim | Gunakan untuk pengeluaran biskut/bungkus kon |

15. Penyelenggaraan dan jangka hayat

Dengan penyelenggaraan biasa:

- Jangka hayat yang dijangkakan: 7-10 tahun

- Downtime/tahun: <3%

- Bahagian ganti kos/tahun: <$1,000

Penyelenggaraan pencegahan termasuk:

- Pembersihan harian

- Pelinciran bulanan galas

- Pemeriksaan Komponen Elektrik Bi-Tahunan

16. Mengapa sekarang adalah masa terbaik untuk melabur

- Meningkatkan suhu global: Meningkatkan Jualan Ais Krim

- Modal kecil, Pulangan tinggi

- Peningkatan permintaan untuk kerucut artisanal

- Ledakan di pasaran eksport untuk kerucut

- Perniagaan Kemelesetan-Proof: Makanan makanan tetap popular walaupun semasa kemerosotan

17. Kesimpulan

Melabur dalam mesin pembuat kerucut ais krim bukan sekadar membuat kerucut -ini mengenai memasuki berskala, menguntungkan, dan niche pembuatan makanan di peringkat global. Dengan peralatan yang betul, Strategi Pemasaran, dan kawalan kos, anda boleh menjana pulangan besar dengan risiko operasi yang rendah.

Sama ada anda seorang usahawan makanan, Pelabur PKS, atau pengeluar yang berfokus pada eksport, mesin ini boleh menjadi pintu masuk anda untuk pulangan pelaburan yang manis.