Automatic Ice Cream Cone Machine and Its Functions

An automatic ice cream cone machine is a type of industrial food equipment designed for producing large volumes of wafer cones. The structure usually includes a batter mixer, baking plates, rolling system, and automatic stacking device. Its purpose is to deliver consistent, lightweight wafer cones that are widely used in ice cream packaging for supermarkets and fast-food chains.

Working Process of Automatic Ice Cream Cone Machine

The automatic system pours measured batter into multiple baking plates, bakes it evenly, and rolls it into cone shapes with precision molds. The automation ensures a high-speed production line, typically ranging from 3,000 to 10,000 cones per hour.

Industrial Ice Cream Cone Production Line Compared with Waffle Cone Machines

An industrial ice cream cone production line represents a higher level of automation, suitable for mass manufacturing. In contrast, a waffle cone machine is generally small-scale and semi-manual, designed for artisanal cone production in cafés or boutique ice cream shops.

Difference in Output Capacity

- Ice Cream Cone Machine: 3,000–10,000 pcs/hour.

- Waffle Cone Machine: 50–500 pcs/hour.

This makes ice cream cone machines suitable for factories, while waffle cone machines are more appropriate for small businesses focusing on fresh, handmade cones.

Commercial Ice Cream Cone Baking Equipment and Market Use

The commercial ice cream cone baking equipment is primarily applied in medium-sized enterprises. It ensures stable production and reduced labor cost compared to waffle cone machines, which require more manual involvement.

Market Application of Commercial Ice Cream Cone Baking Equipment

- Factories and wholesalers rely on wafer cone machines.

- Cafés and restaurants prefer waffle cone machines for in-house cone preparation.

This highlights the fundamental difference in their business applications.

Semi Automatic Ice Cream Cone Maker vs. Waffle Cone Device

A semi automatic ice cream cone maker is an entry-level model that balances manual operation with partial automation. This differs greatly from waffle cone devices, which are predominantly manual.

Comparative Advantages

- Semi automatic ice cream cone maker: higher efficiency, standardized cone size.

- Waffle cone machine: flexibility in design, but slower production speed.

Wafer Cone Ice Cream Machine in Industrial Production

The wafer cone ice cream machine focuses on producing lightweight cones. These wafer cones are cost-efficient, easy to package, and popular in global markets.

Contrast with Waffle Cones

Wafer cones produced by an ice cream cone machine are thin and crispy, while waffle cones are thicker, richer in taste, and often consumed as a premium option.

Sugar Cone Ice Cream Machine and Flavor Comparison

A sugar cone ice cream machine creates cones with caramelized flavor and crunchy texture. Waffle cones, while similar in sweetness, are generally denser and require different batter composition including eggs and butter.

Production Technology

- Ice Cream Cone Machine: Standardized molds, consistent flavor, large volume.

- Waffle Cone Machine: Variable recipes, customized thickness, artisanal approach.

Tunnel Type Ice Cream Cone Machine in Continuous Operation

The tunnel type ice cream cone machine represents a large-scale automated system. Its continuous tunnel design enables uninterrupted production, which contrasts with the batch-style operation of waffle cone machines.

Efficiency Difference

- Tunnel type machines: automated, hygienic, 10,000+ pcs/hour.

- Waffle cone machines: manual, labor-intensive, small-batch only.

Rotary Ice Cream Cone Oven and Production Flexibility

The rotary ice cream cone oven uses rotation for uniform baking. This ensures every cone has consistent thickness and appearance, which is crucial for high-standard production lines.

Comparison with Waffle Cone Machines

Waffle cone devices depend on operator skill for even baking, leading to higher variability in product quality. Rotary ice cream cone ovens eliminate this inconsistency.

Technical Comparison Between Ice Cream Cone Machine and Waffle Cone Machine

| Parameter | Ice Cream Cone Machine | Waffle Cone Machine |

|---|---|---|

| Cone Type | Wafer or sugar cone | Waffle cone |

| Output | 3,000–10,000 pcs/hour | 50–500 pcs/hour |

| Automation | Fully/semi automatic | Manual/semi-automatic |

| Ingredients | Flour, sugar, oil, water | Flour, sugar, butter, eggs |

| Market | Industrial, wholesale | Cafés, shops |

This table shows that the ice cream cone machine is designed for standardized, industrial production, while waffle cone machines serve niche, artisanal markets.

Maintenance of Ice Cream Cone Machine Compared to Waffle Cone Machine

Maintaining an ice cream cone machine requires regular cleaning of baking plates, lubrication of chains, and replacement of worn molds. In contrast, waffle cone machines require only basic cleaning, but frequent operator supervision due to manual processes.

Long-Term Investment Perspective

- Ice cream cone machines: higher initial cost, long-term efficiency.

- Waffle cone machines: lower cost, but limited scalability.

Frequently Asked Questions About Ice Cream Cone Machine

1. What is an Ice Cream Cone Machine used for?

An ice cream cone machine is used for producing wafer or sugar cones in large quantities. It automates the baking, shaping, and stacking process, which is ideal for industrial food factories.

2. How does an Automatic Ice Cream Cone Machine work?

The automatic ice cream cone machine works by distributing batter into heated molds, baking it to the correct texture, rolling it into cone shapes, and automatically stacking them for packaging.

3. What is the difference between Ice Cream Cone Machine and Waffle Cone Machine?

The main difference is scale and automation. Ice cream cone machines are industrial systems producing 3,000–10,000 wafer cones per hour, while waffle cone machines are smaller, semi-manual devices that produce artisanal cones in small batches.

4. What are the benefits of an Industrial Ice Cream Cone Production Line?

An industrial ice cream cone production line reduces labor costs, increases efficiency, and ensures consistent cone quality. It is suitable for large-scale factories and exporters.

5. What type of cones can be made with Ice Cream Cone Machine?

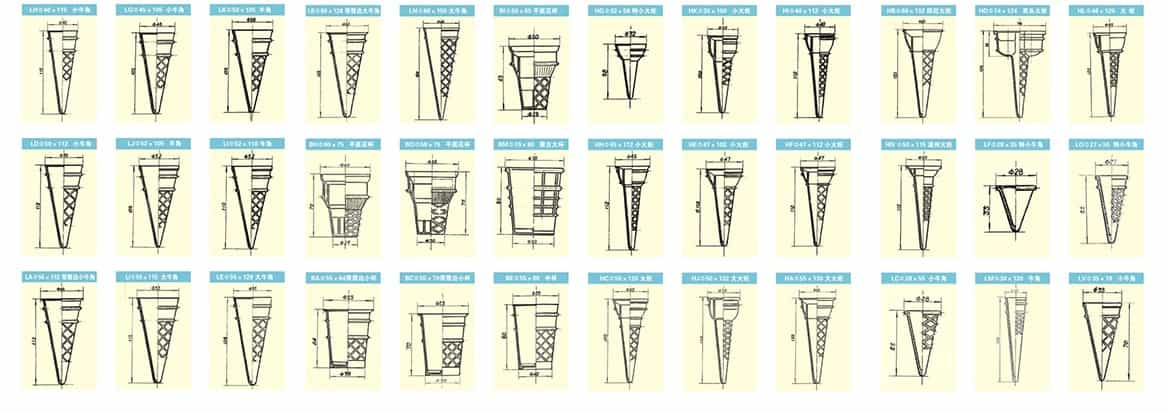

Depending on the molds, an ice cream cone machine can produce wafer cones, sugar cones, and customized cone designs for branding needs.

6. What is the difference between Wafer Cone Ice Cream Machine and Waffle Cone Machine?

A wafer cone ice cream machine produces light, thin, and crispy cones, while a waffle cone machine creates thick, artisanal cones with a buttery flavor.

7. How much does an Ice Cream Cone Machine cost?

The price of an ice cream cone machine varies:

- Semi-automatic: USD 3,000–8,000

- Commercial: USD 10,000–20,000

- Industrial: USD 30,000–100,000+

8. How to maintain an Ice Cream Cone Machine?

Maintenance involves cleaning baking plates daily, lubricating moving parts weekly, and inspecting heating systems regularly. Proper care extends the lifespan to 8–12 years.

9. Which businesses should use Ice Cream Cone Machine?

Factories, wholesale suppliers, and large ice cream manufacturers should invest in ice cream cone machines. In contrast, ice cream shops and cafés typically use waffle cone machines.

10. Can one Ice Cream Cone Machine produce multiple cone sizes?

Yes. By changing molds, an ice cream cone machine can produce cones of different lengths, diameters, and patterns to meet various market demands.

Difference between ice cream cone machine and waffle cone machine

The difference between ice cream cone machine and waffle cone machine lies in automation level, output scale, product type, and target market.

- Ice Cream Cone Machine: Designed for industrial wafer cone or sugar cone mass production, offering high efficiency and consistency.

- Waffle Cone Machine: Built for small-scale, artisanal waffle cones, emphasizing freshness and flavor customization.

For businesses seeking large-scale, standardized production, the ice cream cone machine is the optimal solution. For shops focusing on handmade, premium cones, the waffle cone machine remains suitable.