1. Introduction

The bubble washing machine vegetable and fruit is an advanced piece of equipment designed for cleaning fresh produce using a combination of water immersion and air bubble agitation. This cleaning method is gentle, efficient, and environmentally friendly, making it suitable for both delicate and firm produce.

As global consumers increasingly demand ready-to-eat, pre-washed, and organic-certified produce, processors are upgrading from traditional manual washing to fully automated bubble washing systems.

1.1 Why Bubble Washing Matters in Modern Food Processing

- Food Safety Compliance

Regulatory agencies such as the FDA, EU Commission, and CFIA require food producers to minimize microbial contamination, pesticide residues, and physical debris. - Product Quality Preservation

Bubble washing prevents bruising, discoloration, and nutrient loss, especially important for export markets. - Operational Efficiency

Handles high volumes — from 500 kg/h for small plants to 10,000+ kg/h for large industrial facilities.

2. How a Bubble Washing Machine Works

A bubble washing machine vegetable and fruit uses air bubbles generated by a blower to gently agitate produce in water, loosening dirt and contaminants.

2.1 The Process Flow

- Loading

Produce enters via a conveyor or manual hopper. - Water Tank Immersion

Fruits and vegetables are fully submerged. - Bubble Injection

Compressed air enters through perforated pipes, creating turbulence. - Dirt Separation

Heavy particles settle, light debris floats away. - Final Rinse

Clean water sprays remove any residual contaminants. - Discharge

A conveyor transfers produce to the next processing stage.

2.2 Key Science Behind Bubble Cleaning

- Hydrodynamic Effect: Bubbles create micro-currents that penetrate leaf folds.

- Surface Tension Reduction: Air bubbles reduce adhesion between dirt and produce skin.

- Oxygen Enrichment: Helps maintain freshness during cleaning.

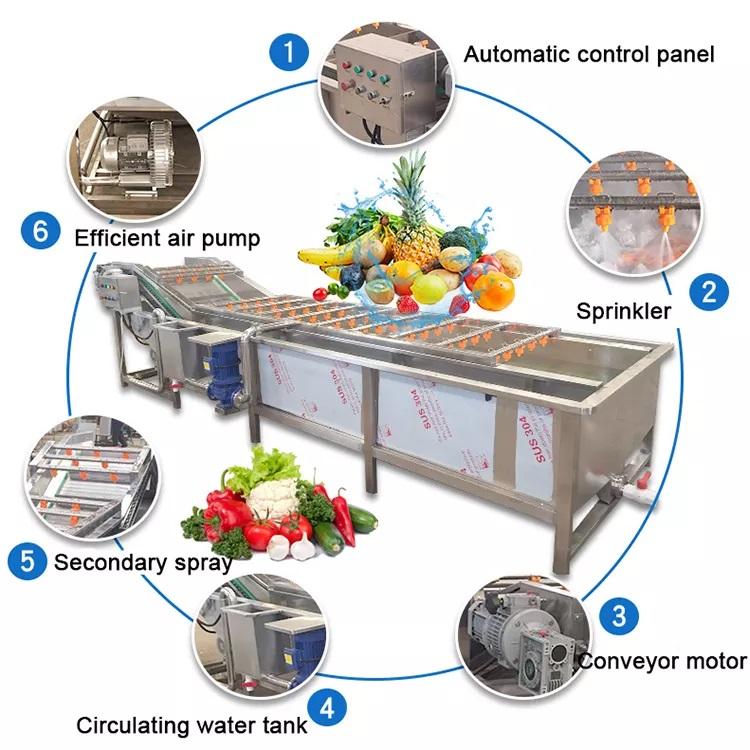

3. Machine Design & Components

The bubble washing machine vegetable and fruit is engineered for durability, hygiene, and easy cleaning.

| Component | Function |

|---|---|

| Water Tank | Holds the washing solution. |

| Air Blower | Generates air for bubble production. |

| Mesh Conveyor | Moves produce through the cleaning zone. |

| Sediment Trap | Collects heavy debris. |

| Overflow Outlet | Removes floating impurities. |

| Rinse Section | Provides final clean water spray. |

| Control Panel | Manages speed, air flow, and water circulation. |

Material: SUS304 stainless steel (standard), SUS316 for highly acidic produce.

4. Technical Parameters Table

| Model | Capacity (kg/h) | Power (kW) | Water Volume (L) | Dimensions (mm) | Weight (kg) | Material |

|---|---|---|---|---|---|---|

| DT-500 | 500 | 2.2 | 400 | 3000×1000×1300 | 280 | SUS304 |

| DT-1000 | 1000 | 3.7 | 600 | 4000×1200×1300 | 380 | SUS304 |

| DT-2000 | 2000 | 5.5 | 900 | 5000×1400×1350 | 520 | SUS304 |

| DT-3000 | 3000 | 7.5 | 1200 | 6000×1500×1400 | 650 | SUS304 |

| DT-5000 | 5000 | 11 | 1500 | 8000×1600×1450 | 950 | SUS304 |

5. Product Applications

- Leafy Greens: Lettuce, spinach, kale, cabbage.

- Root Vegetables: Carrots, potatoes, radishes, beets.

- Fruits: Strawberries, grapes, apples, citrus.

- Herbs: Mint, basil, coriander.

- Medicinal Plants: Ginseng, chrysanthemum.

6. Benefits Over Other Washing Methods

| Feature | Bubble Washing Machine | Spray Washing | Manual Washing |

|---|---|---|---|

| Damage to Produce | Very Low | Medium | Variable |

| Cleaning Thoroughness | High | Medium | Low |

| Labor Requirement | Low | Medium | High |

| Water Use Efficiency | High | Medium | Low |

7. Installation Guide

- Select Location – Level floor, near water & drainage.

- Install Utilities – Connect 3-phase power, water inlets, and drainage.

- Assembly – Attach blower, conveyor, and rinse sections.

- Testing – Run with water only to check for leaks.

8. Operation Tips

- Pre-rinse heavily soiled produce before loading.

- Adjust bubble intensity for delicate items.

- Keep water temperature low to maintain freshness.

9. Maintenance Schedule

| Frequency | Action |

|---|---|

| Daily | Drain & clean tank, rinse filters. |

| Weekly | Inspect blower and pump. |

| Monthly | Remove scaling, sanitize tank. |

| Yearly | Replace seals, bearings. |

10. Water & Energy Saving Features

- Recirculation system reuses up to 80% of water.

- Automatic debris removal extends water life.

- Variable blower speed reduces power use.

11. Case Studies

Case 1 – Leafy Green Processor in California

- Capacity: 3000 kg/h

- Result: Reduced labor by 70%, water use by 40%.

- ROI: Achieved in 14 months.

Case 2 – Berry Exporter in Chile

- Capacity: 2000 kg/h

- Result: Reduced bruising damage from 6% to under 1%.

12. Market Trends

- Rising demand for organic-certified washed produce.

- Increasing adoption in Asia-Pacific due to export markets.

- Integration with optical sorting machines.

13. How to Choose the Right Machine

- Capacity Requirements

- Product Type

- Space Availability

- Budget and ROI Goals

- After-Sales Support

14. Price Ranges

- Small (500–1000 kg/h): $2,500–$5,000

- Medium (2000–3000 kg/h): $6,000–$10,000

- Large (5000+ kg/h): $12,000–$20,000+

15. Extended FAQs

Q: Can it be used for seafood?

A: Yes, with proper corrosion protection.

Q: Can it connect to peeling machines?

A: Yes, commonly integrated in full processing lines.

Q: Is ozone disinfection available?

A: Yes, as an optional add-on.

16. Troubleshooting Guide

| Problem | Possible Cause | Solution |

|---|---|---|

| Weak bubbles | Low blower pressure | Check blower filter |

| Poor cleaning | Overloaded tank | Reduce feed rate |

| Water overflow | Blocked drain | Clean outlet |

17. Conclusion

A bubble washing machine vegetable and fruit is not just a cleaning device — it’s a productivity, quality, and safety investment. With the right model, you can increase throughput, improve hygiene, and reduce operational costs.