Introduction

The global love for crispy, golden French fries has driven an ever-increasing demand in restaurants, fast food chains, and frozen food industries. To meet this demand efficiently, many manufacturers and entrepreneurs are turning to the Automatic Potato French Fries Machine Production Line. This fully integrated system simplifies potato processing, increases productivity, and ensures consistent quality.

We will explore the complete setup, cost breakdown, and key machinery of an automatic French fries production line. Whether you’re a small-scale food processor or an industrial giant, this guide is tailored to help you make informed decisions.

Why Choose an Automatic French Fries Machine Production Line?

The transition from manual to automatic processing brings numerous benefits:

- Higher Efficiency: Streamlined operations with continuous processing.

- Improved Hygiene: Stainless steel equipment meets food-grade standards.

- Labor Savings: Reduces manpower needs by up to 70%.

- Consistent Quality: Uniform cutting, frying, and packaging.

- Scalability: Suitable for small, medium, and large operations.

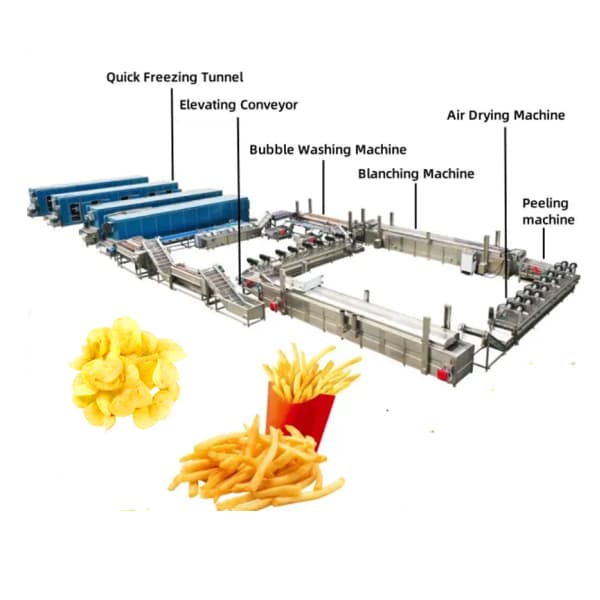

Core Machines in a French Fries Production Line

Each machine in the production line plays a specific role. Below is a detailed breakdown of the essential components:

1. Potato Washing and Peeling Machine

- Function: Cleans and peels raw potatoes.

- Capacity: 300 kg/h to 2000 kg/h

- Material: Food-grade SUS304 stainless steel

2. French Fries Cutting Machine

- Function: Cuts potatoes into uniform sticks.

- Adjustable Cutting Size: Common sizes include 7x7mm, 9x9mm, and 10x10mm.

- Blade Options: Straight, crinkle, or wave blade configurations.

3. Rinsing/Bubble Washing Machine

- Function: Removes surface starch from cut fries.

- Technology: Uses high-pressure air bubbles and water sprays.

4. Blanching Machine

- Function: Deactivates enzymes, preserves color and texture.

- Temperature Range: 70–90°C

- Time Range: 1–3 minutes depending on fry size

5. Dewatering Machine

- Function: Removes excess moisture post-blanching.

- Type: Centrifugal system for rapid drying

6. Continuous Frying Machine

- Function: Fries the potato sticks to golden perfection.

- Heating Options: Electric, gas, or diesel

- Temperature Control: Adjustable between 150–180°C

7. De-oiling Machine

- Function: Reduces oil content for healthier fries.

- Type: Centrifugal spinner

8. Freezing Machine (IQF Freezer)

- Function: Rapidly freezes fries to preserve texture and taste.

- Temperature: −18°C or lower

9. Weighing and Packaging Machine

- Function: Automatically fills, weighs, seals, and labels packages.

- Packaging Types: Vacuum packs, pillow bags, or bulk packaging

Complete Workflow of the Production Line

- Loading Potatoes: Raw potatoes are poured into a hopper.

- Washing and Peeling: Dirt and skin are removed.

- Cutting: Cleaned potatoes are sliced into uniform fries.

- Washing Again: Rinses off starch.

- Blanching: Preserves natural potato color.

- Dewatering: Prepares fries for frying.

- Frying: Cooks fries at the desired crispness.

- De-oiling: Reduces oil and improves shelf life.

- Freezing (Optional): For frozen French fries.

- Packaging: Fries are weighed and sealed into bags.

Technical Specifications Table

| Machine | Power (kW) | Capacity (kg/h) | Dimensions (mm) |

|---|---|---|---|

| Washing & Peeling Machine | 1.5 – 3.0 | 300 – 2000 | 1200x850x800 |

| Cutting Machine | 1.1 – 2.2 | 300 – 2000 | 950x800x1000 |

| Bubble Washing Machine | 2.2 – 4.0 | 300 – 2000 | 1800x1000x1200 |

| Blanching Machine | 6.0 – 12 | 300 – 2000 | 2200x800x1400 |

| Dewatering Machine | 1.5 | 300 – 1000 | 900x600x900 |

| Frying Machine | 30 – 120 | 300 – 2000 | 5000x1200x1800 |

| De-oiling Machine | 1.5 | 300 – 1000 | 1000x800x1000 |

| IQF Freezer | 15 – 80 | 300 – 2000 | Customizable |

| Packaging Machine | 2.0 – 5.0 | 300 – 2000 | 1500x800x1700 |

Cost Breakdown: What to Expect

The investment in an automatic French fries production line varies based on:

- Capacity

- Level of Automation

- Material Quality

- Freezing & Packaging Options

Estimated Cost Ranges:

| Production Capacity | Type | Estimated Cost (USD) |

| 100 – 300 kg/h | Semi-automatic line | $10,000 – $30,000 |

| 500 – 1000 kg/h | Fully automatic mid-size | $40,000 – $90,000 |

| 1000 – 2000+ kg/h | Industrial scale line | $100,000 – $300,000+ |

Additional costs may include:

- Factory setup and installation

- Shipping and customs duties

- Maintenance tools and spare parts

- Employee training

Factory Setup Requirements

Space Requirements:

- Small line (300 kg/h): 100 – 150 m²

- Large line (2000 kg/h): 500 – 800 m²

Utilities:

- Electricity: 30 – 150 kW depending on the setup

- Water: 3 – 10 m³/h

- Oil for Fryer: Initial fill of 200 – 500 liters

Workforce:

- Operators needed: 3 – 6 (for fully automatic line)

- Training time: 3 – 5 days with supplier support

Profitability and ROI

Let’s consider a mid-size factory producing 1000 kg/h:

- Daily Output: ~8,000 kg (8 hours)

- Wholesale Price: $1.2 – $2.0 per kg (varies by region)

- Daily Revenue: ~$9,600 (avg. $1.2/kg)

- Monthly Revenue: ~$200,000+

ROI: Investment typically recovered in 6 to 18 months depending on local market conditions.

Choosing the Right Supplier

Look for a supplier with:

- CE/ISO certification

- Local installation services

- Spare parts availability

- Training and technical support

Top Supplier Example: DT Food Machine Co., Ltd. offers turnkey solutions, custom designs, and exports to over 60 countries.

FAQs

Q1: Can I customize the size and shape of the fries?

Yes, machines support multiple cutting blades for straight, crinkle, or wedge fries.

Q2: Is this line suitable for both fresh and frozen fries?

Yes. By adding a freezer and nitrogen packaging, the line can produce frozen fries.

Q3: What if I want to expand production later?

These lines are modular and scalable. Additional machines or larger capacity modules can be added.

Q4: How long does it take to install the entire line?

Installation and testing typically take 7 – 15 days depending on complexity.

Q5: How do I maintain the equipment?

Regular cleaning, monthly inspection, and yearly part replacement are usually sufficient.

Conclusion

Investing in an Automatic Potato French Fries Machine Production Line and small scale french fries production line offers unmatched efficiency, consistency, and profit potential. Whether you’re looking to launch a frozen fries brand or supply fast food chains, an automated line ensures your product meets the highest standards.

With scalable configurations, reliable performance, and high ROI, this production line is a strategic move for any food processing entrepreneur or investor.