Introduction to Crepe Making Machine

A Crepe Making Machine is a professional food processing machine designed to produce crepes efficiently, consistently, and hygienically. Crepes, known for their thin texture and versatility, are popular in cafés, street food stalls, dessert shops, fast-food restaurants, hotels, and industrial food factories worldwide. As consumer demand continues to grow, manual crepe production is no longer sufficient for businesses that require high output, standardized quality, and cost efficiency.

This is where the commercial crepe making machine, automatic crepe maker, and industrial crepe making machine become essential tools. These machines help businesses improve productivity, reduce labor costs, and deliver uniform crepes at scale.

What Is a Crepe Making Machine?

A Crepe Making Machine is a specialized food equipment that automates the process of spreading batter, heating, cooking, and sometimes flipping crepes. Depending on the level of automation, it can range from semi-automatic electric crepe machines to fully automatic industrial crepe production lines.

Common alternative names and long-tail keywords include:

- Automatic crepe making machine

- Commercial crepe machine

- Electric crepe maker for business

- Industrial crepe machine

- Crepe production machine

- Professional crepe maker

- Crepe cooking machine

All these terms refer to equipment designed to produce crepes with consistent thickness, size, and texture.

How Does a Crepe Making Machine Work?

The working process of a Crepe Making Machine is simple but highly efficient:

- Batter Feeding

The crepe batter is poured manually or fed automatically into the machine through a hopper or dosing system. - Batter Spreading

A rotating drum, spreading roller, or flat heating plate evenly distributes the batter into a thin circular layer. - Heating and Cooking

The machine uses electric heating or gas heating to cook the crepe at a controlled temperature. - Flipping or Peeling

Depending on the model, the crepe may be flipped automatically or peeled off the drum after cooking. - Cooling and Collection

Finished crepes are collected manually or transferred to a conveyor for cooling and packaging.

This automated process ensures uniform cooking, stable output, and high food safety standards.

Types of Crepe Making Machines

1. Manual and Semi-Automatic Crepe Making Machine

A semi-automatic crepe making machine usually requires manual batter pouring and crepe removal but automates heating and spreading. These machines are ideal for:

- Small cafés

- Food trucks

- Street food vendors

- Startup businesses

They are compact, easy to operate, and affordable.

2. Commercial Crepe Making Machine

A commercial crepe making machine is designed for continuous daily use. It offers:

- Higher output capacity

- Durable food-grade materials

- Precise temperature control

- Stable performance

This type of crepe maker for business is commonly used in restaurants, dessert chains, and shopping malls.

3. Fully Automatic Crepe Making Machine

A fully automatic crepe making machine integrates batter feeding, spreading, cooking, and discharge into one system. Advantages include:

- Minimal labor requirement

- High consistency

- Continuous production

- Suitable for standard-sized crepes

These machines are perfect for medium to large food operations.

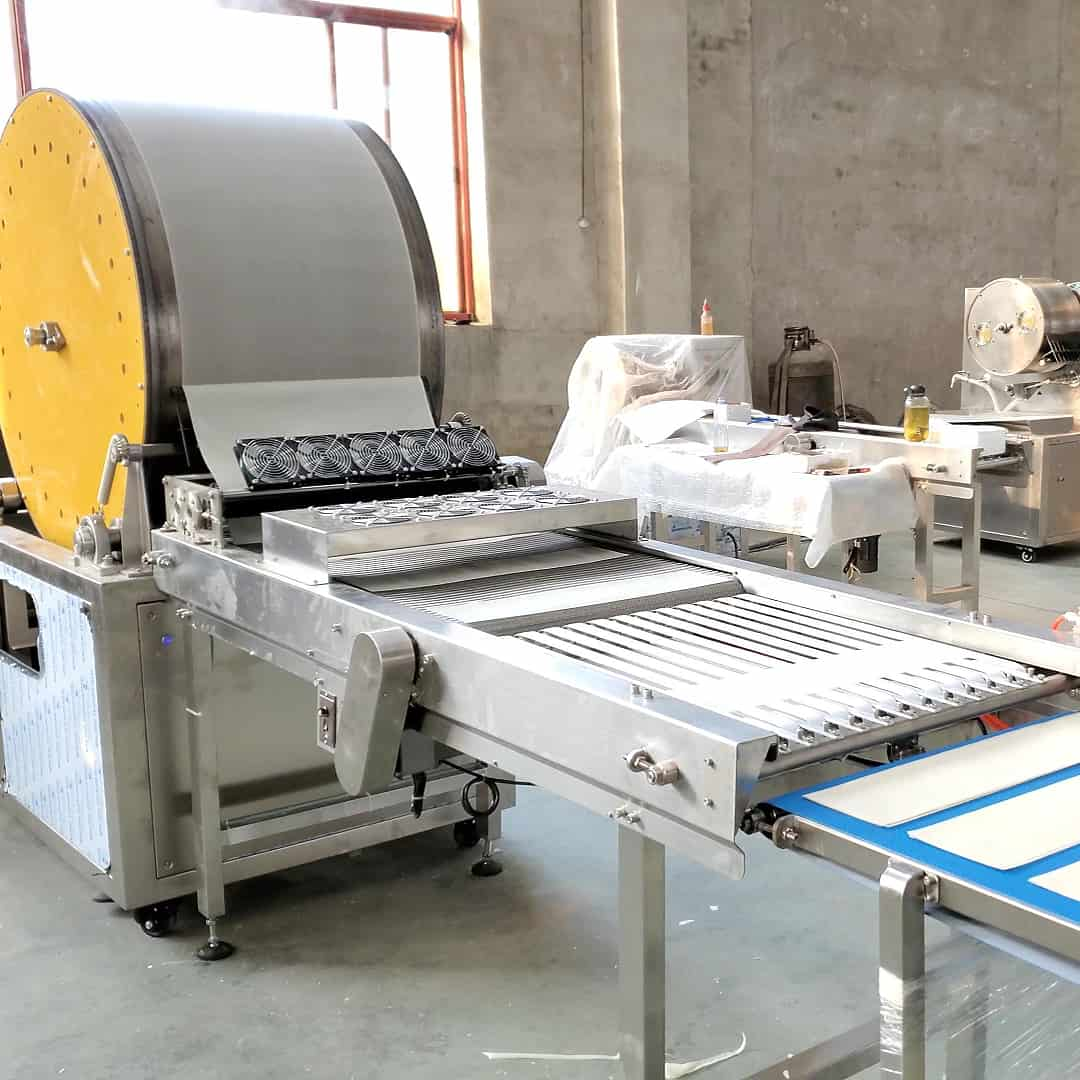

4. Industrial Crepe Making Machine

An industrial crepe making machine is designed for large-scale production and food factories. It often works as part of a crepe production line and can be integrated with cooling, stacking, and packaging systems.

Key features include:

- High output capacity

- PLC control system

- Continuous drum cooking

- Easy cleaning and maintenance

Key Features of a Crepe Making Machine

A high-quality Crepe Making Machine typically includes the following features:

- Food-grade stainless steel structure

- Accurate temperature control

- Uniform batter spreading system

- Non-stick cooking surface

- Energy-efficient heating

- Stable and safe operation

- Easy cleaning and maintenance

Advanced models may also include:

- PLC touch screen control

- Adjustable crepe thickness

- Adjustable diameter

- Automatic stacking system

Applications of Crepe Making Machine

The Crepe Making Machine has a wide range of applications across different industries:

Food Service Industry

- Cafés and bakeries

- Dessert shops

- Fast food restaurants

- Hotels and resorts

Street Food and Retail

- Food trucks

- Night markets

- Shopping mall kiosks

Food Processing Industry

- Frozen crepe production

- Ready-to-eat crepe packaging

- Central kitchens

- Catering companies

Because crepes can be sweet or savory, the commercial crepe machine supports diverse menu options.

Advantages of Using a Crepe Making Machine

1. Higher Production Efficiency

Compared with manual cooking, a crepe making machine significantly increases output and speed.

2. Consistent Product Quality

Automated temperature and spreading ensure uniform crepe thickness and texture.

3. Reduced Labor Costs

One operator can manage multiple machines, lowering staffing expenses.

4. Improved Food Safety

Food-grade materials and controlled processes meet hygiene standards.

5. Scalability for Business Growth

From small shops to industrial factories, crepe machines support scalable production.

Crepe Making Machine vs Manual Crepe Cooking

| Aspect | Manual Crepe Cooking | Crepe Making Machine |

|---|---|---|

| Output | Low | High |

| Consistency | Unstable | Uniform |

| Labor Cost | High | Low |

| Hygiene | Operator dependent | Controlled |

| Scalability | Limited | Excellent |

This comparison clearly shows why businesses prefer a commercial or industrial crepe making machine.

How to Choose the Right Crepe Making Machine

When selecting a Crepe Making Machine, consider the following factors:

Production Capacity

Determine how many crepes per hour your business requires.

Level of Automation

Choose between semi-automatic, automatic, or industrial machines.

Power Source

Electric crepe making machines are cleaner and easier to control, while gas models may reduce operating costs in some regions.

Crepe Size and Thickness

Ensure the machine supports your desired crepe diameter and thickness.

After-Sales Support

Reliable technical support and spare parts availability are crucial.

Maintenance and Cleaning of Crepe Making Machine

Proper maintenance ensures long service life and stable performance:

- Clean the cooking surface daily

- Check heating elements regularly

- Inspect electrical components

- Lubricate moving parts if required

- Follow manufacturer guidelines

A well-maintained crepe making machine can operate efficiently for many years.

Market Trends of Crepe Making Machines

The global market for Crepe Making Machines is growing due to:

- Rising demand for street food

- Expansion of dessert chains

- Increased automation in food processing

- Growth of frozen and ready-to-eat food markets

Future trends include:

- Smart control systems

- Energy-saving designs

- Compact multifunctional machines

- Integration with packaging lines

Common FAQs About Crepe Making Machine

Is a crepe making machine easy to operate?

Yes, most machines are designed for simple operation with minimal training.

Can one machine produce different types of crepes?

Yes, by adjusting batter recipes and settings.

Is an automatic crepe making machine suitable for small businesses?

Absolutely. Many compact automatic models are ideal for startups.

Why Invest in a Crepe Making Machine?

A Crepe Making Machine is a smart investment for any business involved in crepe production. Whether you operate a small café or a large food factory, using a commercial or industrial crepe making machine helps you improve efficiency, ensure consistent quality, reduce labor costs, and scale your business successfully.

With the growing popularity of crepes worldwide, choosing the right automatic crepe making machine can give your business a strong competitive advantage and long-term profitability.