Introduction

In the world of frozen desserts, few treats are as iconic as the ice cream cone. Whether it’s a classic sugar cone filled with creamy vanilla or a waffle cone bursting with colorful scoops, the combination of texture and flavor is irresistible. Behind every perfect cone lies precision equipment — the ice cream cone ice cream maker.

This machine is a vital investment for ice cream shops, dessert parlors, and even small home-based businesses. It enables users to produce cones and frozen desserts efficiently, consistently, and with professional quality. In this article, we’ll dive deep into everything you need to know about ice cream cone ice cream makers — their structure, function, benefits, variations, and how to choose the right one for your needs.

1. What Is an Ice Cream Cone Ice Cream Maker?

An ice cream cone ice cream maker is a versatile piece of food equipment designed to create waffle cones or sugar cones and, in some cases, even dispense soft-serve ice cream directly into the cone. These machines combine both waffle cone production and ice cream freezing technologies into one convenient setup for professional use.

They are commonly used in:

- Ice cream parlors

- Cafeterias

- Food trucks

- Dessert factories

- Hotels and catering services

Depending on the model, some machines specialize in cone making, while others are designed to produce soft-serve ice cream served directly into cones.

2. How Does an Ice Cream Cone Ice Cream Maker Work?

The working process depends on the type of machine—cone-making, ice cream freezing, or combination units. However, the typical operation involves the following steps:

- Preparing the Batter or Mix:

For cones, the batter is made using flour, sugar, and oil. For ice cream, a dairy or non-dairy mix is prepared and loaded into the freezing chamber. - Baking or Freezing Process:

The machine either bakes the thin waffle sheets for cones or freezes the ice cream mixture until it reaches the desired texture. - Forming and Dispensing:

In cone makers, the baked waffles are rolled automatically into a cone shape. In ice cream machines, the frozen mixture is dispensed directly into cones. - Cooling and Storage:

Finished cones are cooled naturally, while ice cream is served immediately or stored in cold display units.

This integrated workflow allows users to maintain product quality while saving labor and time.

3. Types of Ice Cream Cone Ice Cream Makers

3.1 Commercial Ice Cream Cone Maker

A commercial ice cream cone maker is designed for high-capacity production, capable of producing thousands of cones per hour. These machines often feature multiple baking plates and automated rolling systems. They are perfect for factories and large dessert chains that require continuous production.

Key Benefits:

- High output capacity

- Consistent cone size and texture

- Stainless steel construction for hygiene

- Adjustable temperature control

3.2 Home Ice Cream Cone Ice Cream Maker

For small-scale operations or home users, compact home ice cream cone makers are available. These are simple to use, energy-efficient, and perfect for crafting personalized desserts.

Advantages:

- Affordable price range

- Compact size

- Easy to operate and clean

- Ideal for family or small business use

3.3 Soft Serve Ice Cream Cone Machine

The soft serve ice cream cone machine is widely used in shops and restaurants to produce smooth, creamy ice cream dispensed directly into cones. It operates by freezing a liquid mix using an internal compressor and then pushing the frozen mix through a nozzle.

Features:

- Dual or triple flavor dispensing

- Adjustable overrun and temperature settings

- Fast freezing capability

- Simple cleaning system

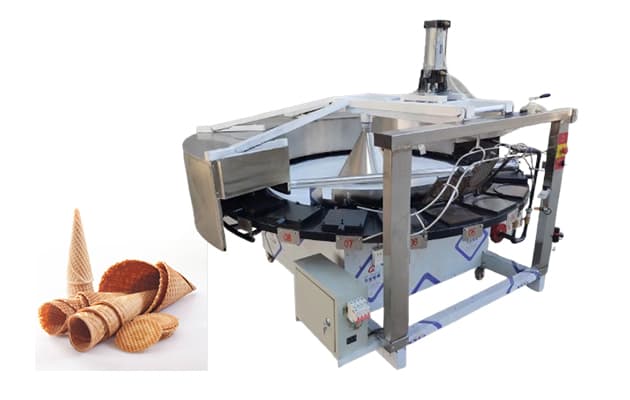

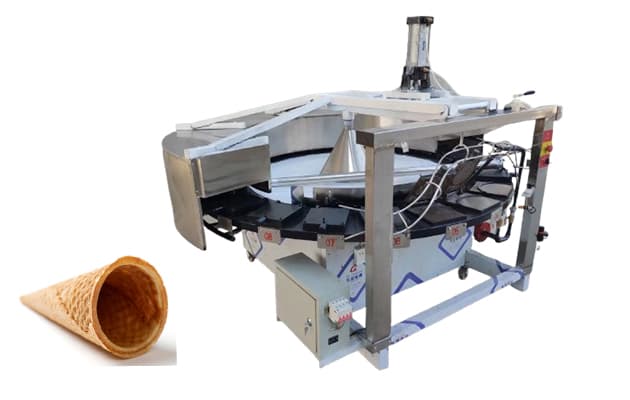

3.4 Automatic Ice Cream Cone Making Machine

An automatic cone-making machine is the industrial version of cone production equipment. It handles the full process automatically—from batter feeding to baking, forming, and stacking.

Typical Parameters:

| Model | Voltage | Power | Capacity | Cone Size | Material |

|---|---|---|---|---|---|

| DT-24C | 380V | 15 kW | 3000–5000 pcs/hr | 50–120mm | Stainless Steel 304 |

4. Key Features of Ice Cream Cone Ice Cream Maker

- High-Quality Material:

Most machines are made from food-grade stainless steel, ensuring hygiene and corrosion resistance. - Temperature Control:

Precise digital temperature control guarantees uniform baking or freezing results. - Automatic Operation:

Automatic models simplify cone rolling, stacking, or ice cream dispensing. - Energy Efficiency:

Modern models consume less power while maintaining output performance. - User-Friendly Interface:

Touchscreen or PLC control systems make operation simple even for beginners. - Customization Options:

Cone size, shape, and pattern can be adjusted according to business requirements.

5. Benefits of Using an Ice Cream Cone Ice Cream Maker

5.1 Improved Efficiency

Automation significantly reduces labor time and production costs while maintaining a consistent output.

5.2 Enhanced Product Quality

Uniform temperature control ensures crispy cones and creamy ice cream texture.

5.3 Hygiene and Safety

Made of food-safe materials, these machines meet strict sanitation standards required for food processing.

5.4 Business Growth

A high-quality machine enhances customer satisfaction, boosts sales, and allows product diversification.

5.5 Easy Maintenance

With detachable molds and easy-to-clean surfaces, maintenance becomes quick and convenient.

6. Applications in the Food Industry

The versatility of an ice cream cone ice cream maker extends beyond ice cream parlors. These machines are widely used for:

- Ice cream cone manufacturing factories

- Dessert and bakery shops

- Catering and hotel services

- Frozen yogurt and soft-serve kiosks

- Snack food companies

By producing cones and ice cream simultaneously, businesses can meet customer demand efficiently and consistently.

7. How to Choose the Right Ice Cream Cone Ice Cream Maker

7.1 Determine Your Production Needs

Estimate your daily output requirement. Small cafes may need machines producing a few dozen cones per hour, while industrial users may require thousands.

7.2 Check Power and Capacity

Review technical specifications carefully. Electric and gas-powered options cater to different production environments.

7.3 Consider Automation Level

Automatic systems minimize labor costs but require a higher initial investment. Semi-automatic models are great for mid-sized businesses.

7.4 Focus on Quality and Warranty

Always choose certified suppliers offering reliable after-sales support, spare parts, and installation guidance.

7.5 Evaluate Cost Efficiency

Balance machine cost, power consumption, and production output to ensure long-term profitability.

8. Maintenance and Cleaning Tips

- Daily Cleaning:

Wipe plates and surfaces after every use to prevent residue buildup. - Weekly Maintenance:

Lubricate moving components and check temperature calibration. - Monthly Inspection:

Inspect electrical connections and replace any worn-out parts. - Storage:

Store in a cool, dry environment to prevent corrosion or damage.

Regular maintenance extends the machine’s lifespan and ensures food safety.

9. Frequently Asked Questions (FAQs)

Q1: Can one machine make both cones and ice cream?

Some combination models can handle both processes, but industrial users often prefer separate specialized machines for better efficiency.

Q2: What cone materials can I use?

You can use standard waffle or sugar cone batter recipes with flour, sugar, and vegetable oil.

Q3: How long does a cone take to bake?

Depending on the model, a cone typically takes 1–2 minutes to bake.

Q4: Is the machine suitable for non-dairy mixes?

Yes, modern ice cream makers are compatible with both dairy and vegan/non-dairy mixes.

Q5: What’s the lifespan of an industrial ice cream cone maker?

With proper care, high-quality machines can last 8–10 years or more.

10. Why Choose DT Food Machine

DT Food Machine is a trusted global manufacturer of ice cream cone ice cream maker equipment. We specialize in designing and producing efficient, durable, and customizable machines tailored to your business needs.

Our Advantages:

- ISO and CE-certified manufacturing

- Full installation and training support

- Custom designs for cone size, texture, and output

- Global logistics and after-sales service

Whether you run a local ice cream shop or manage a full-scale food production line, DT Food Machine provides solutions that deliver consistent performance, hygiene, and profitability.

11. Future Trends in Ice Cream and Cone Production

The dessert industry is evolving rapidly, and automation is at the forefront of change. Smart ice cream cone ice cream maker machines now come with touchscreens, IoT connectivity, and AI-based temperature control. These innovations improve accuracy, reduce waste, and enhance production monitoring.

Additionally, eco-friendly materials and energy-efficient designs are becoming standard features, reflecting the growing demand for sustainable food production technologies.

12. Ice Cream Cone Ice Cream Maker

An ice cream cone ice cream maker is more than a machine — it’s the foundation of your dessert business. From small cafes to industrial-scale factories, choosing the right model directly impacts your efficiency, product quality, and profits.

When selecting your equipment, focus on automation level, output capacity, material quality, and manufacturer reliability. With advanced designs and full support from DT Food Machine, you can confidently scale your production, meet customer demand, and create ice cream cones that leave a lasting impression.