Introduction to Fried Garlic Processing Equipment

Fried garlic has become an essential condiment across global cuisines. From Asian stir-fries and soups to Western snacks and toppings, crispy fried garlic granules and flakes enhance dishes with aroma, texture, and flavor. To meet the increasing demand for uniform quality and mass production, specialized garlic frying machines and fried garlic processing lines have been developed. These machines not only maintain consistent taste and crispiness but also ensure high efficiency, food safety, and cost-effectiveness.

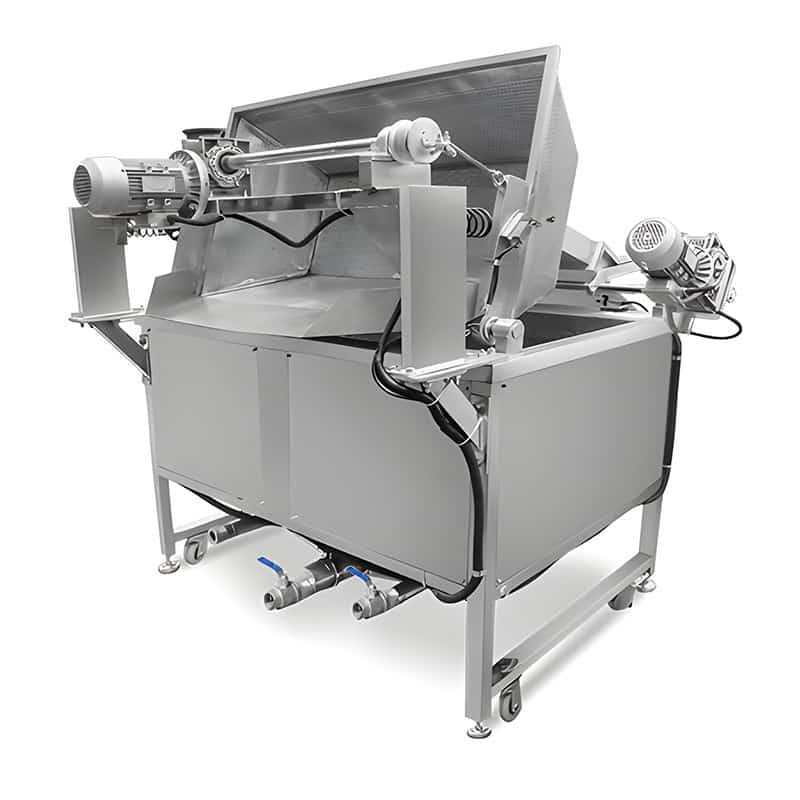

Industrial Garlic Fryer for Granules and Flakes

Automatic Garlic Frying System

An automatic garlic frying system is designed to handle high-volume production while maintaining precise control over oil temperature and frying time. Unlike traditional manual frying, automatic systems prevent overcooking, reduce oil oxidation, and deliver crispy garlic flakes with uniform golden color.

Commercial Fried Garlic Flakes Machine

Commercial garlic frying machines come in different capacities, ranging from small-scale units for restaurants to large industrial fryers for food factories. These machines are made with stainless steel construction, heat-resistant conveyors, and advanced oil filtration systems to extend oil life.

Garlic Chips and Flakes Production Line

Continuous Garlic Fryer with Conveyor

For industrial-scale operations, continuous garlic fryers with conveyor belts are the backbone of garlic processing. Garlic slices, granules, or crushed pieces are placed on a mesh conveyor, which passes through hot oil at controlled speeds. This ensures every piece is fried evenly, reducing labor cost and maximizing productivity.

Automatic Garlic Flake Processing Plant

A garlic flake processing plant integrates multiple machines, including garlic peeling machines, slicers, bubble washers, dehydration units, frying machines, deoilers, and flavor mixers. By combining these stages, the plant produces crispy fried garlic with consistent quality, ready for packaging and distribution.

Key Components of Fried Garlic Machinery

Garlic Peeling and Cutting Machines

Before frying, garlic must be peeled and cut into thin slices or granules. Automatic garlic peelers use compressed air or rubber rollers to remove skins without damaging cloves. Cutting machines slice garlic uniformly, which is essential for consistent frying results.

Oil Fryer and Heating System

The core of the process is the frying unit. Advanced garlic fryers use electricity, gas, or thermal oil heating. Temperature sensors ensure stable frying conditions, while automatic oil circulation prevents hotspots that could burn garlic pieces.

Oil Filtration and Recycling Equipment

Oil quality plays a crucial role in the taste and shelf life of fried garlic. Modern systems are equipped with continuous filtration units that remove fine particles, reducing oil consumption and improving product quality.

De-oiling and Cooling Units

After frying, garlic flakes contain excess oil. Centrifugal deoiling machines remove surface oil, improving crispiness and extending shelf life. Cooling conveyors then bring the fried garlic to ambient temperature, preventing sogginess.

Technical Parameters of Garlic Frying Equipment

| Model | Capacity (kg/h) | Power (kW) | Oil Volume (L) | Heating Method | Dimensions (mm) |

|---|---|---|---|---|---|

| GF-100 | 100 kg/h | 12 kW | 200 L | Electric | 1800 × 1000 × 1200 |

| GF-200 | 200 kg/h | 20 kW | 400 L | Gas/Electric | 2500 × 1200 × 1400 |

| GF-300 | 300 kg/h | 28 kW | 600 L | Gas/Electric | 3200 × 1500 × 1500 |

| GF-500 | 500 kg/h | 40 kW | 1000 L | Gas/Thermal Oil | 4000 × 1800 × 1600 |

Note: Technical specifications vary depending on the manufacturer and customization requirements.

Advantages of Crispy Garlic Flakes Making Machines

Uniform Quality and Taste

By controlling oil temperature and frying duration, the machines produce golden-brown garlic flakes with the same texture in every batch.

High Efficiency and Low Labor

Automation reduces the need for manual workers. Continuous fryers can process hundreds of kilograms per hour.

Energy and Oil Savings

With advanced heat exchangers and oil filtration, these machines reduce oil waste and energy costs.

Food Safety Compliance

Stainless steel construction ensures hygienic processing, meeting international food standards such as CE and ISO.

Extended Shelf Life of Products

Proper deoiling and cooling guarantee crispy texture and prevent rancidity, ensuring longer shelf life.

Applications of Fried Garlic Granules and Flakes

Food Industry Uses

- Noodles, ramen, and instant soups

- Bakery toppings for bread and buns

- Condiments in sauces and dips

- Ready-to-eat snacks

- Seasonings and spice blends

Export and Commercial Value

Fried garlic flakes and granules are in high demand in Southeast Asia, Middle East, Europe, and North America. Processed garlic products command higher market value compared to raw garlic.

Related Garlic Processing Machines

Garlic Peeling Machine for Pre-processing

Peeling is the first step of the production line. Air-powered peeling machines save time and minimize garlic waste.

Garlic Slicer and Cutter

Uniform slicing guarantees even frying, preventing burnt or undercooked pieces.

Garlic Drying Machine

Before frying, some production lines use hot air dryers to reduce moisture and save frying energy.

Garlic Seasoning Mixer

To add flavors such as salt, chili, or pepper, seasoning mixers coat the fried garlic evenly before packaging.

Maintenance and Operation Guidelines

Cleaning and Sanitation

Daily cleaning of frying tanks, conveyors, and filters prevents carbon buildup and oil contamination.

Oil Management

Regular oil filtration and replacement maintain taste consistency and prevent off-flavors.

Safety Precautions

Operators should be trained in handling hot oil, electrical controls, and emergency shut-off systems.

Spare Parts and After-Sales Support

Reliable manufacturers provide spare heating tubes, mesh conveyors, and filtration parts to ensure uninterrupted operation.

Request for Quotation (RFQ) for Garlic Frying Machines

When purchasing a crispy garlic flakes processing machine, buyers should provide the following details:

- Desired capacity (kg/h)

- Heating method (electric, gas, thermal oil)

- Voltage requirements

- Packaging style (bulk or retail packs)

- Automation level (semi-automatic or fully automatic line)

- Budget range

- Intended market (local sales or export)

- Installation and training requirements

- After-sales service expectations

- Certification requirements (CE, ISO, FDA compliance)

Crispy fried garlic granules flakes processing machine

The crispy fried garlic granules flakes processing machine is a vital investment for food processors aiming to produce high-quality garlic toppings and condiments. With its advanced automation, oil-saving technology, and consistent frying results, it ensures competitive advantages in the global food market. By integrating garlic peeling, slicing, frying, deoiling, cooling, and seasoning, manufacturers can achieve efficient production while meeting international quality standards.