Domates salçası gıda endüstrisinde yaygın olarak kullanılan bir malzemedir, ve bir kurulum domates salçası üretim hattı karlı bir iş olabilir. Bir plan yapıp yapmadığınız küçük ölçekli fabrika veya bir büyük ölçekli endüstriyel tesis, Anlamak üretim süreci, gerekli ekipman, ve maliyetler esastır. Bu kılavuz, domates salçası üretim işinize başlamak için bilmeniz gereken her şeyi size anlatacaktır..

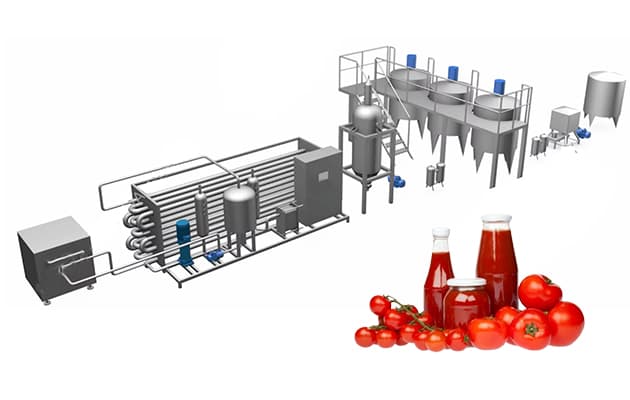

1. Domates Salçası Üretim Hattı Nedir??

A domates salçası üretim hattı taze domatesleri konsantre domates salçası haline getirmek için tasarlanmış bir makine sistemidir. Bu macun doğrudan paketlenip satılabileceği gibi ketçap hammaddesi olarak da kullanılabilir., soslar, ve diğer domates bazlı ürünler.

Domates Salçası Üretim Hattına Yatırım Yapmanın Temel Faydaları:

- Domates bazlı ürünlere yönelik yüksek pazar talebi

- İşlenmiş domates salçasının raf ömrü uzun

- Küçük ve büyük işletmeler için ölçeklenebilir üretim

- İhracat potansiyeli ve yüksek kar marjları

2. Domates Salçası Üretiminin Tüm Süreci

Adım 1: Yıkama & Sıralama

Taze domatesler kiri temizlemek için iyice yıkanmalıdır., pestisitler, ve diğer kirleticiler. Ayırma makineleri, yüksek kaliteli domatesleri kusurlu olanlardan ayırmaya yardımcı olur.

Gerekli Ekipman: Çamaşır makinesi, Sıralama makinesi

Adım 2: Ezici & Ön ısıtma

Seçilen domatesler ezilerek posa haline getirilir ve enzimleri devre dışı bırakmak ve renk korumasını arttırmak için önceden ısıtılır..

Gerekli Ekipman: Kırıcı, Ön ısıtıcı

Adım 3: Kağıt hamuru çıkarma & Rafine etme

Domates posası kabukları çıkarmak için rafine edilir, tohum, ve lifli malzeme, pürüzsüz ve tutarlı bir macun sağlamak.

Gerekli Ekipman: Pulper, Sonlandırıcı

Adım 4: Konsantrasyon & Buharlaşma

Ekstrakte edilen domates posası, fazla suyun uzaklaştırılması için bir buharlaştırıcıda ısıtılır., yüksek katı madde içeriğine sahip konsantre domates salçası elde edilir (tipik olarak 28%-30%).

Gerekli Ekipman: Vakum buharlaştırıcısı

Adım 5: Sterilizasyon & Aseptik Dolum

Raf ömrünü uzatmak için, macun yüksek sıcaklıklarda sterilize edilir ve daha sonra paketlenir aseptik torbalar, teneke kutu, veya cam kavanozlar.

Gerekli Ekipman: Sterilizatör, Aseptik dolum makinası

Adım 6: Ambalajlama & Etiketleme

Nihai ürünler pazar ihtiyaçlarına göre farklı boyutlarda paketlenir, daha sonra etiketlendi ve dağıtıma hazırlandı.

Gerekli Ekipman: Paketleme makinesi, Etiketleme makinesi

3. Domates Salçası Üretim Hattı İçin Temel Ekipmanlar

| Teçhizat | İşlev |

|---|---|

| Çamaşır makinesi | Taze domatesleri temizler |

| Ayırma Makinesi | İyi domatesleri kusurlu olanlardan ayırır |

| Kırıcı | Domatesleri ezerek posa haline getirir |

| Ön ısıtıcı | Rengi ve kıvamı iyileştirmek için hamuru ısıtır |

| Pulper & Sonlandırıcı | Tohumları ve cildi çıkarır |

| Buharlaştırıcı | Domates salçası konsantresi |

| Sterilizatör | Bakterileri öldürür ve raf ömrünü uzatır |

| Aseptik Dolum Makinesi | Paketler steril kaplara yapıştırılır |

| Ambalaj makinesi | Nihai ürünleri satışa hazırlar |

4. Doğru Domates Salçası Üretim Hattı Nasıl Seçilir?

Ekipman seçerken, aşağıdaki faktörleri göz önünde bulundurun:

1. Üretim kapasitesi

- Küçük ölçekli: 100-500 kg/s

- Orta ölçekli: 500-2,000 kg/s

- Büyük ölçekli: 2,000+ kg/s

2. Otomasyon seviyesi

- Yarı otomatik: Daha düşük maliyet, daha fazla el emeği gerekli

- Tam otomatik: Daha yüksek verimlilik, asgari emek katılımı

3. Güç Kaynağı & Isıtma yöntemi

- Elektrikli ısıtma: Endüstriyel 3 fazlı güç gerektirir

- Gazlı ısıtma: Sınırlı elektrik arzına sahip bölgeler için uygundur

5. Domates Salçası Üretim Hattı Maliyeti

Toplam maliyet üretim kapasitesine bağlıdır, ekipman kalitesi, ve otomasyon seviyesi. İşte tahmini fiyat aralığı:

| Üretim Ölçeği | Tahmini maliyet (Amerikan Doları) |

| Küçük Ölçekli (100-500 kg/s) | $10,000 – $50,000 |

| Orta Ölçekli (500-2,000 kg/s) | $50,000 – $500,000 |

| Büyük Ölçekli (2,000+ kg/s) | $500,000 – $2,000,000 |

Ek maliyetler şunları içerir::

Bakım ve yedek parçalar

İşlenmemiş içerikler (domates, ambalaj malzemeleri)

İşçilik ve fabrika kurulumu

6. Sık sorulan sorular (SSS)

Çeyrek: Domates salçası üretim hattı için ne kadar alana ihtiyaç vardır??

- Küçük ölçekli bir tesis faaliyet gösterebilir 200-500 metrekare, büyük bir endüstriyel kurulum gerektirebilirken 2,000+ metrekare.

Çubuk: Otomatik üretim hattıyla başlayabilir miyim??

- Evet, Tam otomatik üretim hattı iyi bir seçimdir, işçilik maliyetlerinden tasarruf

Çeyrek: Domates salçası için en iyi paketleme seçeneği nedir?

- Popüler seçenekler arasında aseptik torbalar bulunur (200L), teneke (70g-5kg), ve cam kavanozlar (300g-1kg).

Çeyrek: Domates salçası ne kadar dayanır?

Uygun sterilizasyon ve paketleme ile, domates salçası dayanabilir 12-24 aylar.

7. Sonuç – Domates Salçası Üretim Hattınızı Bugün Alın!

Bir kurulum domates salçası üretimi Line, artan pazar talebiyle karlı bir yatırımdır. İster küçük ölçekli işleme, ister büyük ölçekli endüstriyel üretim arıyor olun, Doğru ekipmanın ve kurulumun seçilmesi çok önemlidir.

🚀 Kendi domates salçası işinizi kurmak istiyorsanız? DT Gıda Makinası ile bugün iletişime geçin özelleştirilmiş bir üretim çözümü ve ücretsiz fiyat teklifi için!

📩 Şimdi Ücretsiz Teklif Alın!